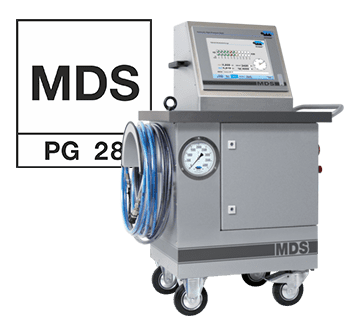

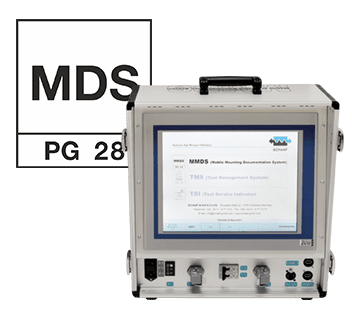

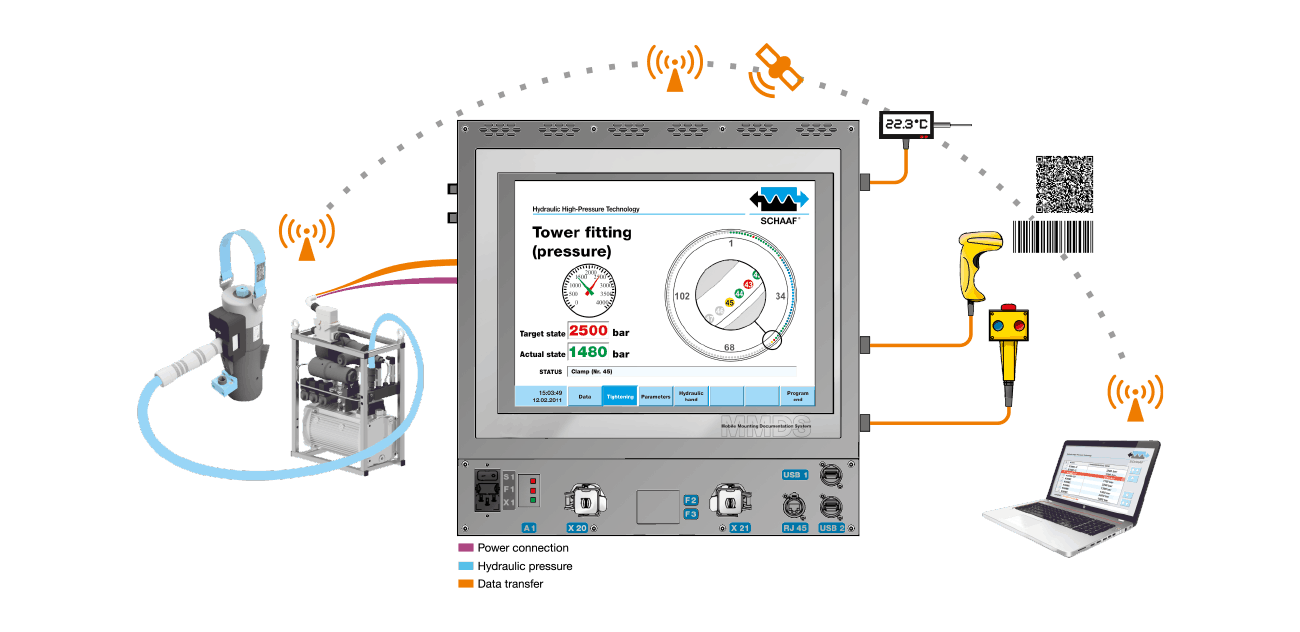

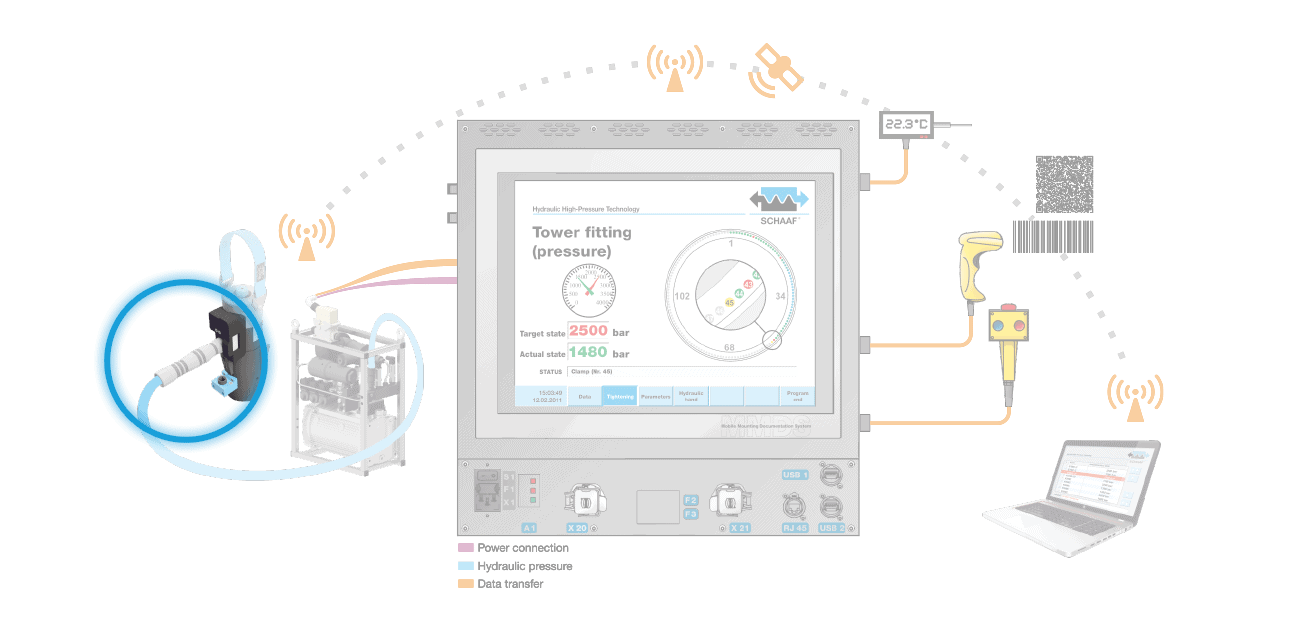

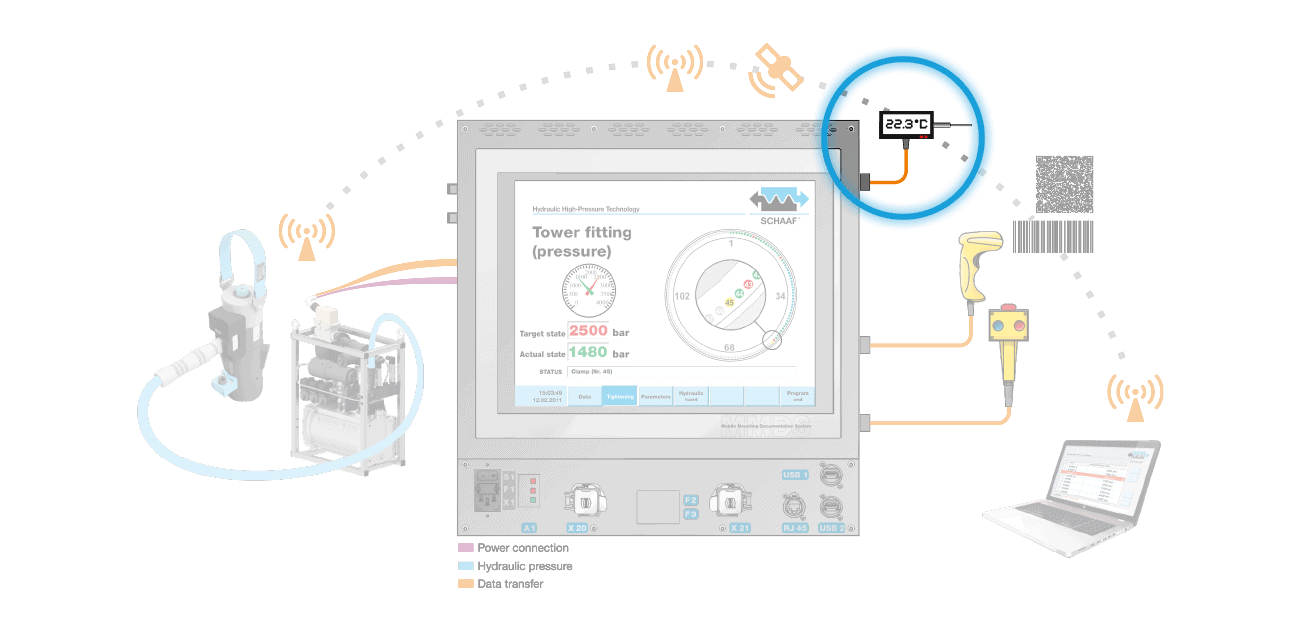

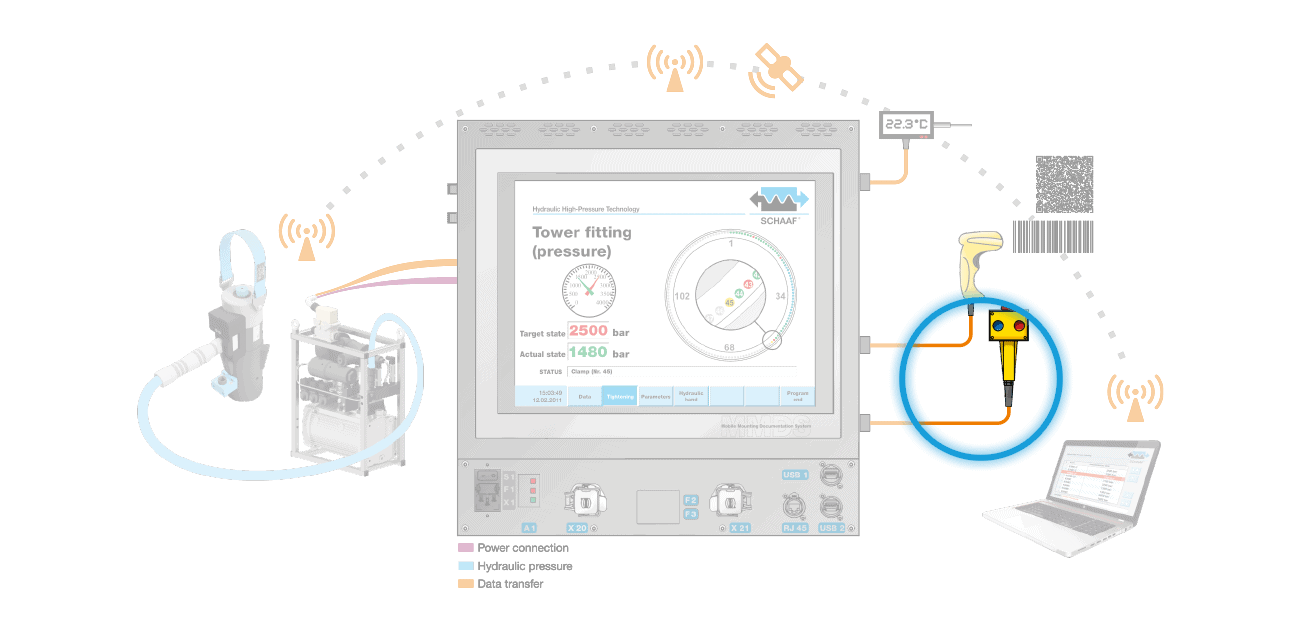

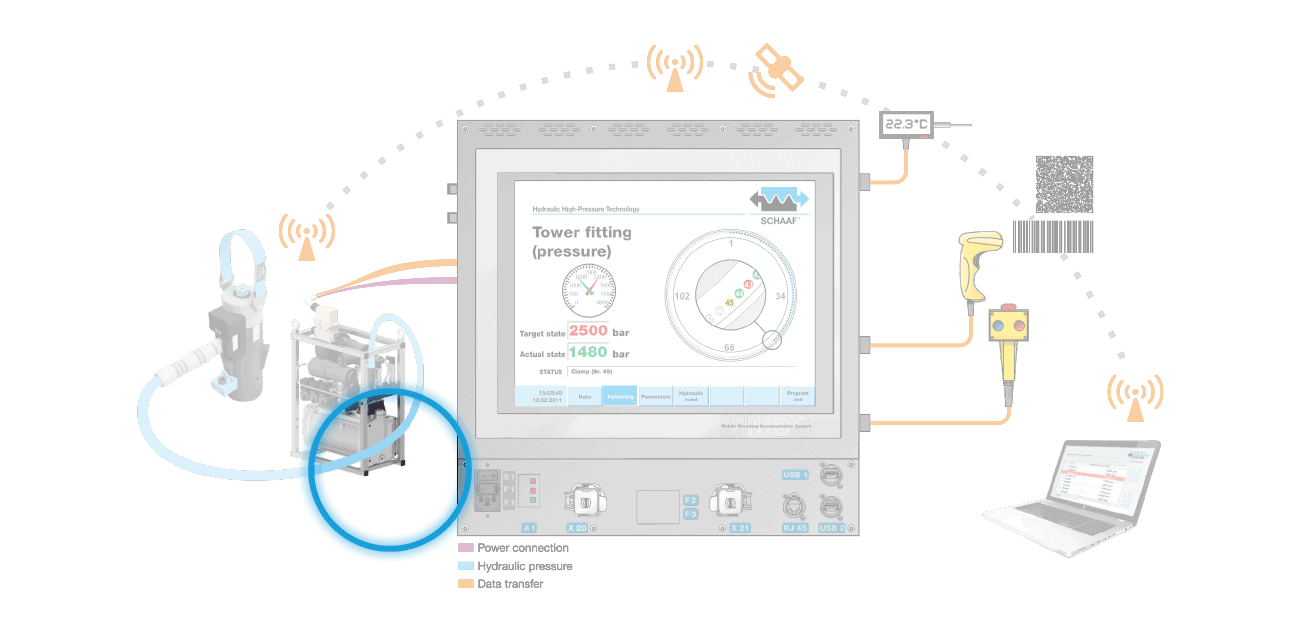

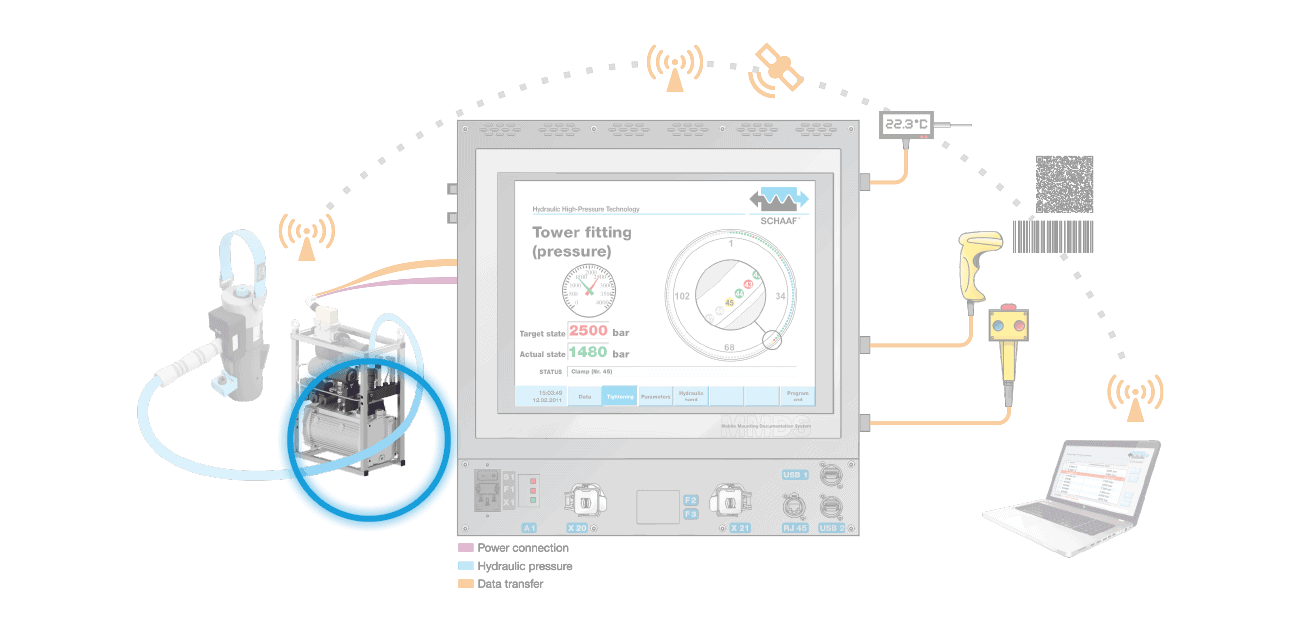

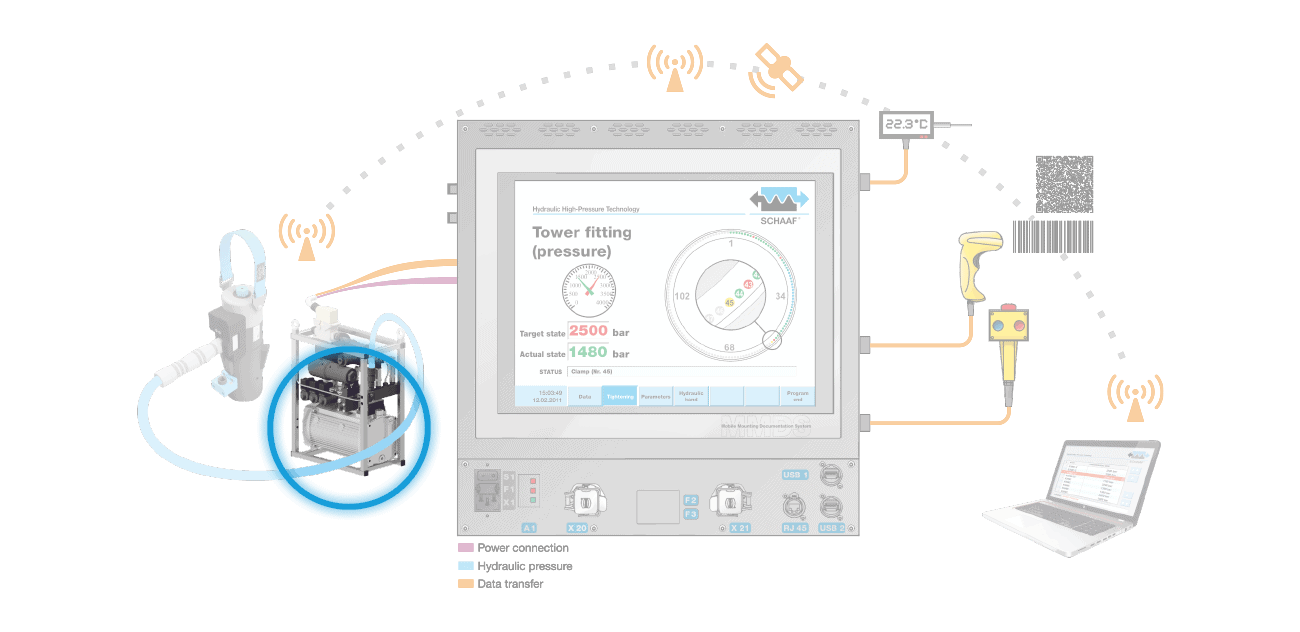

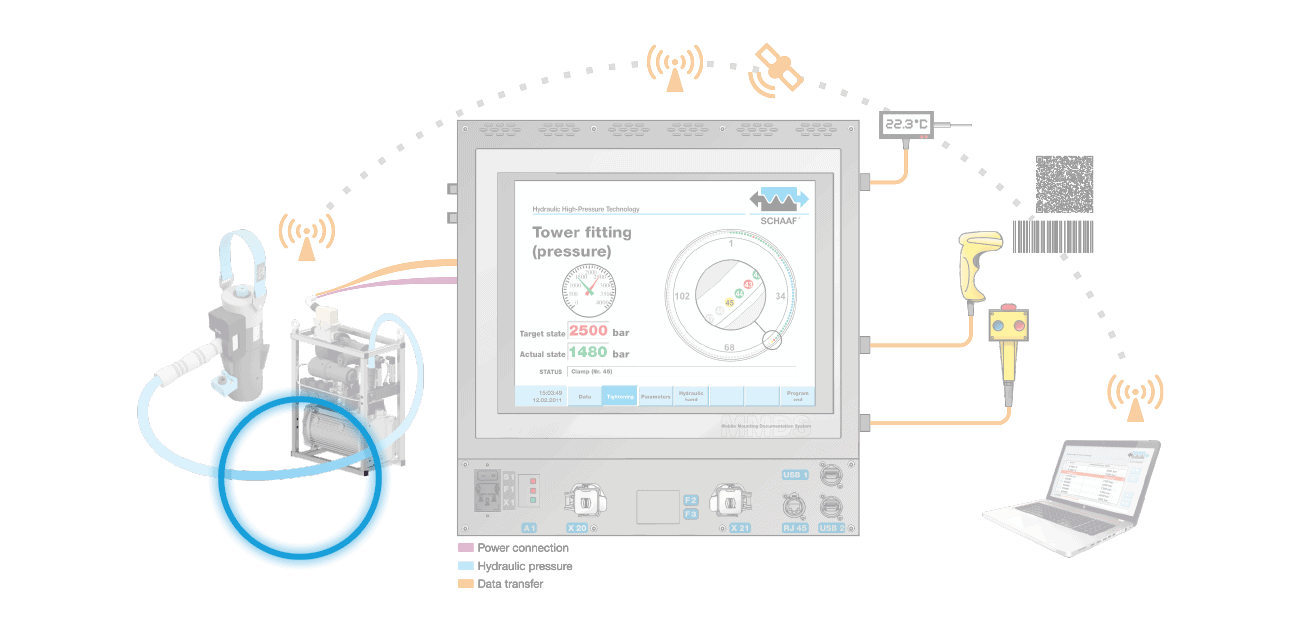

MMDS

Mobile Mounting Documentation System – Full data recording of residual bolt load, bolt elongation and flange compression

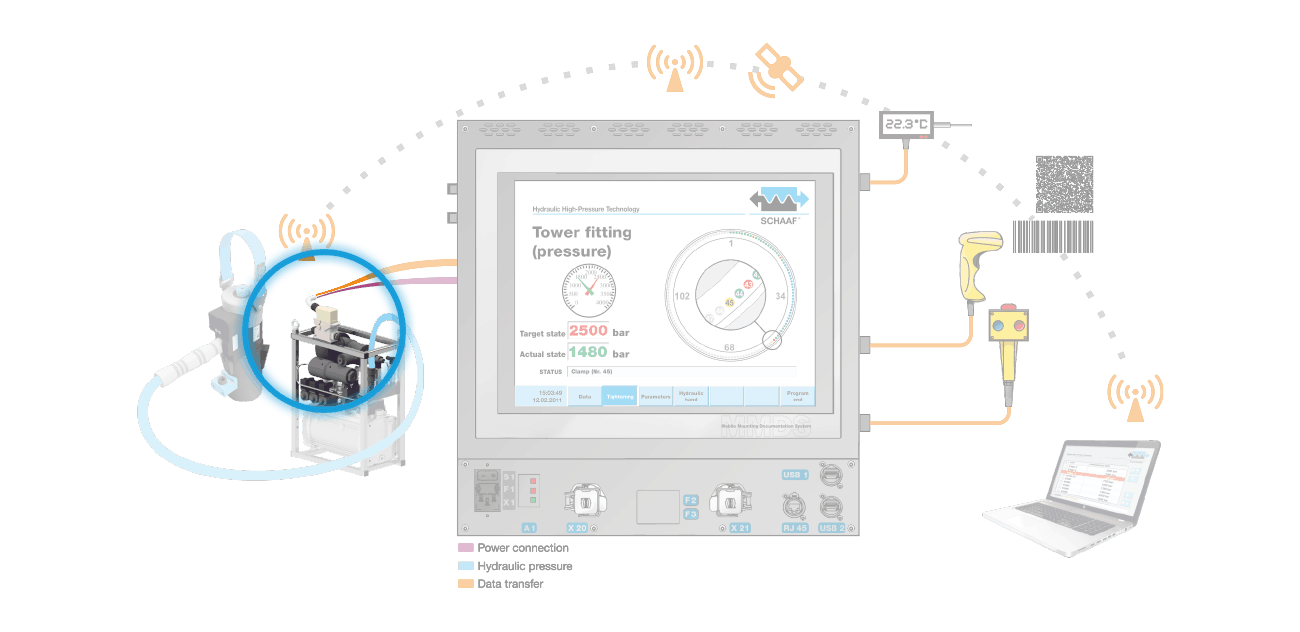

SCHAAF Bolt Tensioner,

2,500 bar working pressure with integrated wireless measuring functions.

Industrial connector to MMDS.

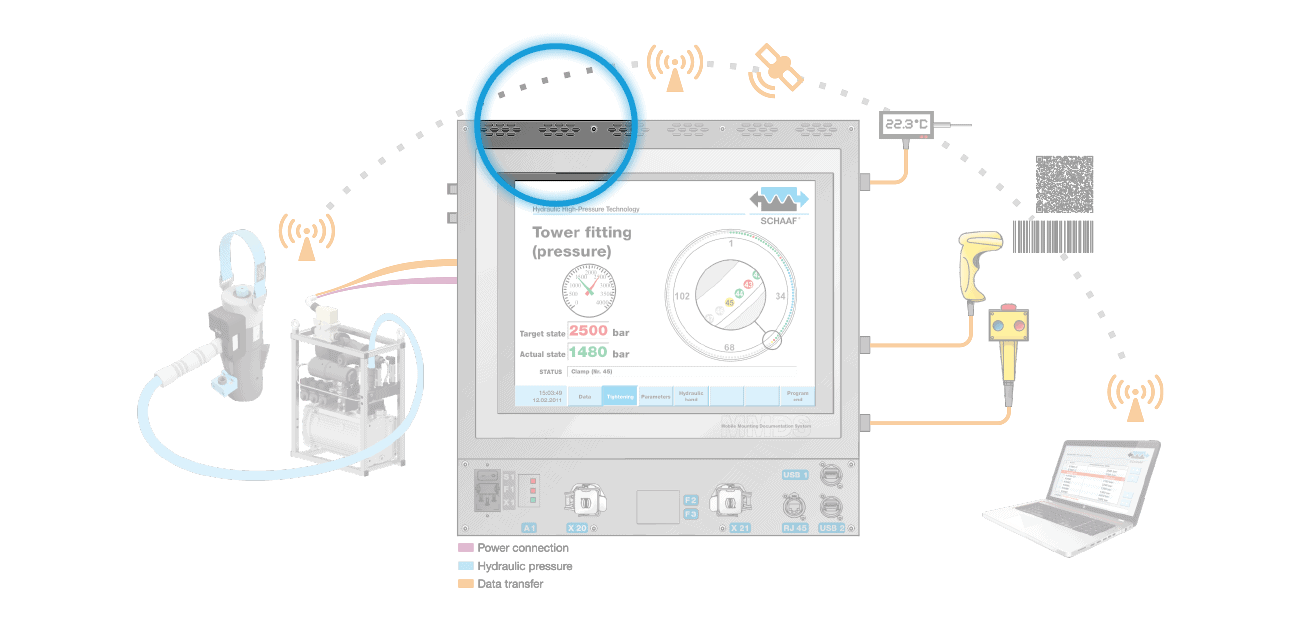

Basic MMDS

with TFT Touch screen and IP65.

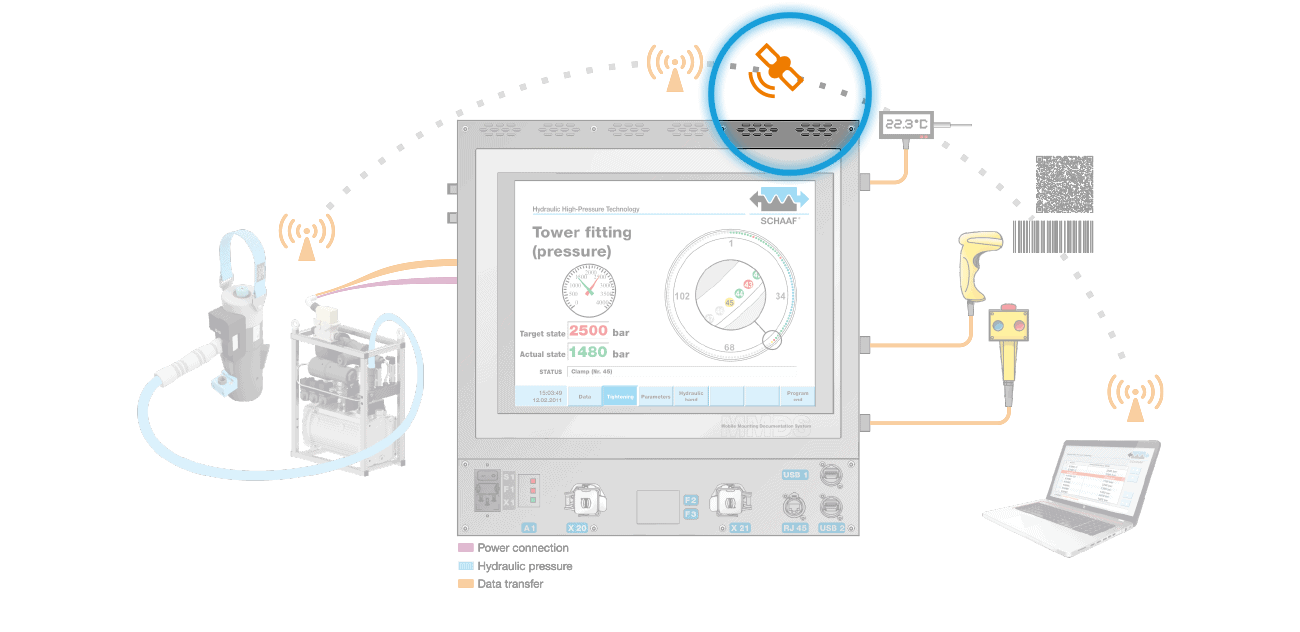

GPS receiver

for global tracking (Option)

Temperature sensor.

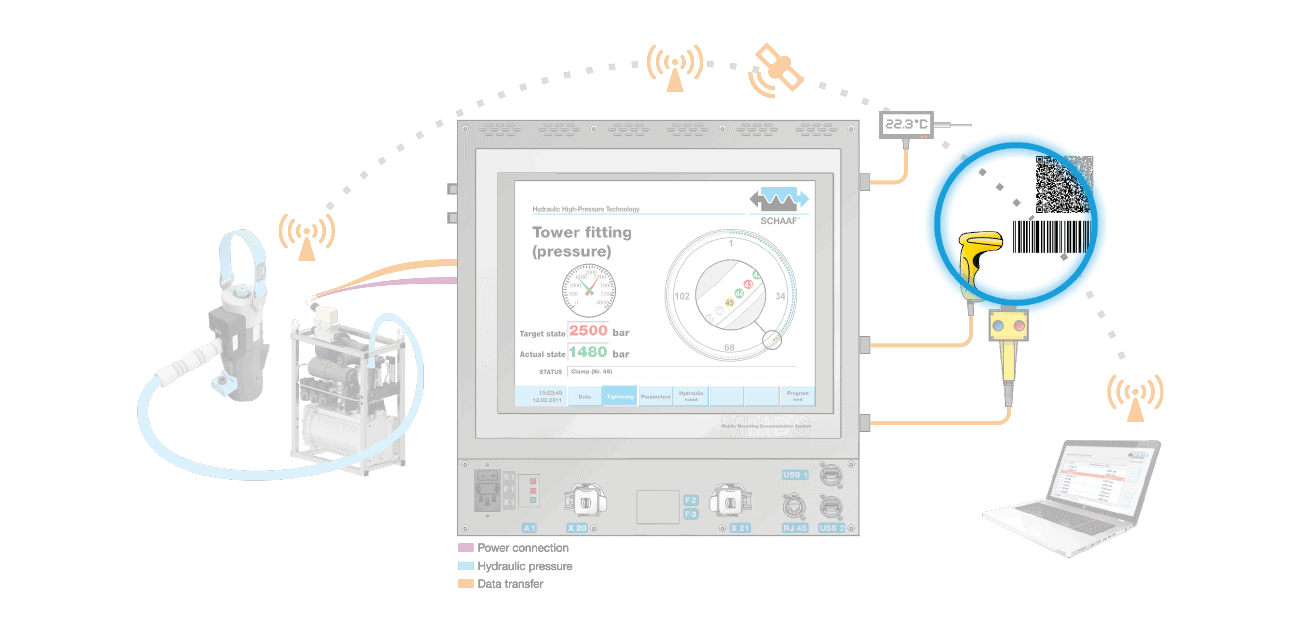

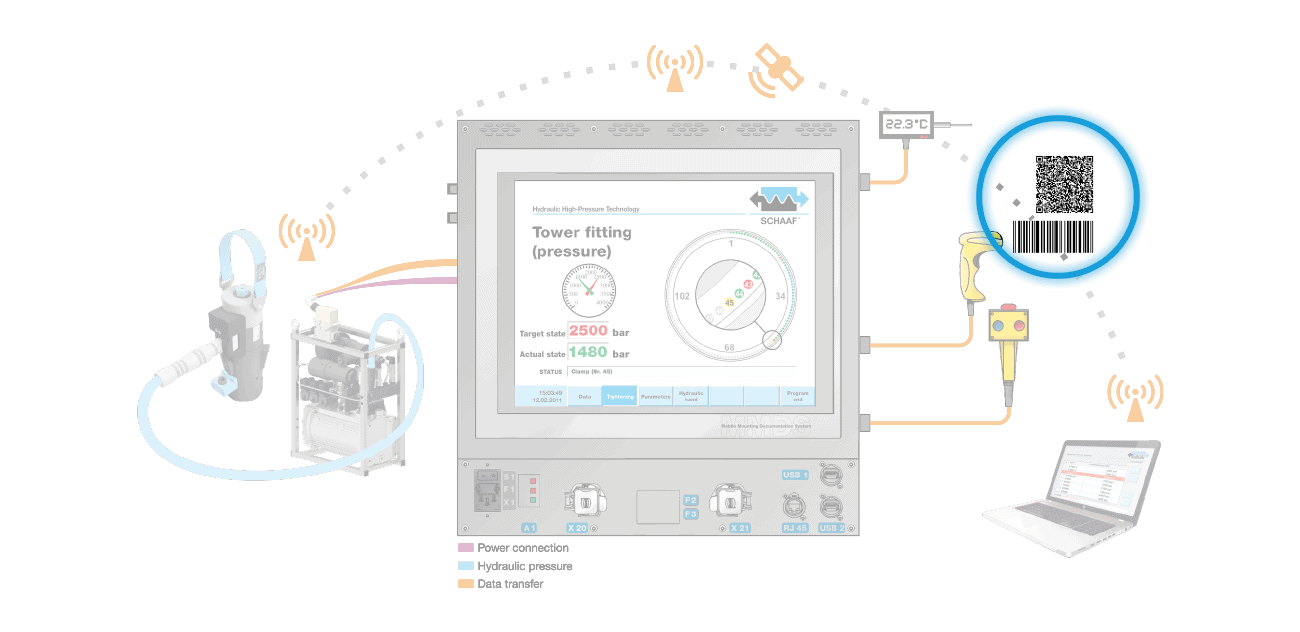

Scanner

Barcode / QR

for data acquisition (Application/ Tool).

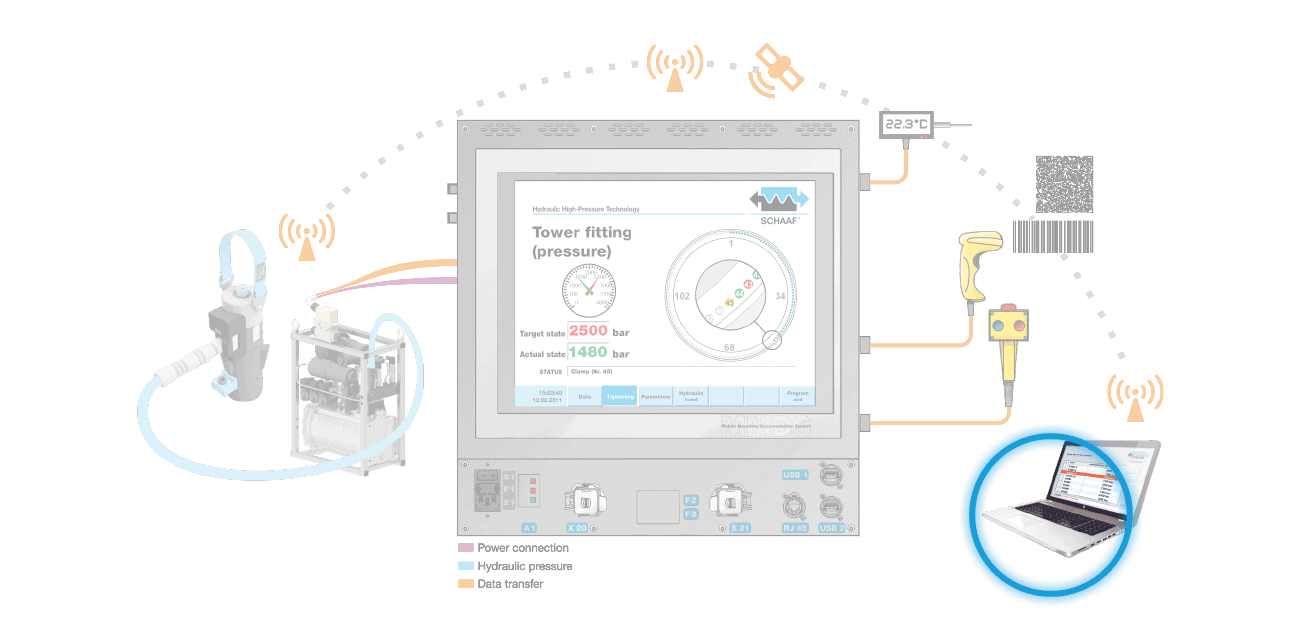

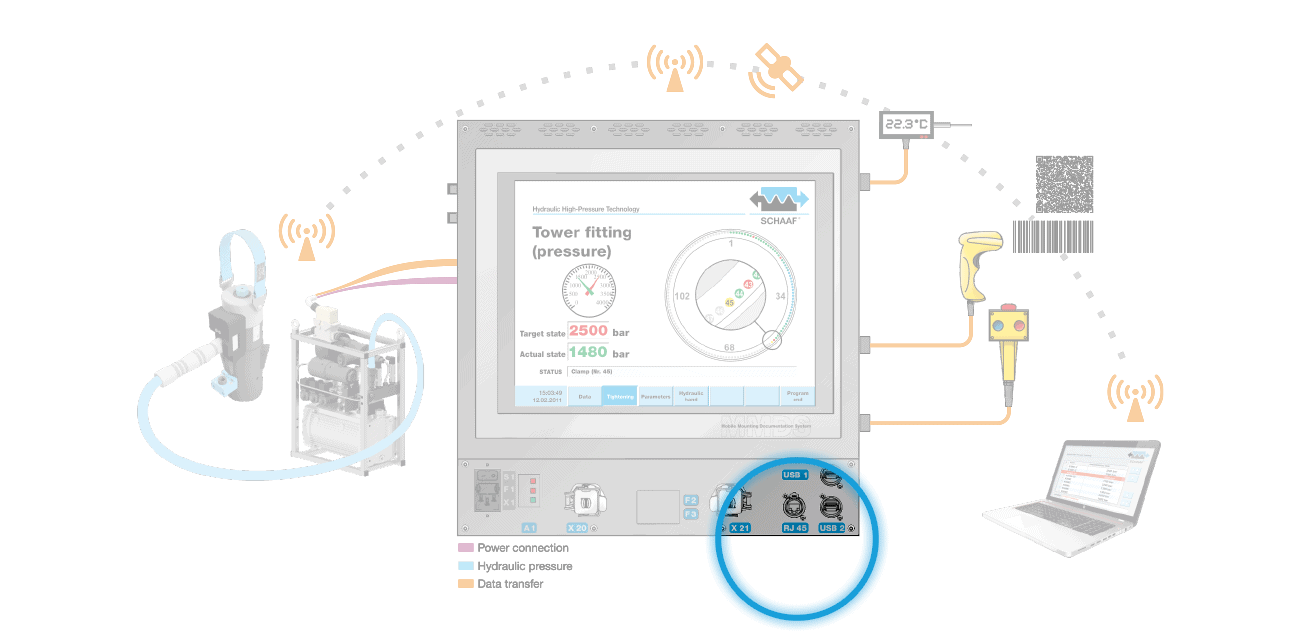

PC / Laptop interface

for data storage and processing via WLAN.

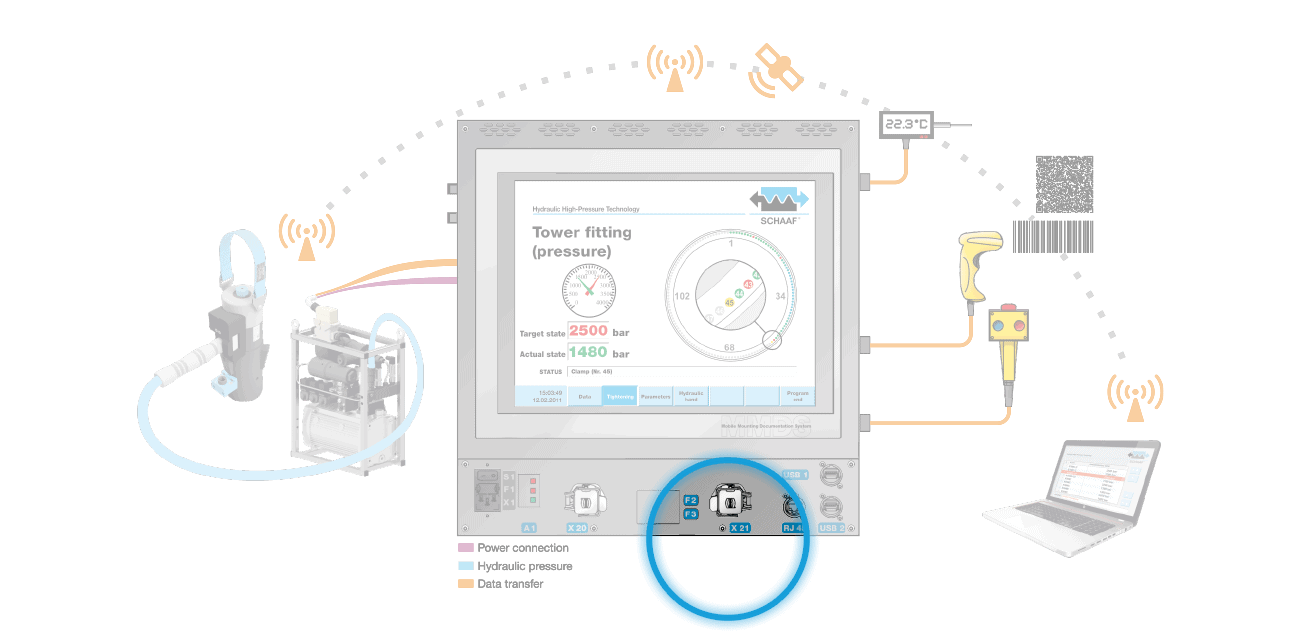

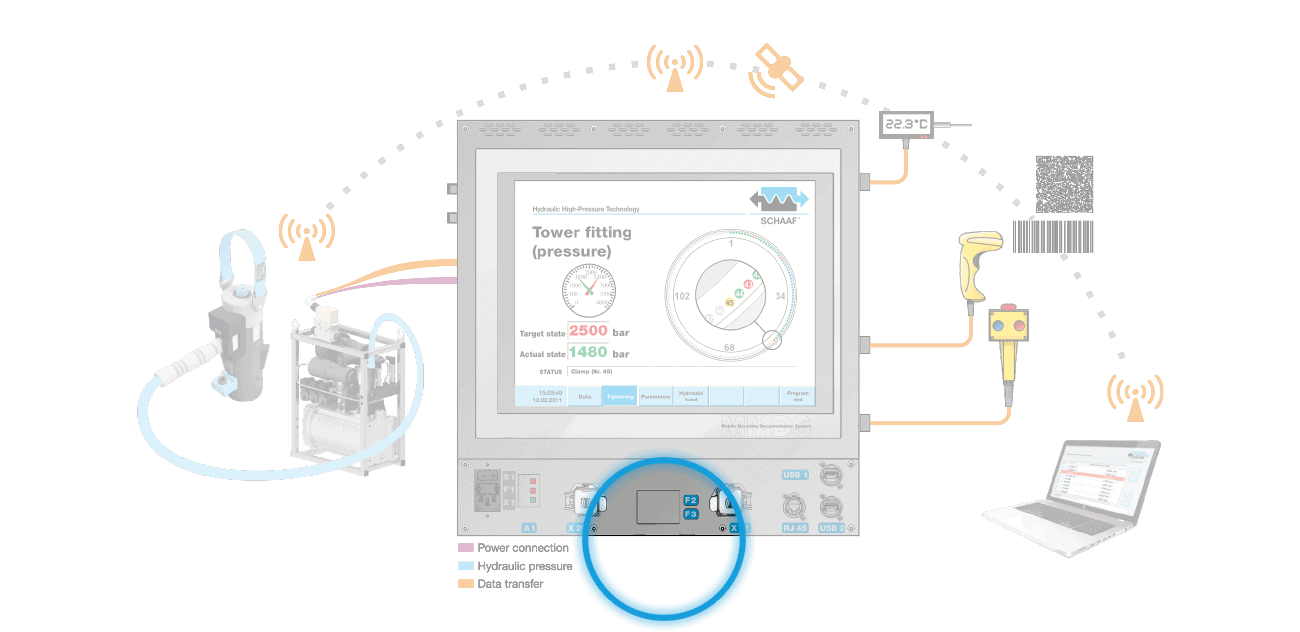

Remote control

for pump unit.

Grid Power Supply:

230V – 50Hz orcustomized.

Stable, mobile casing.

Optionally:

· Tool Management System (TMS)

· TSI Tool Service Indicator (TSI)

· Global Tracking (GT)

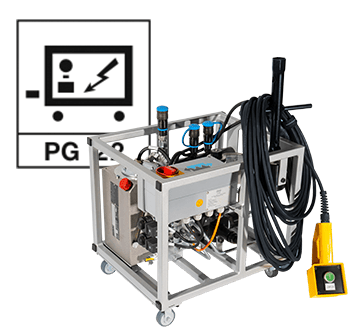

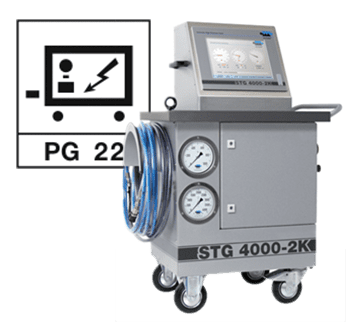

Electric hydraulic pump unit

(air-driven or handlever pump are also possible) with 2,500 bar pressure.

Internal redundant pressure transducers.

Heater / Cooler

High-pressure hose

with coupling system for pressure up to 2,500 bar.

优点

- 螺栓连接质量100%文档记录

- 电脑能记录、显示、记忆和打印 螺栓伸长量和法兰压缩量数据

- 由于压力和拉伸量得到持续的监控,工作的安全性大大提高

- 简洁、舒适的用户界面

- 据输出在客户的质量保证表单上

- 螺栓拉伸系统的紧固程序几乎可无限量存储

- 拉伸程序和报告可通过USB或LAN接口传输

- 使用寿命长和便于维护

- MMDS的自我监控

- 可通过外接电源或自备电池模式下工作

- 可与任何类型的泵配合使用

- 带手柄的可运输的铝合金外箱

高压装置

标准配置

- Colour or B+W printer

- Radio-operated remote controller with display

- LAN/W-LAN/USB interface

- Remote access for remote maintenance

- TMS interface (Tool Management System)

- TSI interface (Tool Service Indicator)

- Radio-operated sensors

- Sensors integrated in the bolt tensioners or supplied

- separately

- Central specification of bolting data via SAP interface, database, USB interface or copy and paste

- 1-3K design type for separate control of multiple independent pressure circuits

- Rotation angle and torque control for bolt tensioners with automated motorised re-tightening function

- Optional colour coding of the used equipment

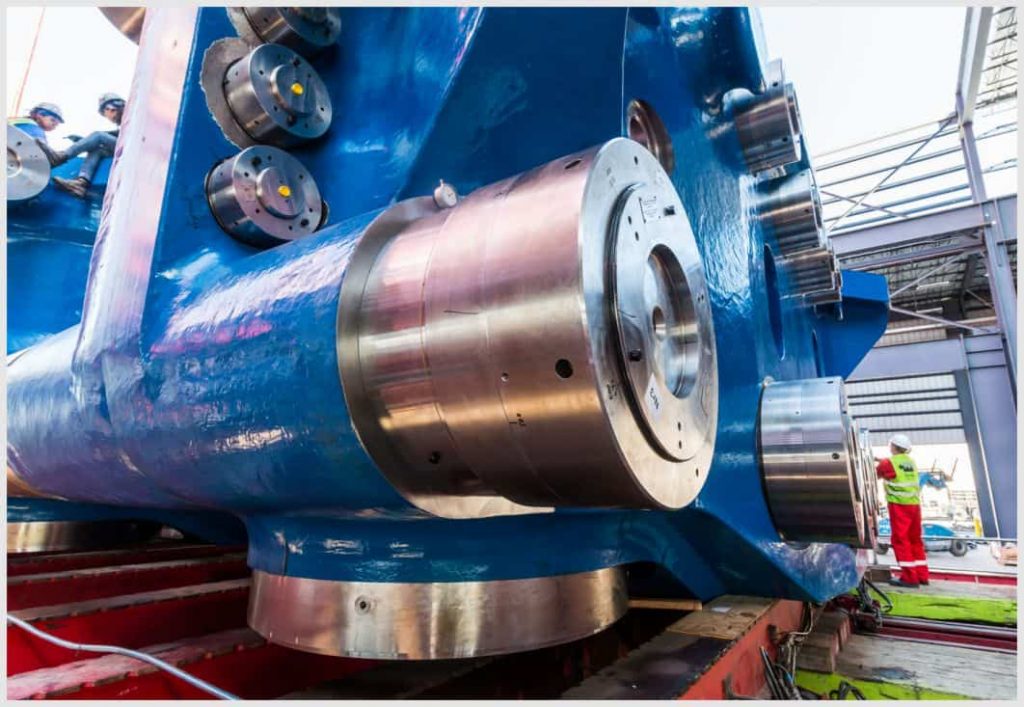

应用领域

SCHAAF MMDS is ideally suited for:

- Generating a bolt pre-tensioning force for which 100% operational sequencing, safety and data logging are required.

- Engine-building: Main bearing, connecting rod bearing, cylinder head

- Power plants: e.g. Turbines, compressors

- Ring gear bolt connections: e.g. wind power plants

- Tower fittings: e.g. crane construction

- General mechanical engineering

服务

SCHAAF MMDS界面友好,便于使用,性能可靠;所有

的过程参数都可进行最优化输入,以获得最大程度的拉

伸过程监控和最大安全性,其设计及制造工艺均体现了

SCHAAF在该领域的先进技术水平。我们经验丰富的工程

师很乐意提供现场的培训服务。当然,所供应的 MMDS 交

付时即可投入使用。