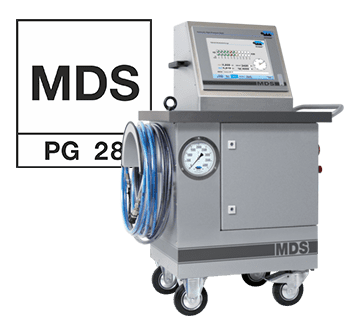

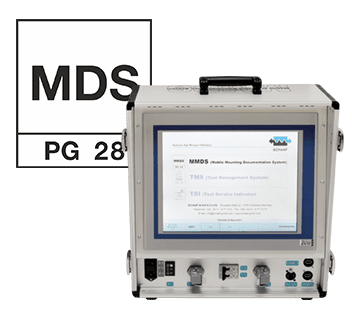

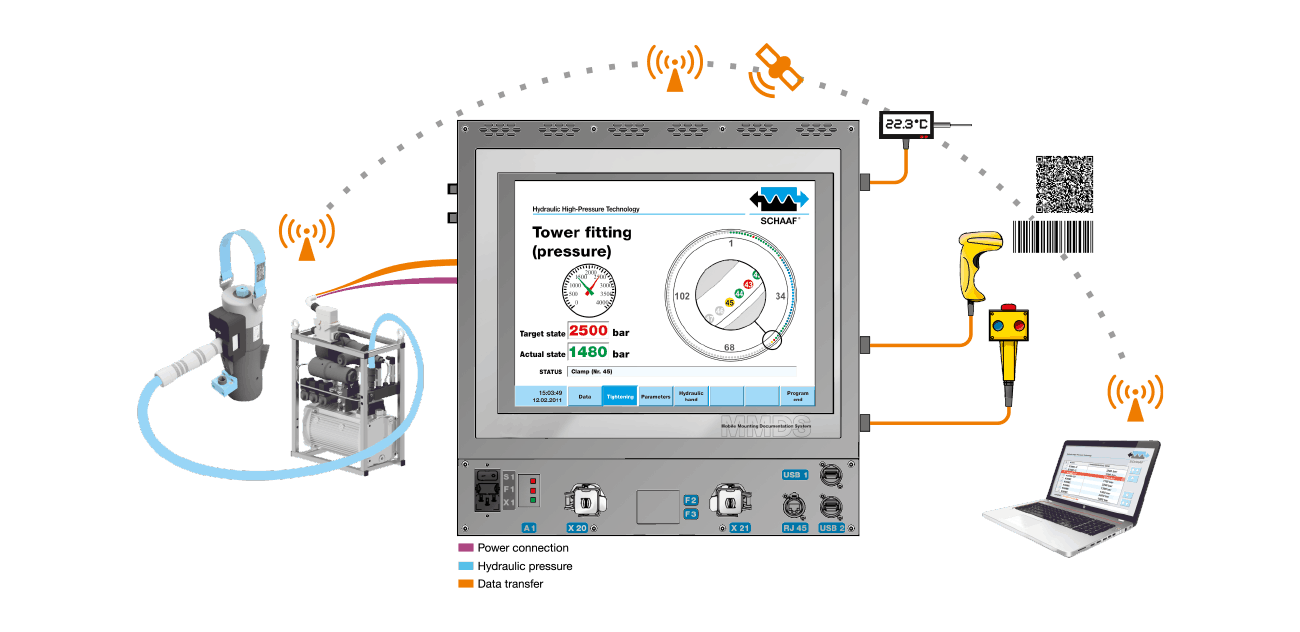

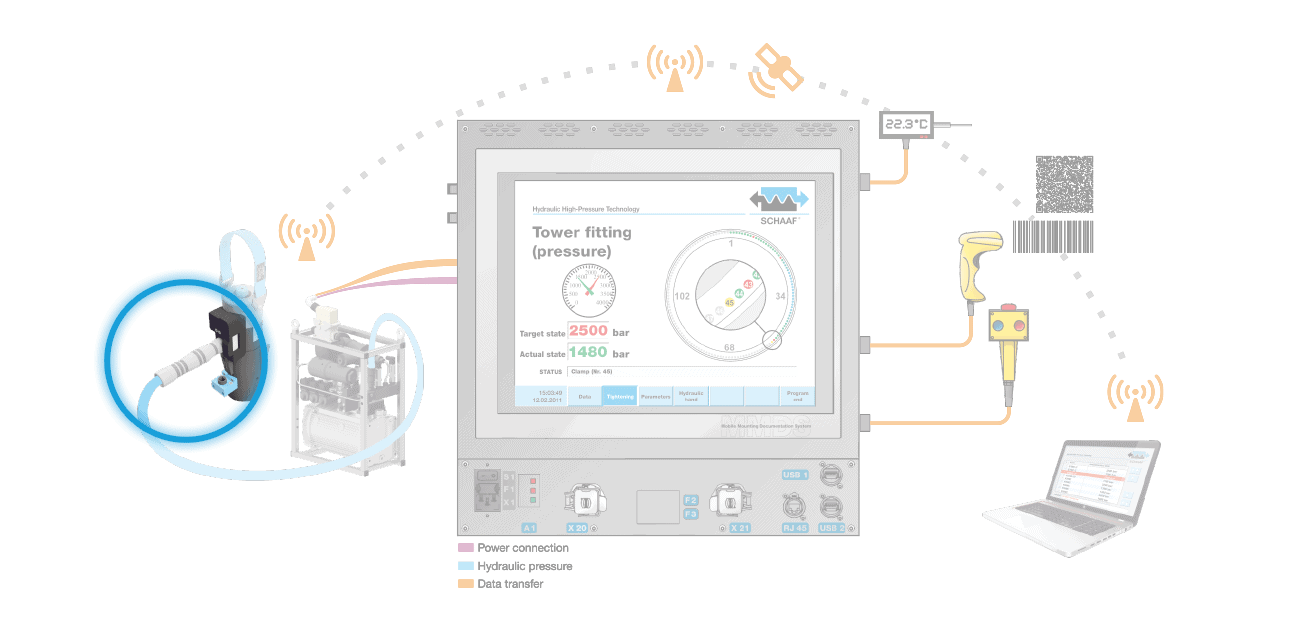

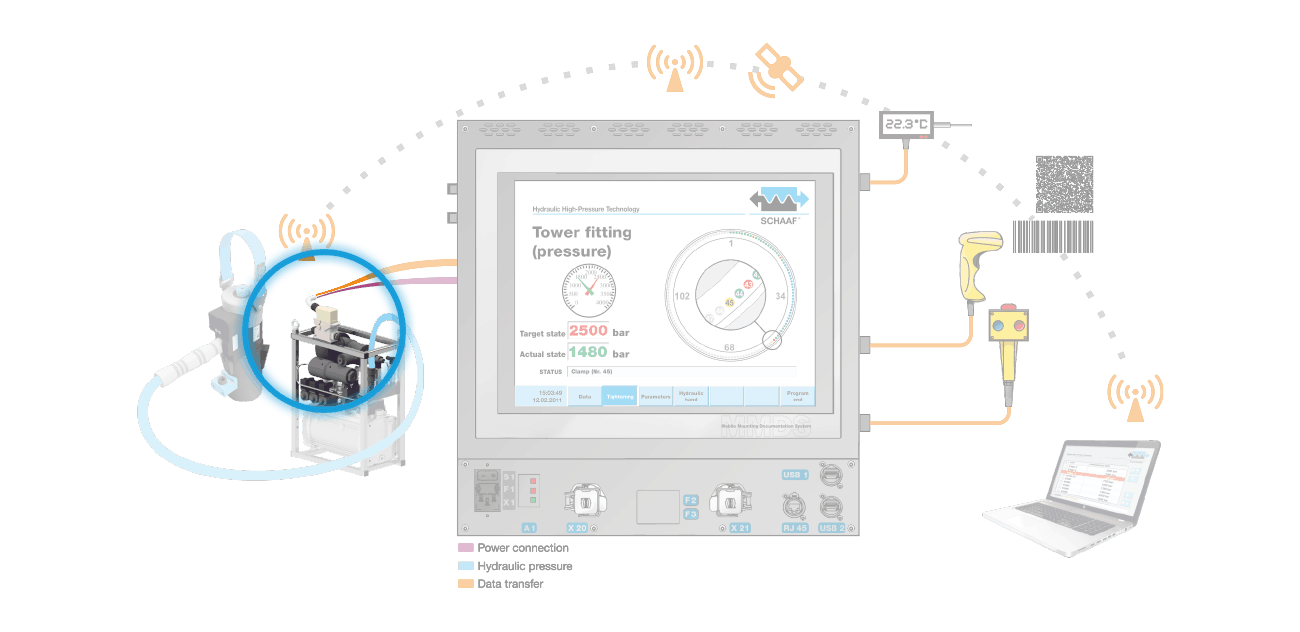

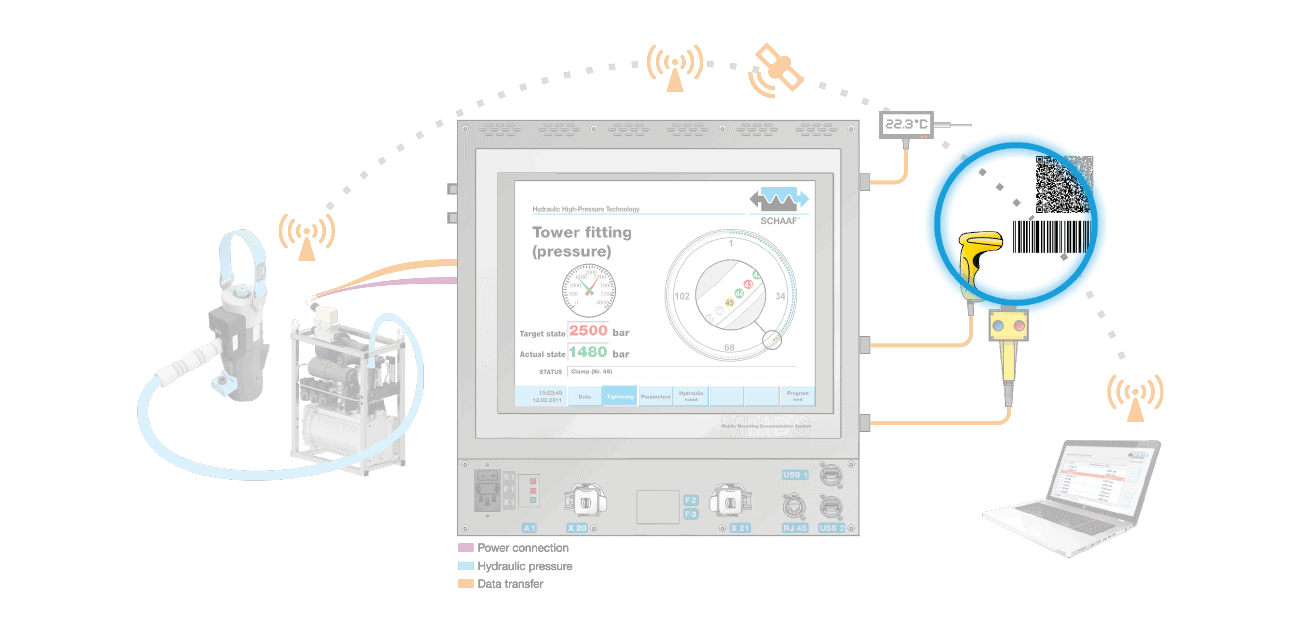

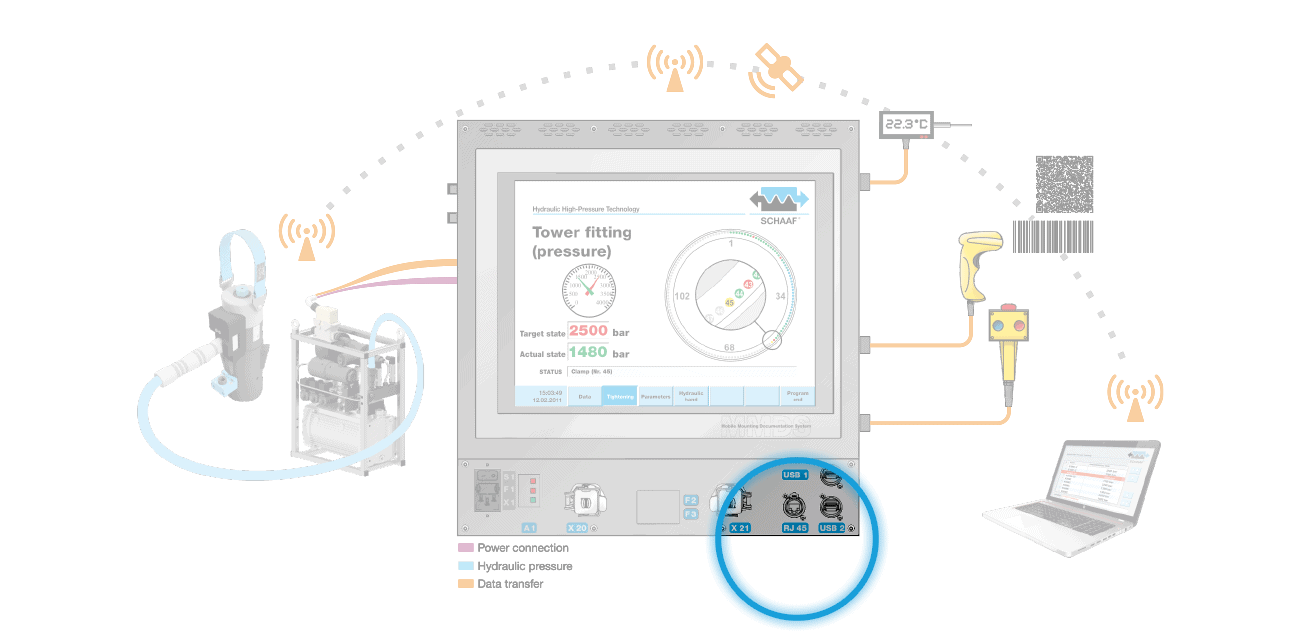

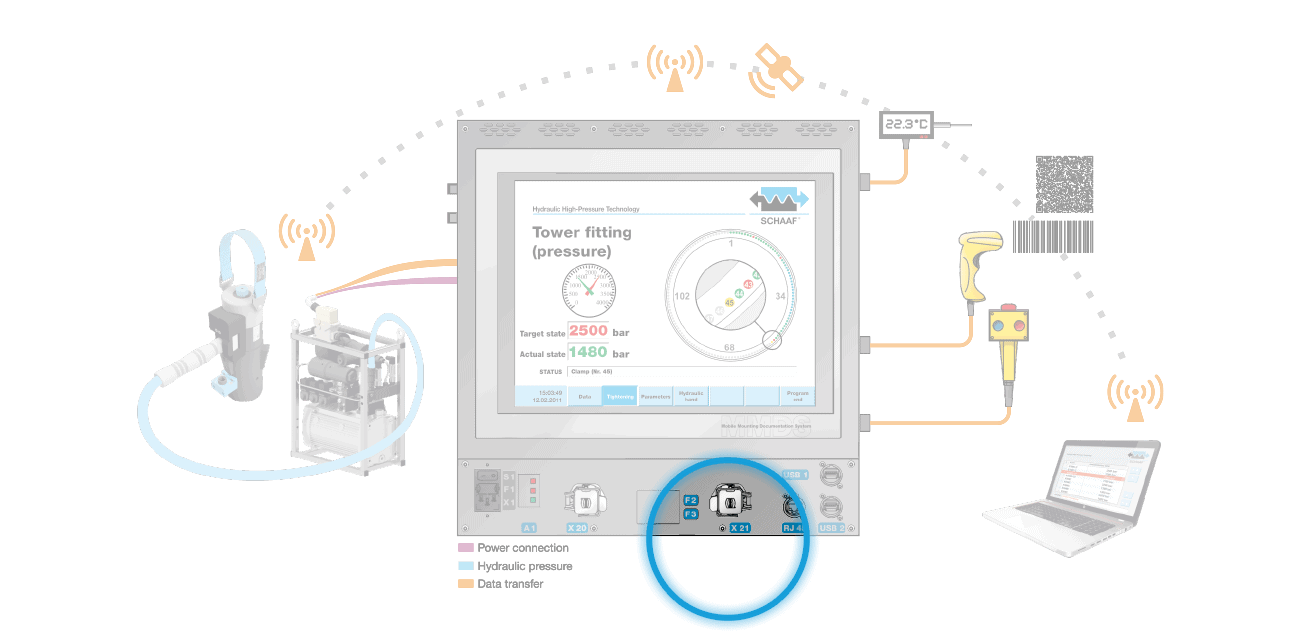

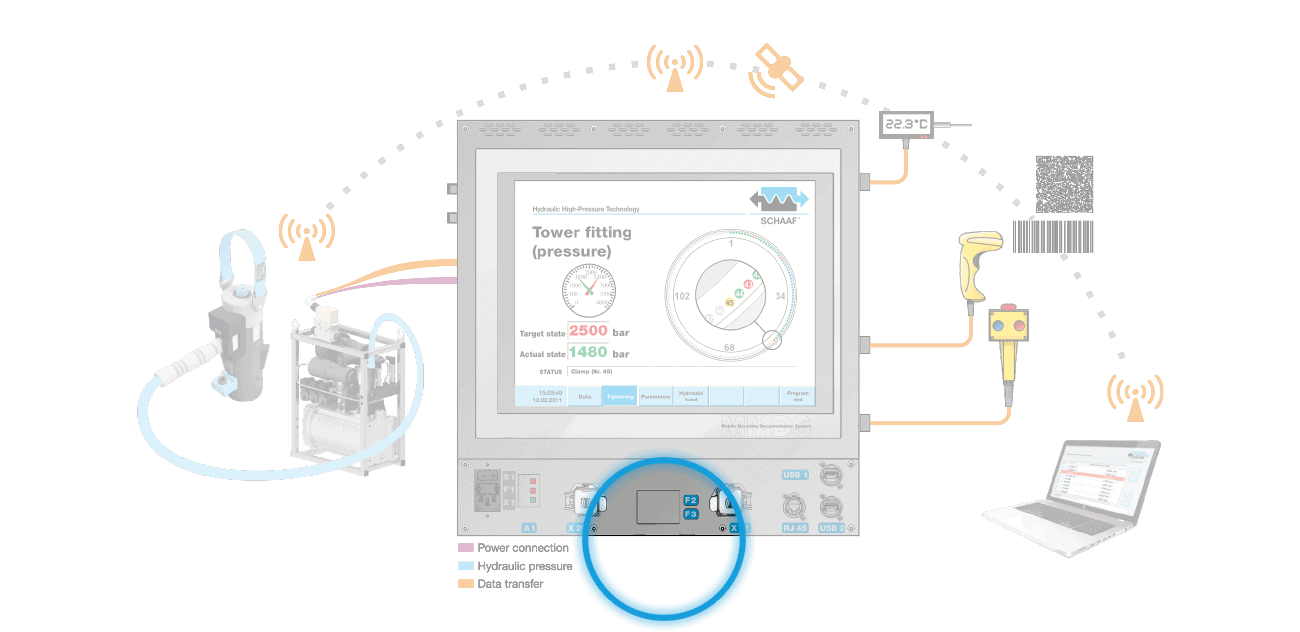

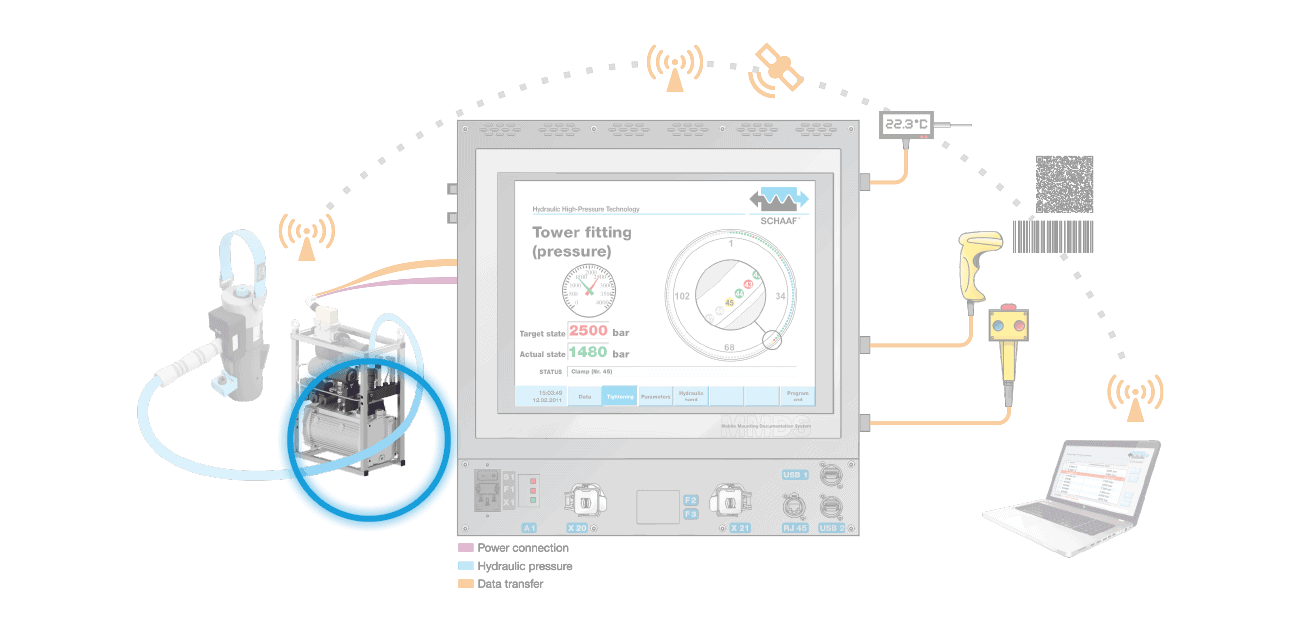

MMDS

Mobile Mounting Documentation System – Full data recording of residual bolt load, bolt elongation and flange compression

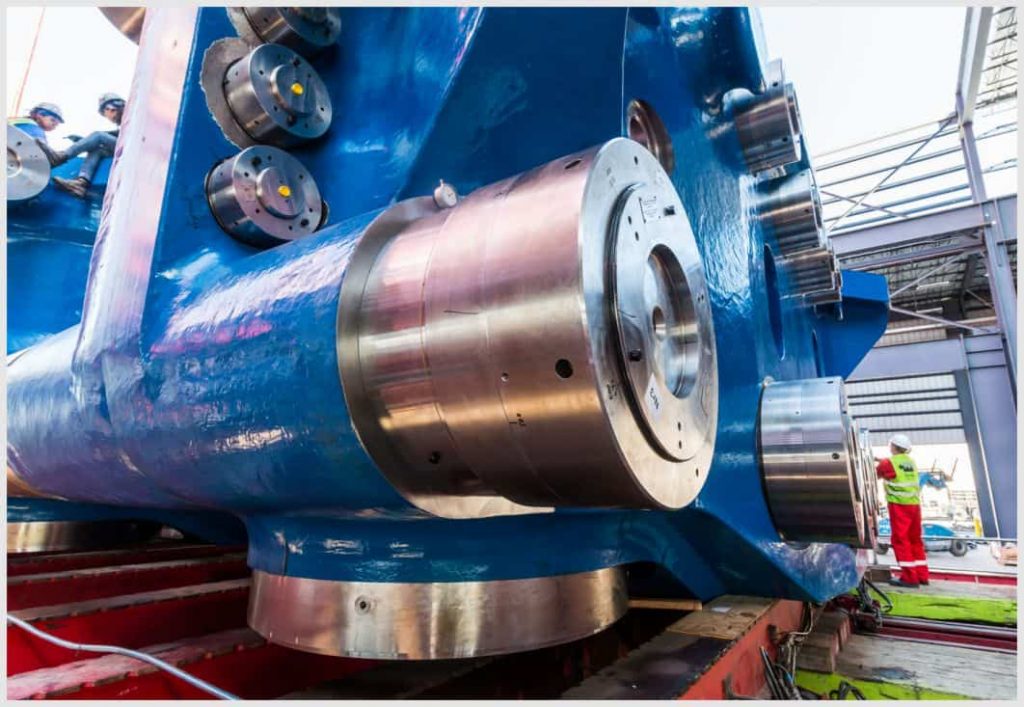

SCHAAF Bolt Tensioner,

2,500 bar working pressure with integrated wireless measuring functions.

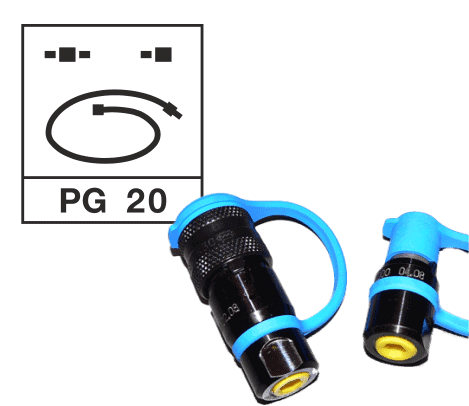

Industrial connector to MMDS.

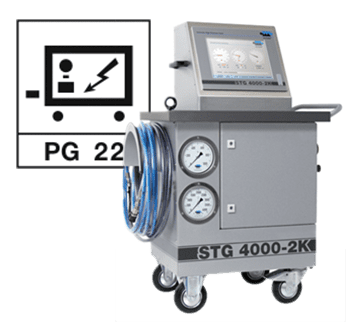

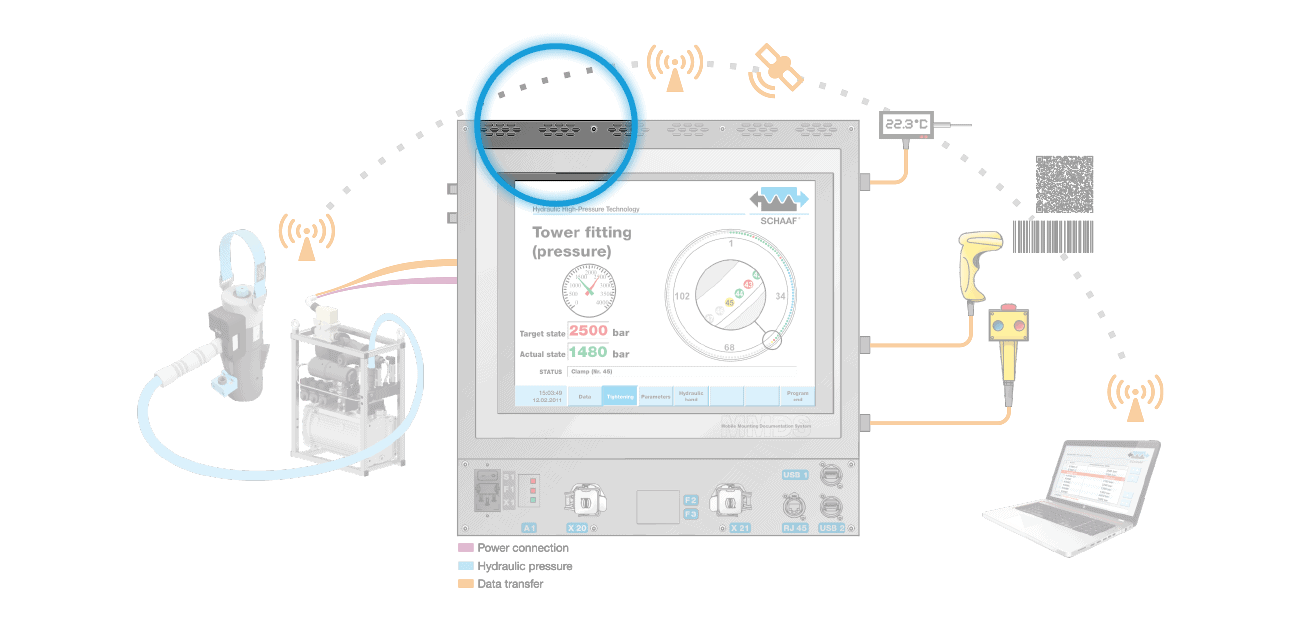

Basic MMDS

with TFT Touch screen and IP65.

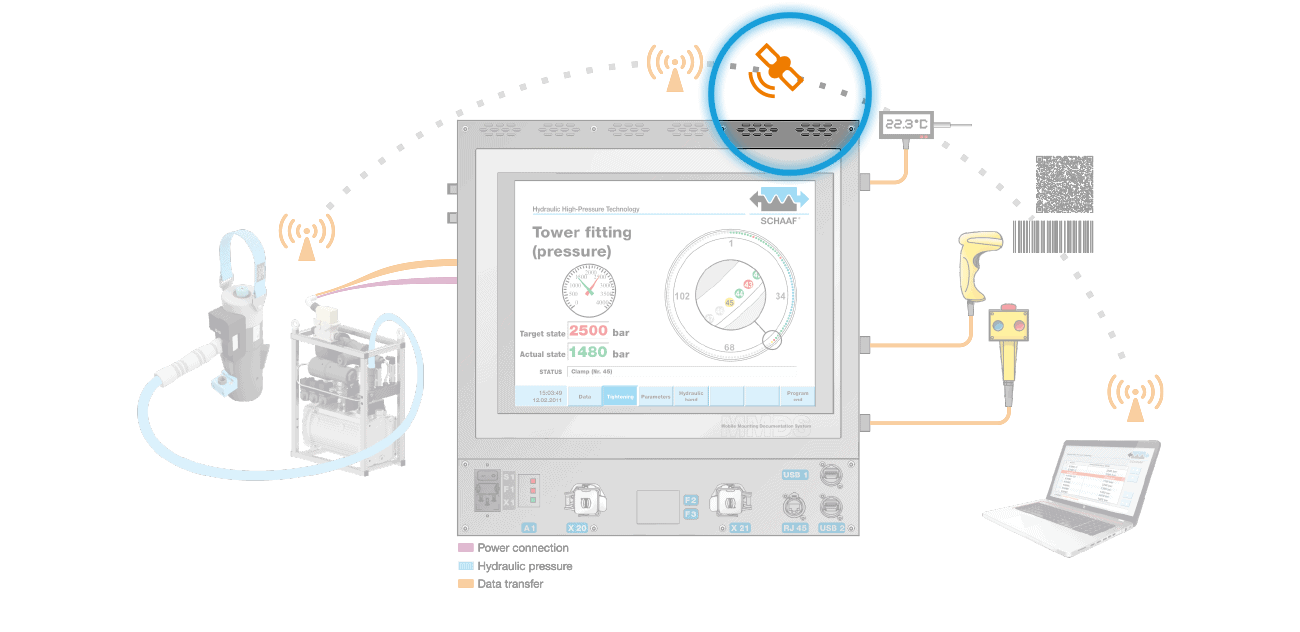

GPS receiver

for global tracking (Option)

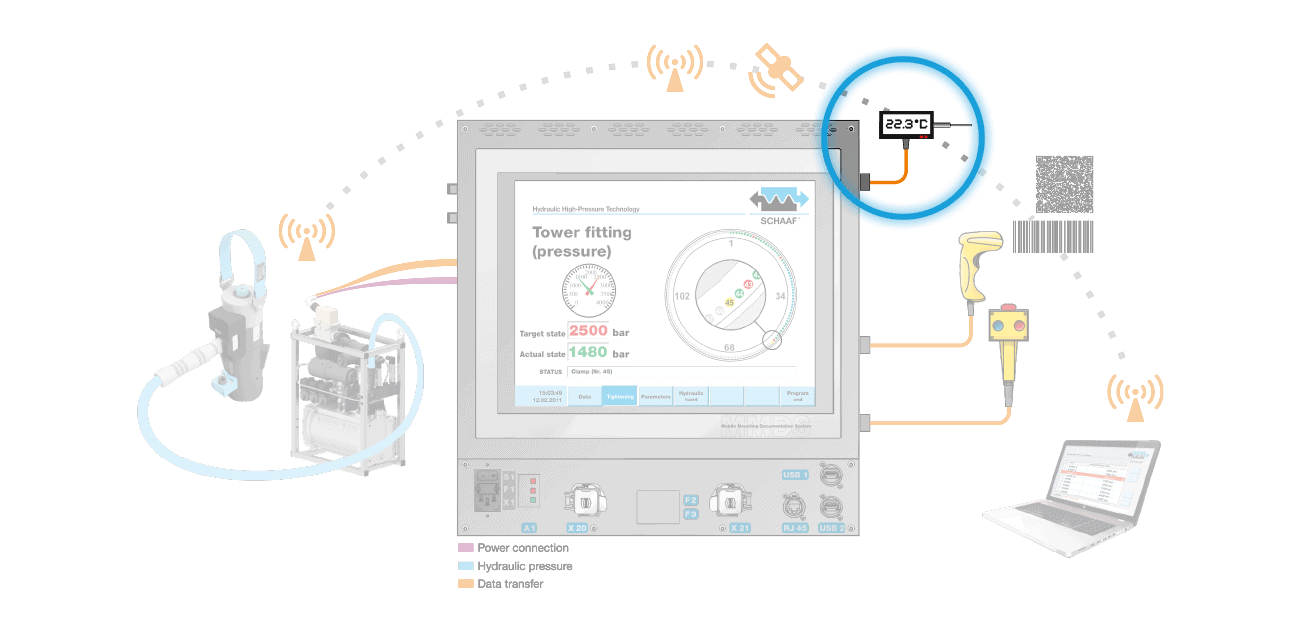

Temperature sensor.

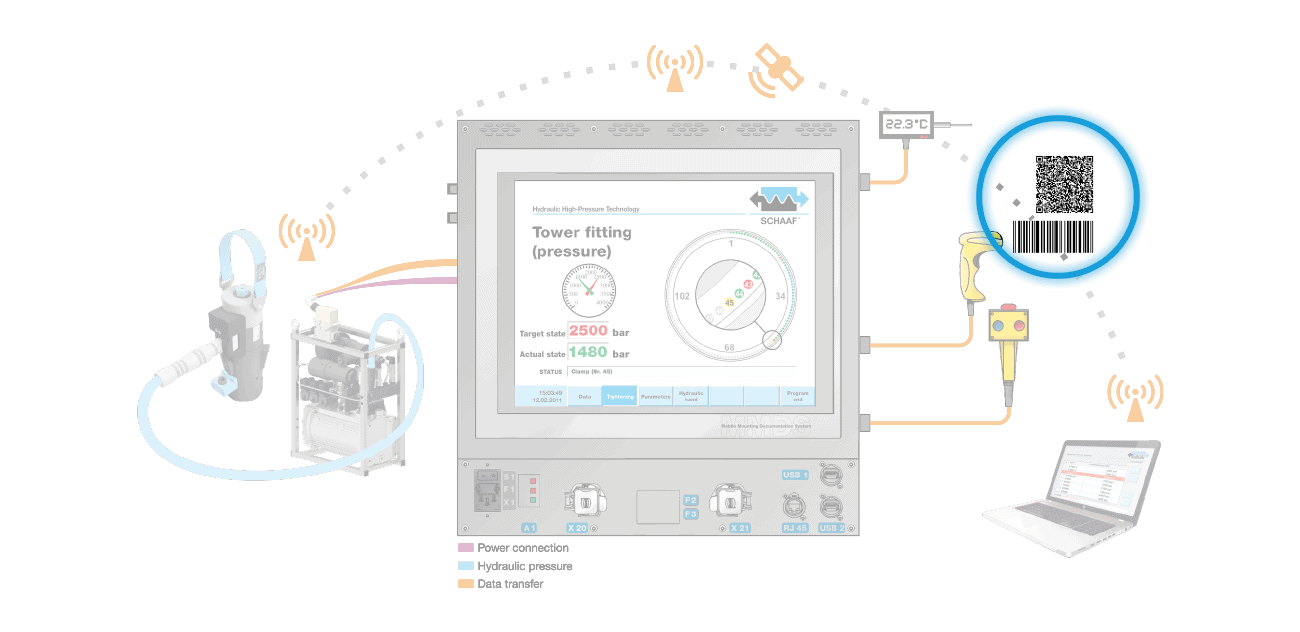

Scanner

Barcode / QR

for data acquisition (Application/ Tool).

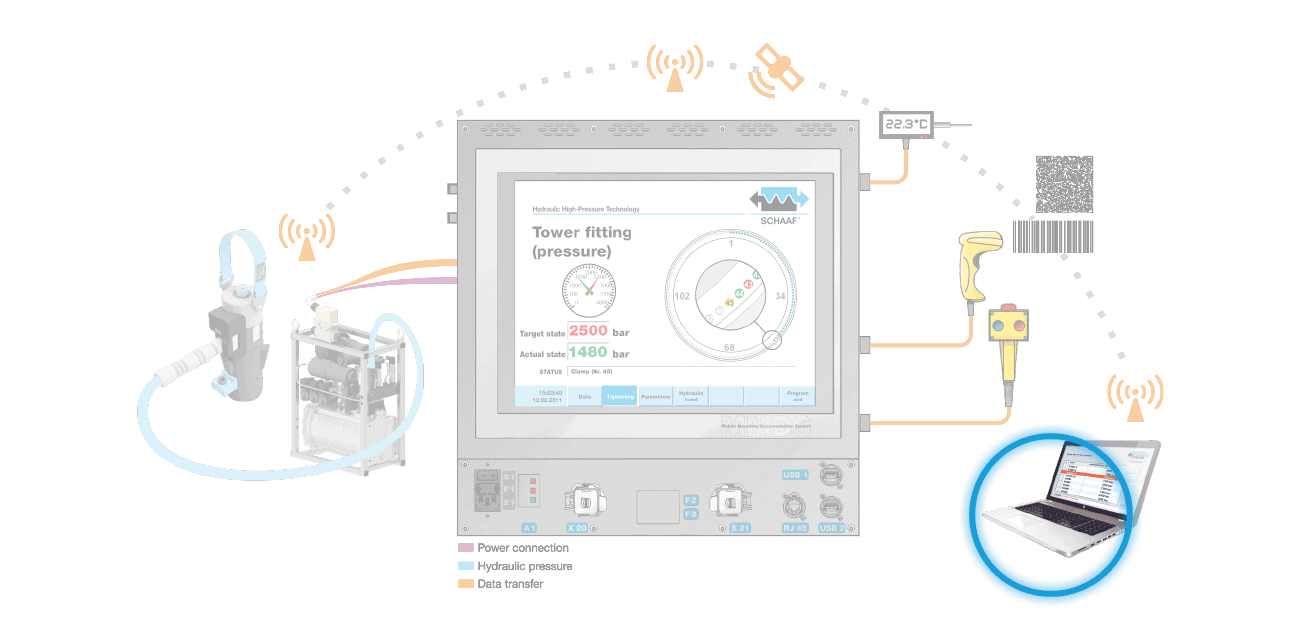

PC / Laptop interface

for data storage and processing via WLAN.

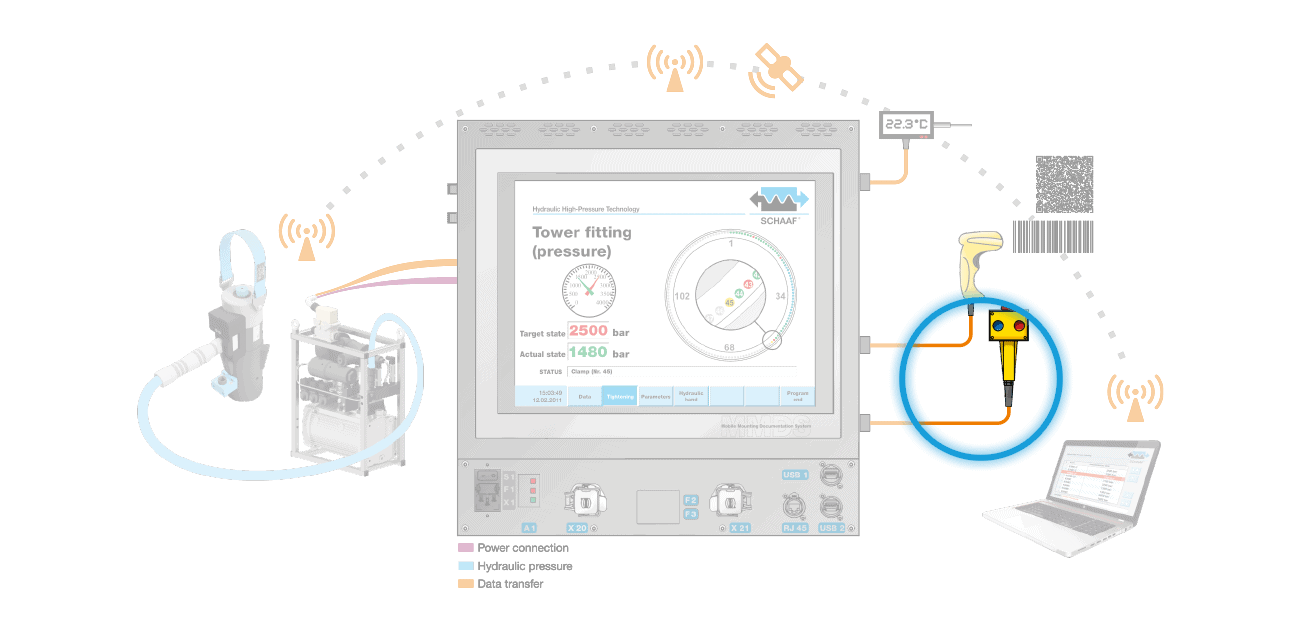

Remote control

for pump unit.

Grid Power Supply:

230V – 50Hz orcustomized.

Stable, mobile casing.

Optionally:

· Tool Management System (TMS)

· TSI Tool Service Indicator (TSI)

· Global Tracking (GT)

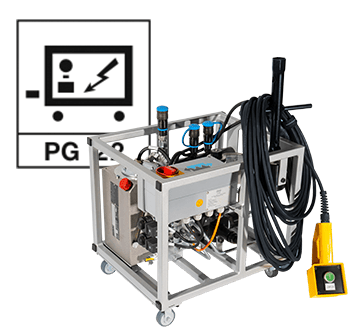

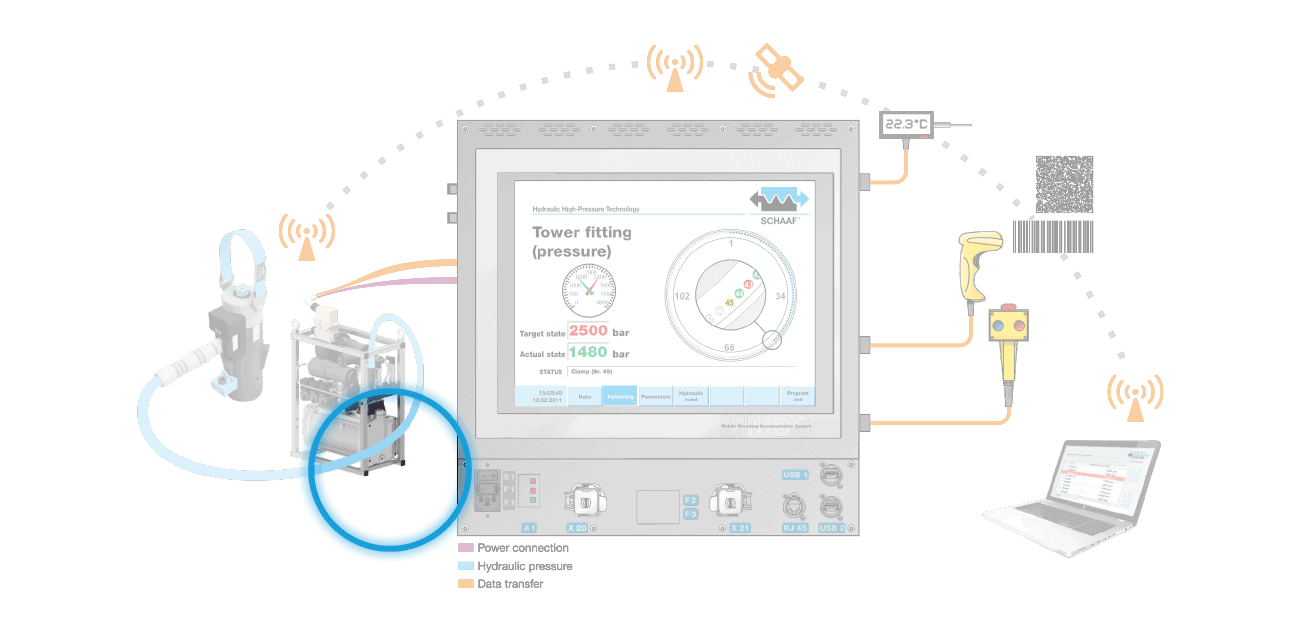

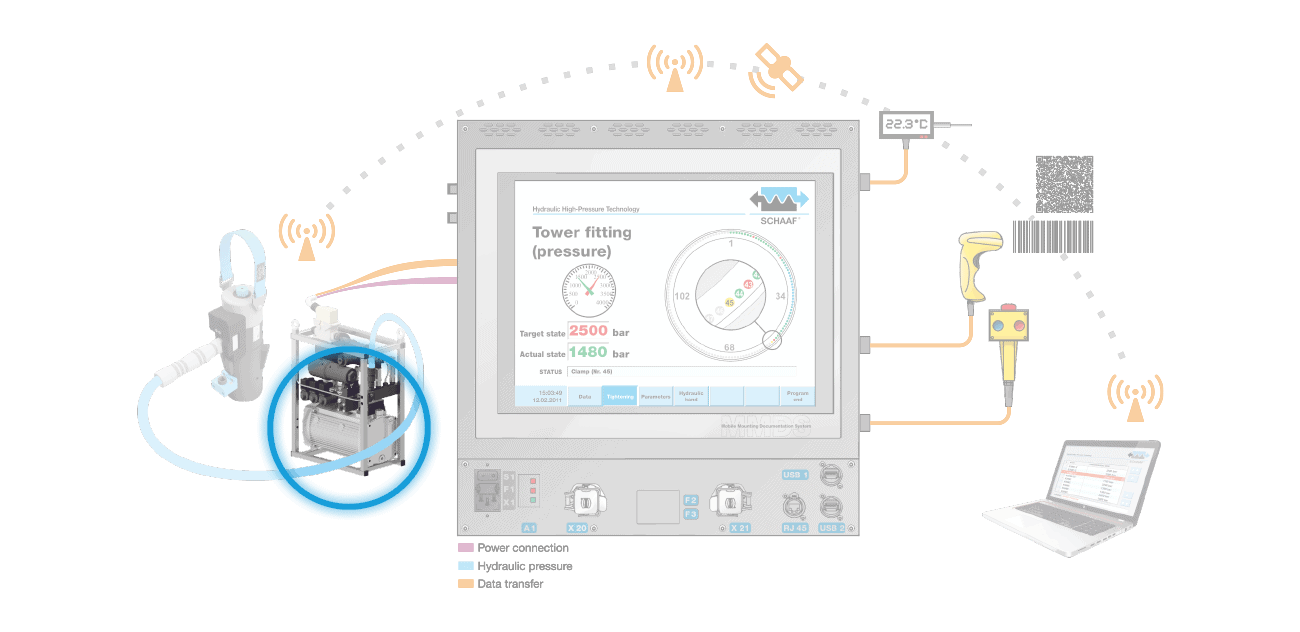

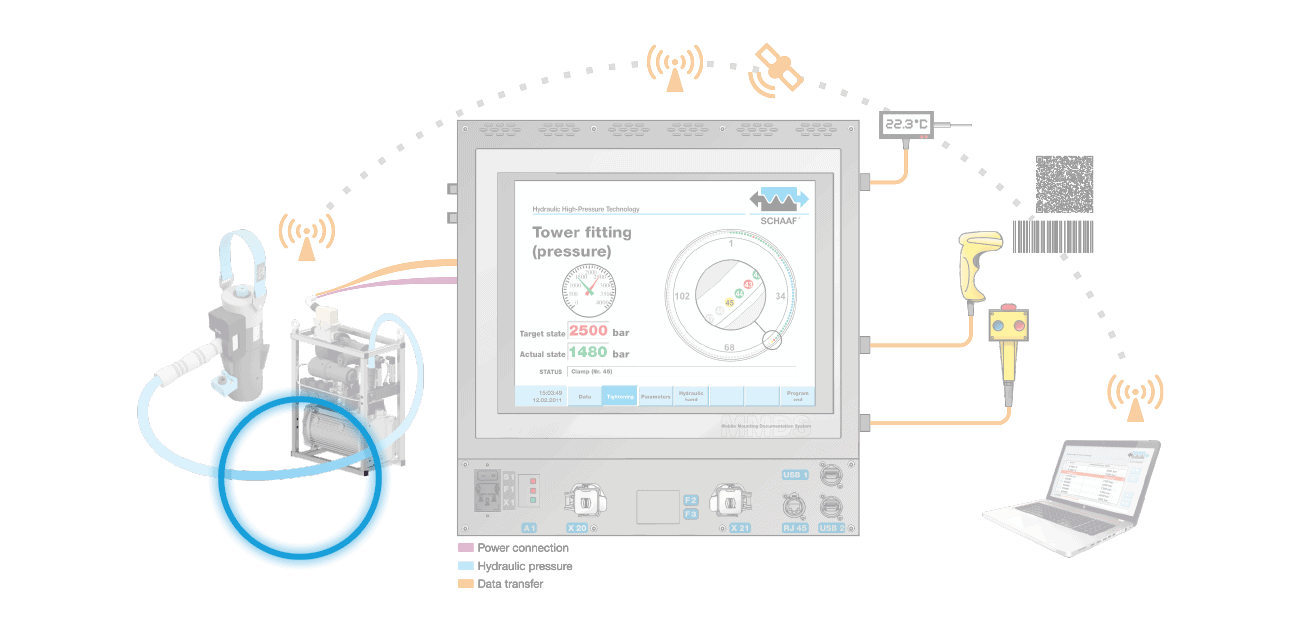

Electric hydraulic pump unit

(air-driven or handlever pump are also possible) with 2,500 bar pressure.

Internal redundant pressure transducers.

Heater / Cooler

High-pressure hose

with coupling system for pressure up to 2,500 bar.

Advantages

- 100% documented quality of bolt connections

- Elongation and compression data can berecorded, displayed, memorized, printed and comprised with the integrated computer

- Increased work safety thanks to frequent pressure and elongation characteristic monitoring

- Simple, clear and comfortable user interface

- Data output on customer quality assurance sheets

- Almost unlimited capability for archiving of tightening procedures

- Tensioning programs and reports can be transferred via USB or LAN-Access

- Long service lifetime and user-friendly maintenance intervals

- Self-monitoring of the MMDS

- Can be operated in line current or battery mode

- Can be used with any kind of pump

- Transportable aluminium case with handle bars

All high-pressure units

Mounting Documentation System for controlling and monitoring the axial hydraulic tightening process of bolts.

Electro-hydraulic two-circuit high-pressure automatic control system for fully automatic pressing of hubs onto shafts and separating

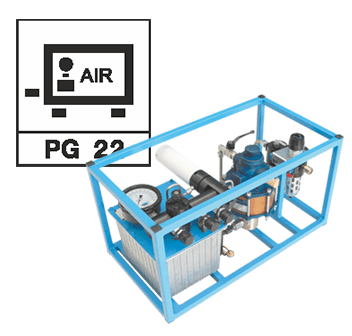

Ready-to-use air-hydraulic pump up to 2,500 and 4,000 bar hydraulic pressure

Versions

- Colour or B+W printer

- Radio-operated remote controller with display

- LAN/W-LAN/USB interface

- Remote access for remote maintenance

- TMS interface (Tool Management System)

- TSI interface (Tool Service Indicator)

- Radio-operated sensors

- Sensors integrated in the bolt tensioners or supplied

- separately

- Central specification of bolting data via SAP interface, database, USB interface or copy and paste

- 1-3K design type for separate control of multiple independent pressure circuits

- Rotation angle and torque control for bolt tensioners with automated motorised re-tightening function

- Optional colour coding of the used equipment

Areas of Application

- Generating a bolt pre-tensioning force for which 100% operational sequencing, safety and data logging are required.

- Engine-building: Main bearing, connecting rod bearing, cylinder head

- Power plants: e.g. Turbines, compressors

- Ring gear bolt connections: e.g. wind power plants

- Tower fittings: e.g. crane construction

- General mechanical engineering

Quality Assurance

All MMDS are checked for 100 % process security. During order handling, they are accompanied by ongoing quality assurance measures and supplied with extensive documentation.

Services

RELATED ACCESSORIES

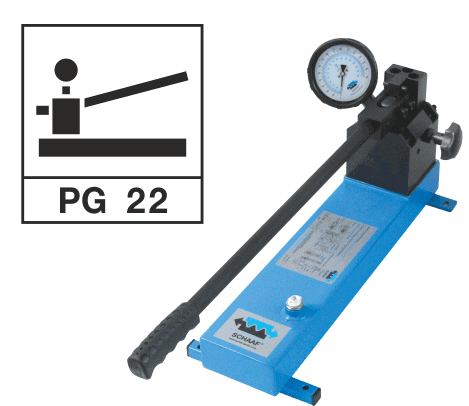

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.