Joining elements

Development and manufacturing of high-pressure hydraulic technology up to 4000 bar

Advantages of SCHAAF products with 4,000 bar – Safety Engineering

The SCHAAF product palette show a large number of technical innovations. They have advantages in the following areas:Safety advantages

- Due to an integrated stroke limiting valve, any overstroke is impossible even in the case of an intentional operating error. This prevents the seals from destruction.

- The SCHAAF Bolt Tensioner automatically returns to zero position after each clamping procedure, consequently ensuring quick operation with the least effort for the user.

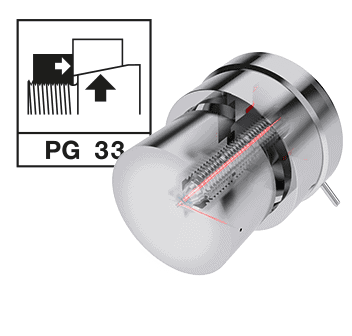

- As an additional control, the stroke is displayed on an easily visible and simple stroke indicator.

- Integrated mounting aids with years of successful use allow straightforward operating of SCHAAF products and help their application. Malfunction is almost impossible and time saving guaranteed.

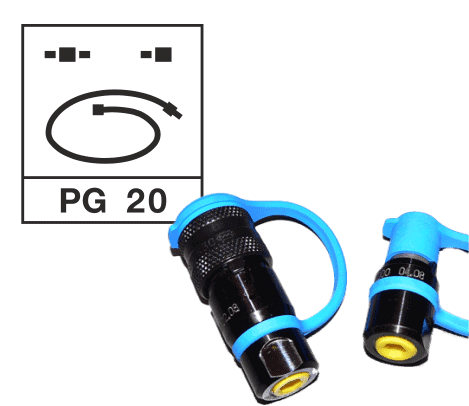

- Because of coordinated SCHAAF accessories like couplings and nipples connections, the possibility of hazard caused by the inappropriate connections of high pressure connections is reduced.

Weight advantages

- All SCHAAF Bolt Tensioners offer easy handling, high-performing ergonomic principles for staff, good accessibility for limited space conditions and high operating speed due to their minimal diameter and height.

- The low weight of the transport boxes means lower transport costs.

- The handy lightweight Bolt Tensioners are particularly advantageous for overhead assembly.

Modified Structural Design advantages

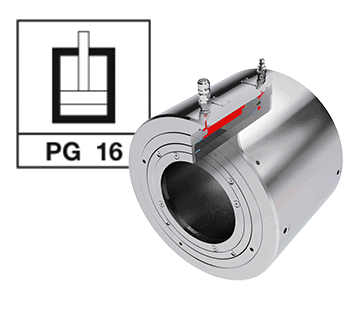

- Through the large window in the support sleeve which is rotatable, it is possible to tighten the nut by hand without further tools. This quick method result in saved assembly time.

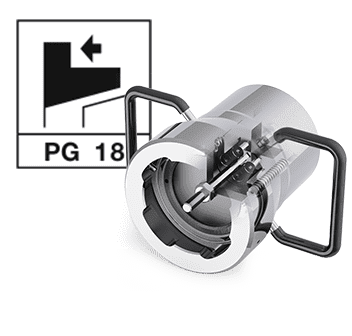

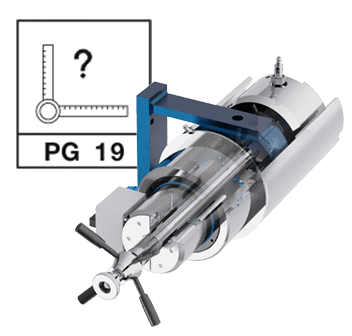

- High precision of the bolt connection and a secure check of the nuts support on the flange resp. is enabled by using a feeler gauge through the inspection aperture in the support sleeve so that possible galling of the nut on the thread is quickly and precisely recognized and, if possible, avoided.

- A cover plate serves to protect the interior from dirt.

- Operating is quick since there is no need of a separate tension nut or a special tool respectively. The complete Bolt Tensioner consists of one unit only.

- Easy registration of the thread beginning, because of the large centering recess, which is useful when mounting the Tensioner.

Size advantages

- The minimal dimensions of the Bolt Tensioners enable small-dimensioned transport boxes.

- Good accessibility for inconvenient operation points is guaranteed.

- New designs can use smaller dimensions of the bolt connection by improved course of the strain lines.

- Smaller dimensions of the tensioned components since the tensioning force is applied on improved course of the effective line.

Operational Safety

- No unnecessary overhauls are required since the Bolt Tensioner can be controlled by eye-sight.

- Set-up errors are out of the question since thread size, pressure and preload force are clearly denoted on the Bolt Tensioner. Because of this, damage to components can be avoided.

- On request, endurance test samples can be carried out to find the life time and maximum possible load frequency for guaranteed safety.

Previous slide

Next slide

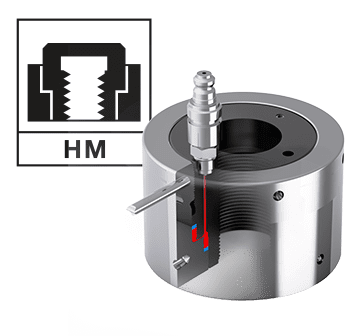

Bolt tensioning techniques

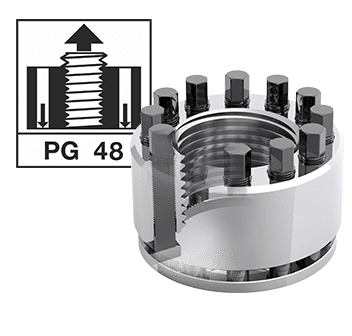

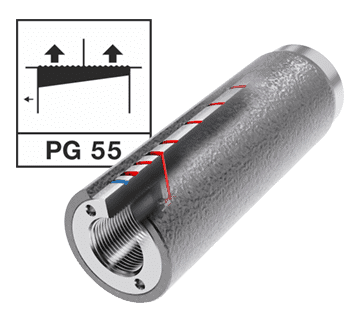

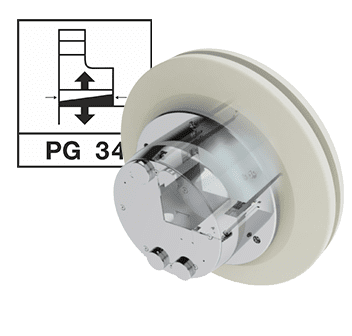

Shafts and axles connections

Versions

Customized and standardized mounting devices for hubs on conical or cylindrical shaft seats

Customized and standardized dismounting devices for hubs on conical or cylindrical shaft seats

Clamping Nuts are customized and can be used in systems that require quick clamping features or as overload limiters.

Related Accessories

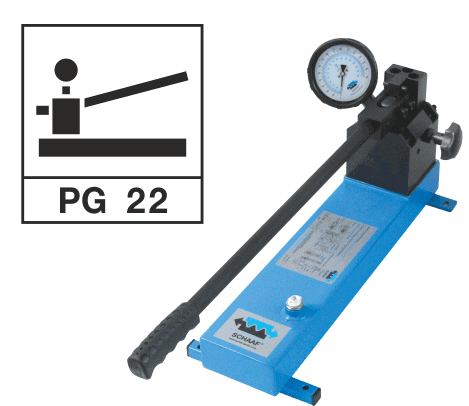

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.