OBLM

Online Bolt Load Monitoring

Real-time analysis – Plug and play – Real life experience

OBLM – Accurate long-term bolt load monitoring and safety failure warnings.

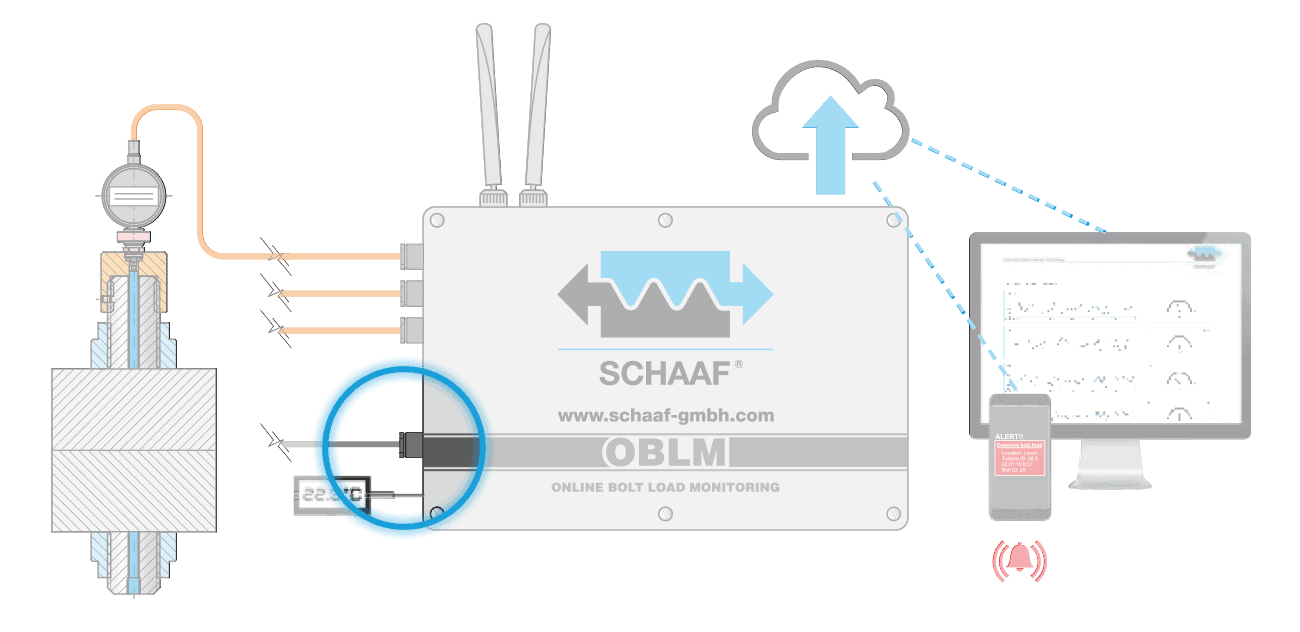

Online Bolt Load Monitoring

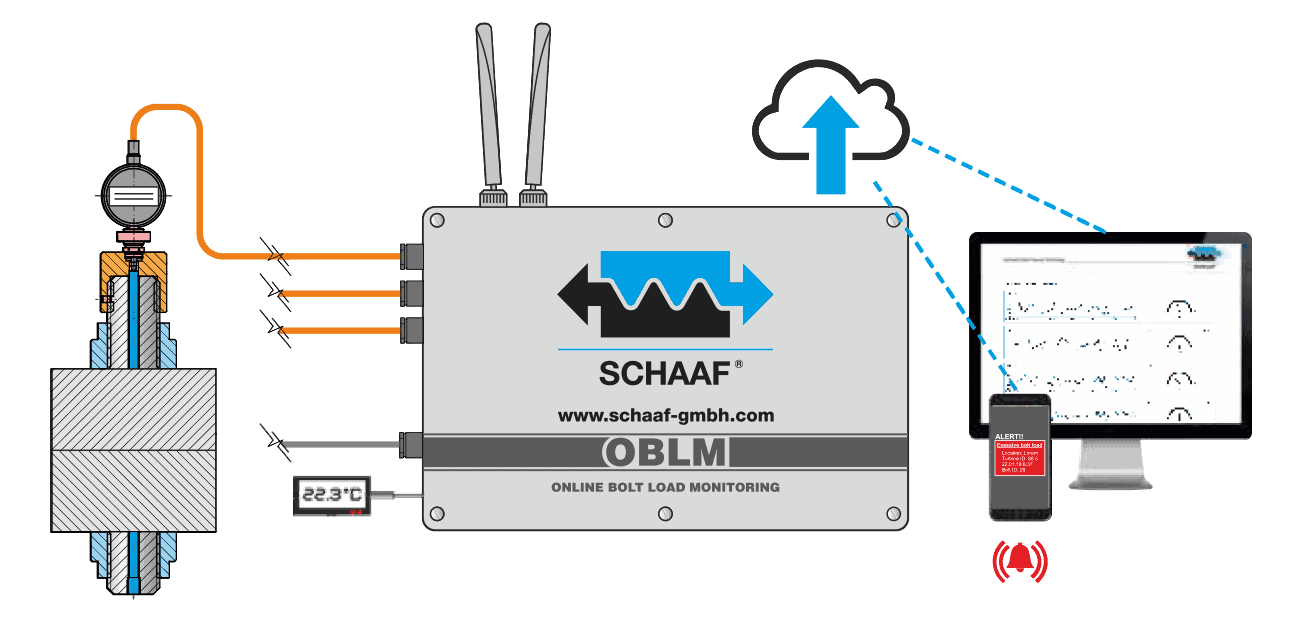

Measurement with stressless rod.

Possible monitoring and capturing of temperatures,

wind-forces and wind-directions or other relevant data.

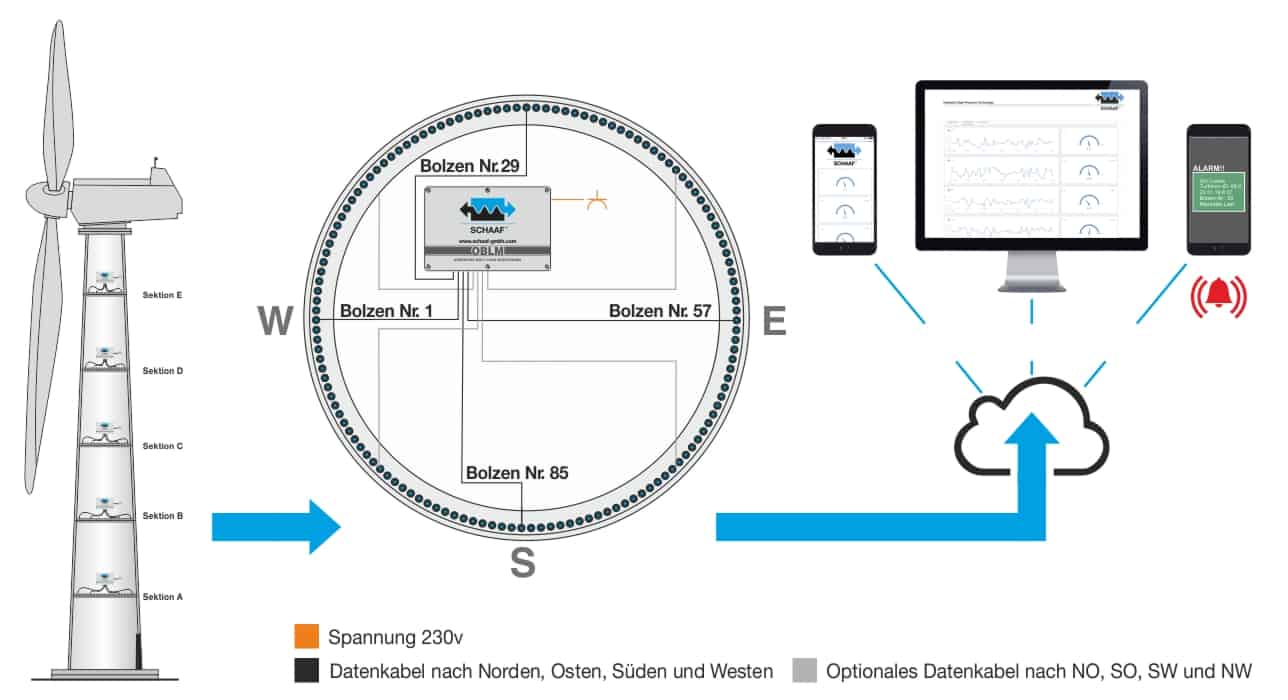

Grid Power Supply:230V – 50Hz orcustomized.

Up to 8 highly precise sensors per OBLM possible,

that are able to measure even the smallest deviations in clamping force.

Integrated and globally independent GSM-Module,

made to relieve company networks.

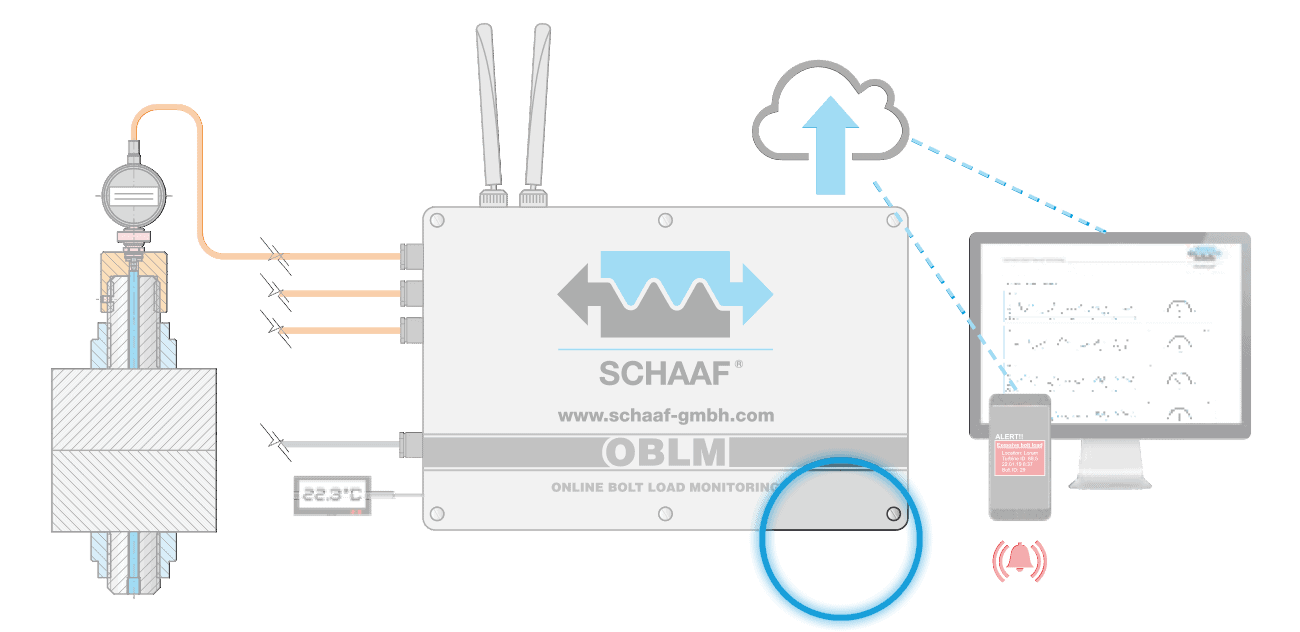

Compact design,

enabling minimal installation effort.

IP67 protected case.

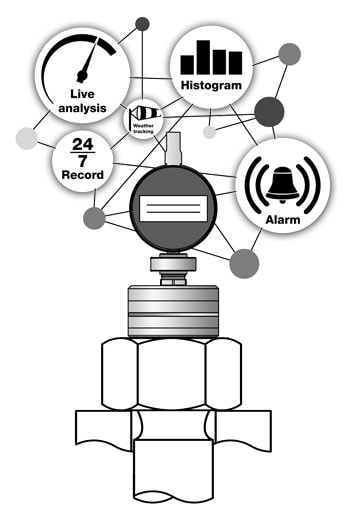

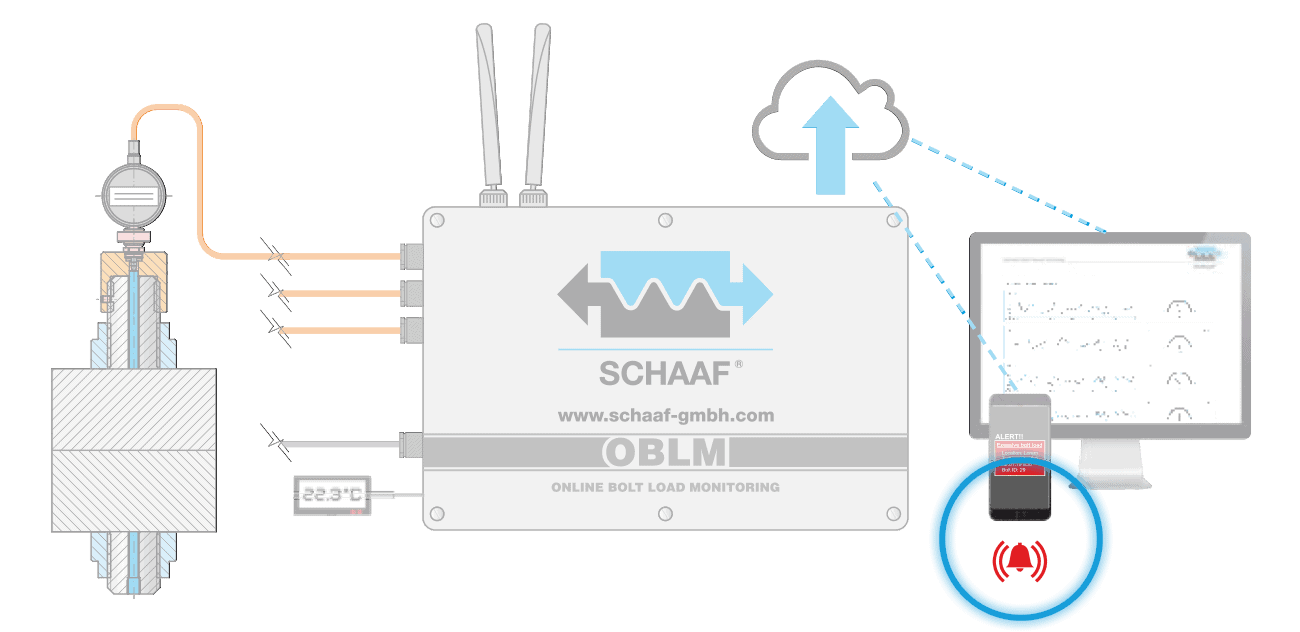

Alarm function

for breaching of threshold values.

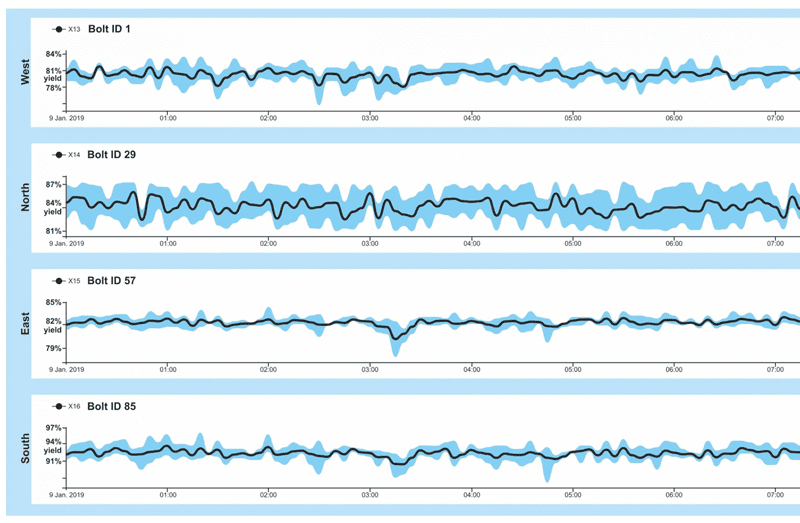

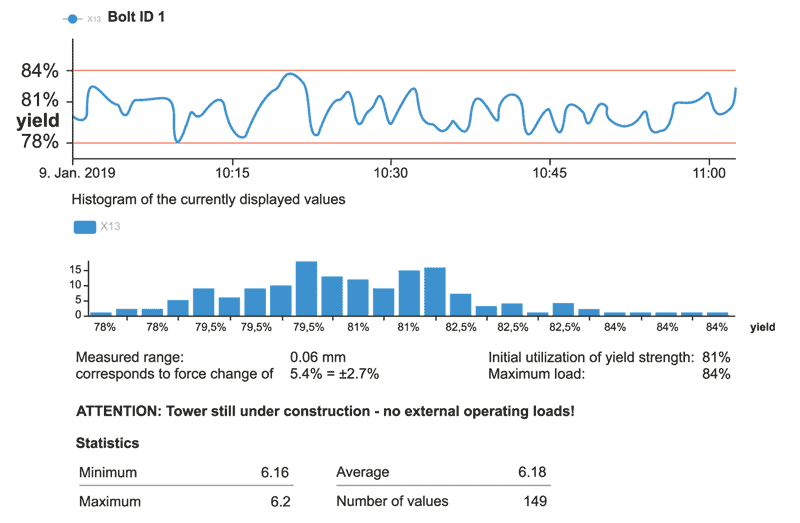

Precies real-time analysis or long-term evaluation of each sensor.

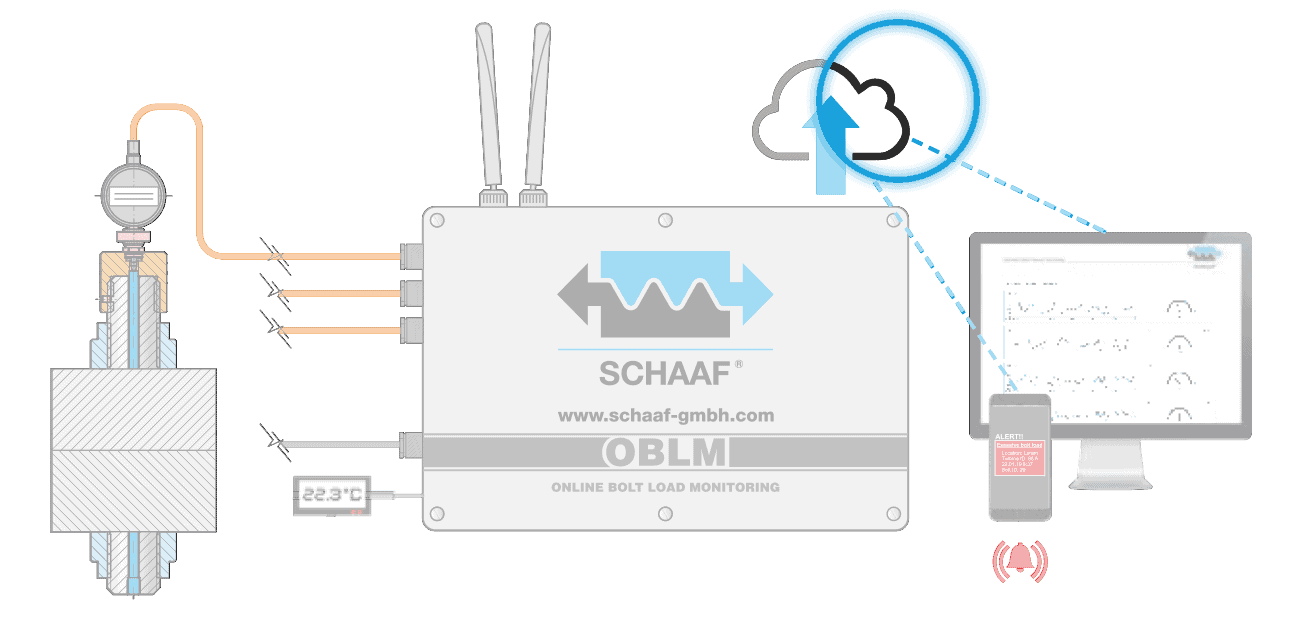

Transmission of min, max, average load data and all other valuable parameters

such as date, time, etc. to the cloud server up to 1x per second.

The smart IoT solution

“The question of “how a system is affected under real conditions” has been asked too many times. Until now, the condition of operating machineries could often only be determined inadequately. But: Online Bolt Load Monitoring (OBLM) is a comprehensive solution for measuring real-time status changes of systems – under full operating load. Monitoring and transmission technology, hardware, software, sensors, cloud, measurement data analysis – OBLM combines all these components into an optimally harmonised IoT solution. The OBLM system not only transfers information in real time, but also supports complex data analysis and evaluation. The newly gained insights help to save resources and recognise undesirable conditions at an early stage.

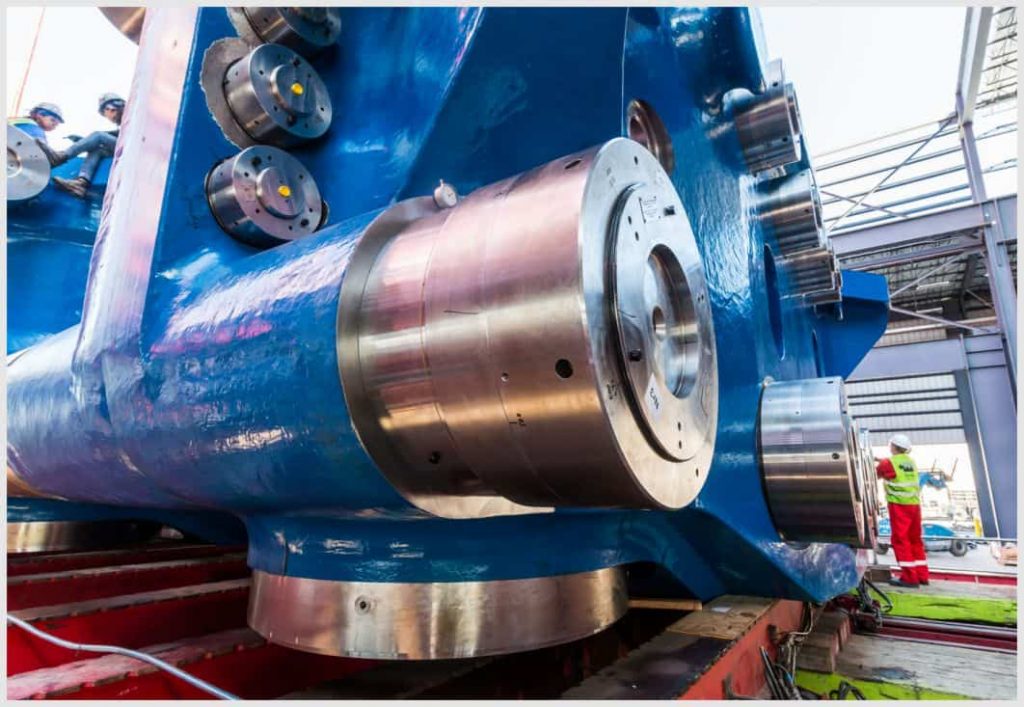

The OBLM enables unprecedented real-time analysis of the tension of bolted joints during machine operation. Thanks to many years of experience, SCHAAF has a technology that allows it to monitor and analyse stresses occurring in the bolt even under full operating load. Using sophisticated real-time analysis tools and high-precision measuring sensors, even the smallest changes in bolt length are recorded and the resulting bolt tension calculated. This makes it possible to analyse and understand your machine in the various operating states (start-up, normal and exceptional operation, standby/idle time, heating up/cooling down).

Scope of service

- Data collection up to 16 sensors

- Real-time transmission of data, via LAN and GSM (worldwide)

- Storage of measured data in the event of communication failure

- Live data, platform independent

- Sampling of measured data 1x/second (adjustable). The analysis occurs before transmission to the cloud

- Transmission of data 1x/minute, with the following values being transmitted: maximum, average and minimum

- Defined threshold values that transmit automated messages upon exceedance

Versions

All conceivable special designs are possible. Please let us know your requirements.

Areas of Application

SCHAAF OBLM is the optimal solution, where constant monitoring can prevent damages or injuries. Additional estimated bolt loads during design stage can be proved if correct. Especially for connections with permanent vibrations, weather related changes or load changes, for example wind turbines, bridge construction, cranes, electric generators and motors.

Quality Assurance

All OBLM are checked for 100 % process security. During order handling, they are accompanied by ongoing quality assurance measures and supplied with extensive documentation.

Services

SCHAAF OBLM are user-friendly, reliable, and manufactured in accordance with the highest level of technical know-how. Our highly-motivated staff would be pleased to train your personnel, in situ or at our works, in the general handling and operation of the mobile and stationary control unit. In this way, all the process parameters can be entered optimally in order to achieve maximum process monitoring and safety. Of course, the OBLM are supplied ready for operation.