TMS / TSI

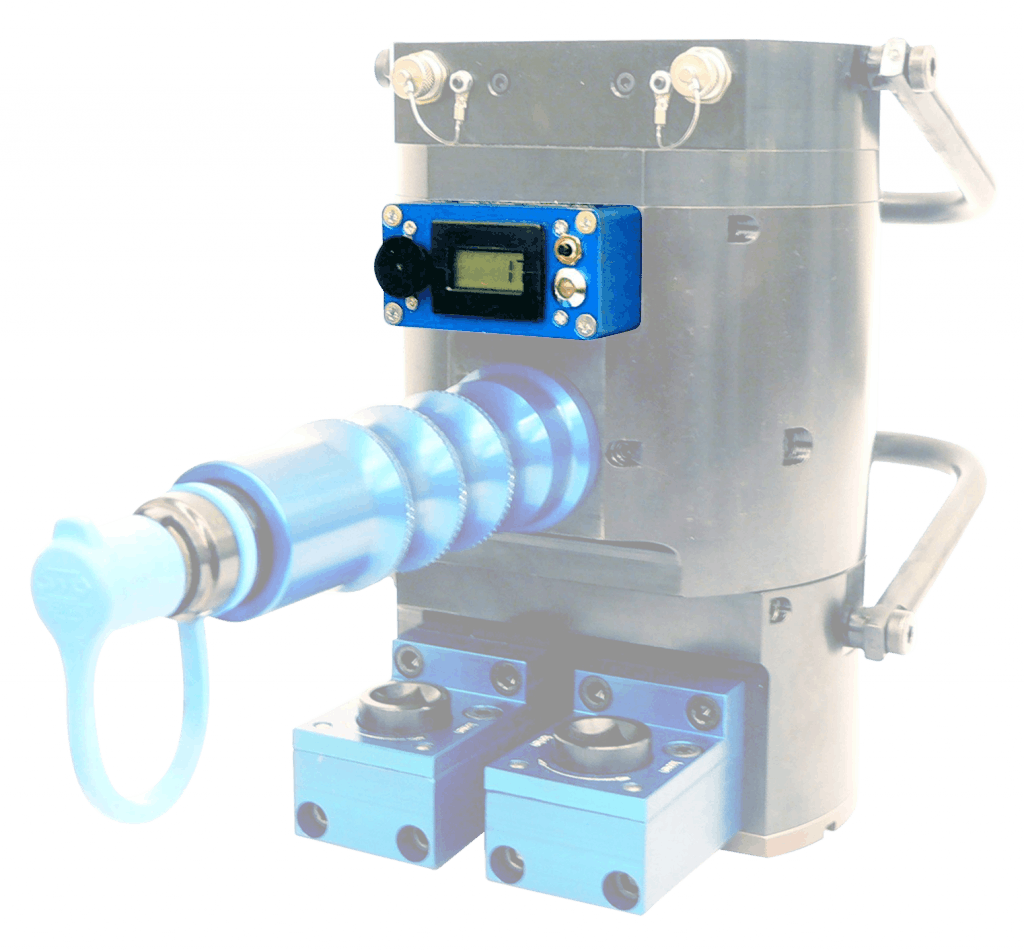

Tool-Management-System and Tool-Service-Indicator for operation and maintenance monitoring of hydraulic tools and aggregates

for monitoring the maintenance intervals of hydraulic tools, hydraulic pressure generators, high-pressure hoses and their accessories.

- Maintenance reminder after time period (e.g. pressure gauge calibration)

- Monitoring load cycles

- Warning before the maximum number of load cycles is reached (e.g. bolt tensioners) and end of service life (e.g. high-pressure hoses)

- Recording of new tools and applied tools, pressure units and accessories

- Inventory database of all available tools, pressure units and accessories

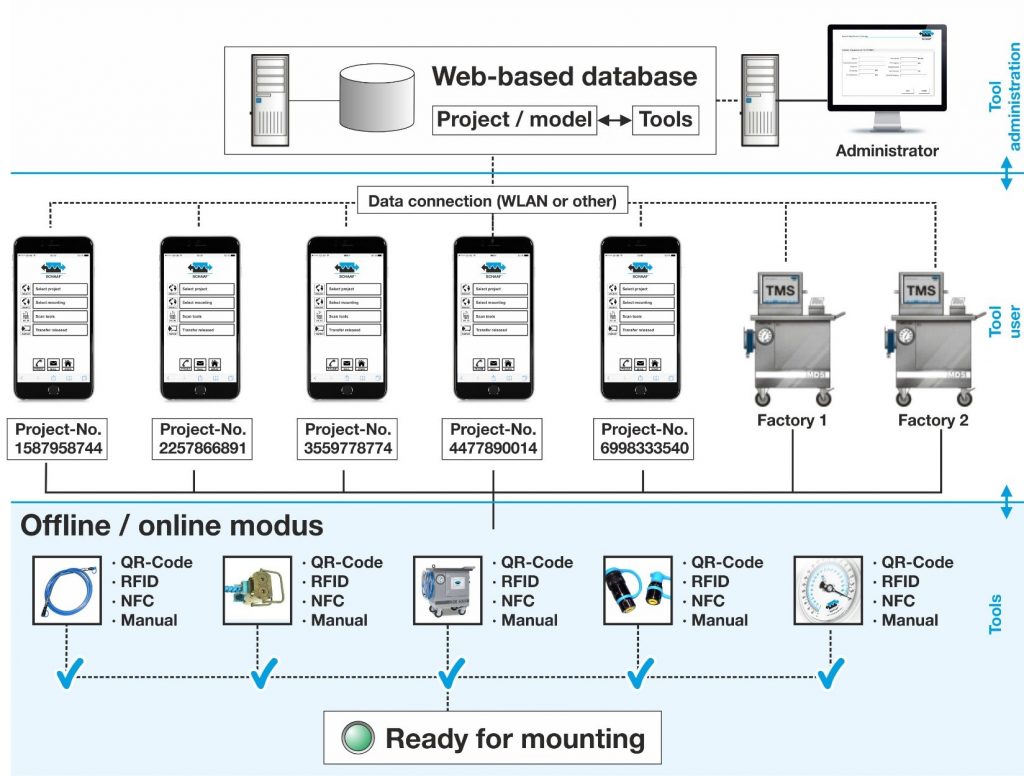

- Database communication via WLAN or other connections

优点

- 100% documentation of the load changes

- Maximum safety precautions through compliance with the prescribed maintenance intervals

- User-friendly interfaces designed according to customer specifications

- No loading possible if the prescribed load changes are exceeded (TMS only)

- Password-protected parameter entry

- Advance warning of upcoming maintenance, with stock connection and ordering system on request

- Logged load changes of all tools

- Increased service life of components due to wear reduction of new spare parts

- Inventory management of all existing tools

- Minimisation of failures during operation

- Minimisation of consequential damage to the components to be clamped due to smooth operation

Network diagram

Central, relational database for storing and monitoring all configurations, load changes, lifetimes and maintenance intervals

标准配置

The SCHAAF TMS / TSI can be extended with the following options, among others:

- Central server solution for synchronisation of several TMS systems

- Various backup media

- Warehouse management

- Evaluation of load changes

- Barcode scanner

- Optional software for MDS and STG

- All conceivable special versions are possible. Please let us know your requirements.

应用领域

The SCHAAF TMS / TSI prove themselves in the:

- Bolt tensioning force generation, where 100% functional sequence and safety is required.

- SCHAAF accessories where intervals are logged and an overview of all tools requiring maintenance must be available.

质量保证

All TMS / TSI systems are tested for 100% process reliability. During order processing, they are accompanied by ongoing quality assurance measures and supplied with detailed documentation.

服务

The SCHAAF TMS / TSI are user-friendly, safe and correspond to the highest technical know-how. Our highly motivated staff will be happy to train your personnel in the use of the control and regulation system and general interrelationships in the press bracing process on site or in our factory. Thus, all process parameters can be optimally entered in order to achieve maximum process monitoring and safety.

Of course, the TMS / TSI are delivered ready for operation.