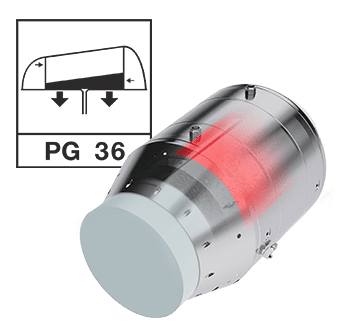

GripLoc special solutions

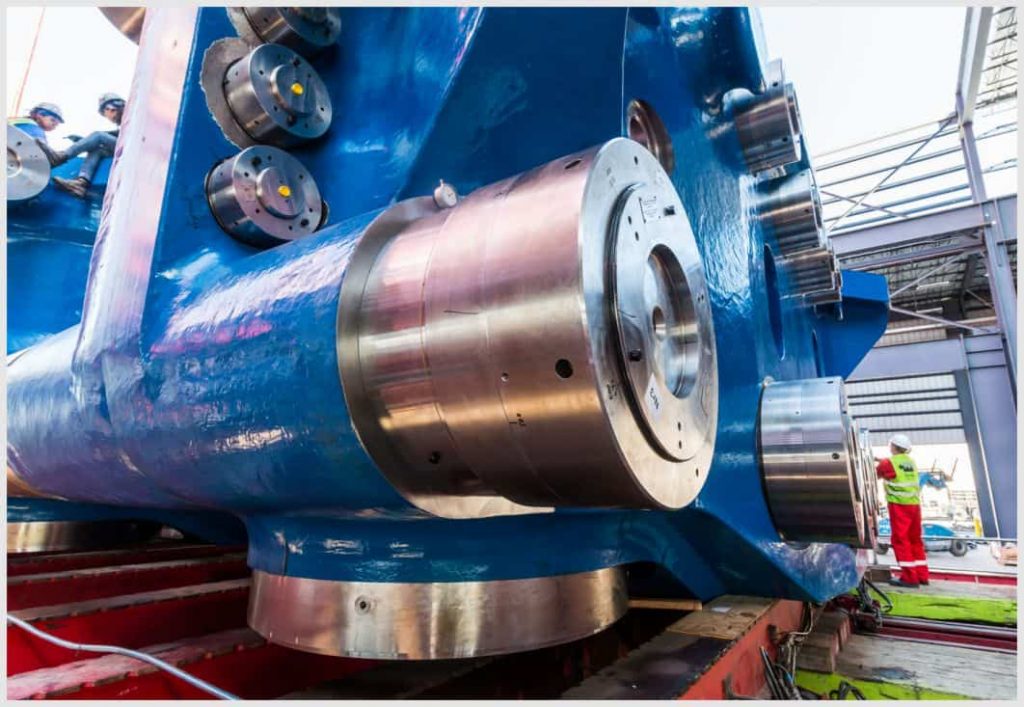

Shaft and axle connection as a special solution for individual areas of application

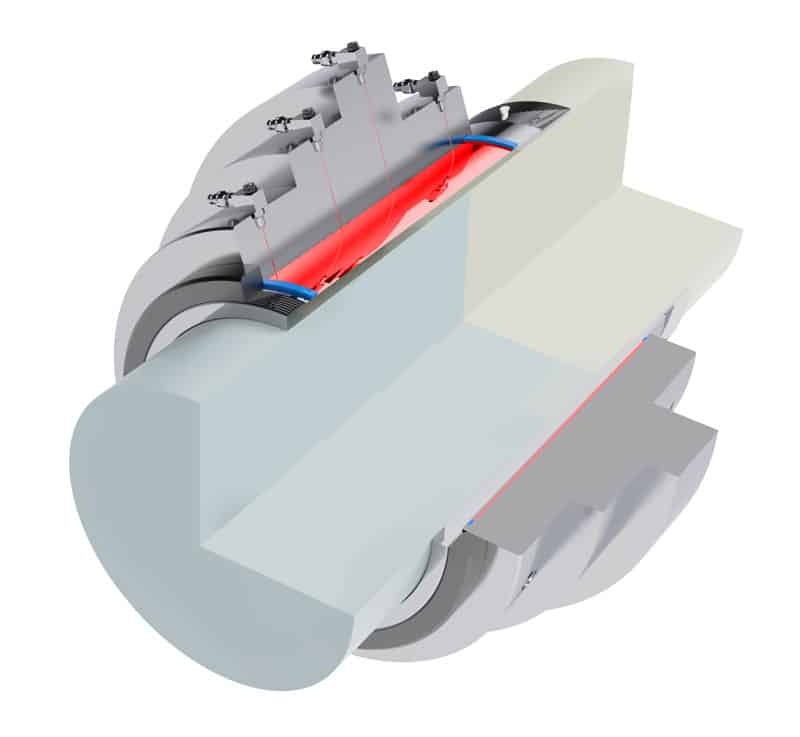

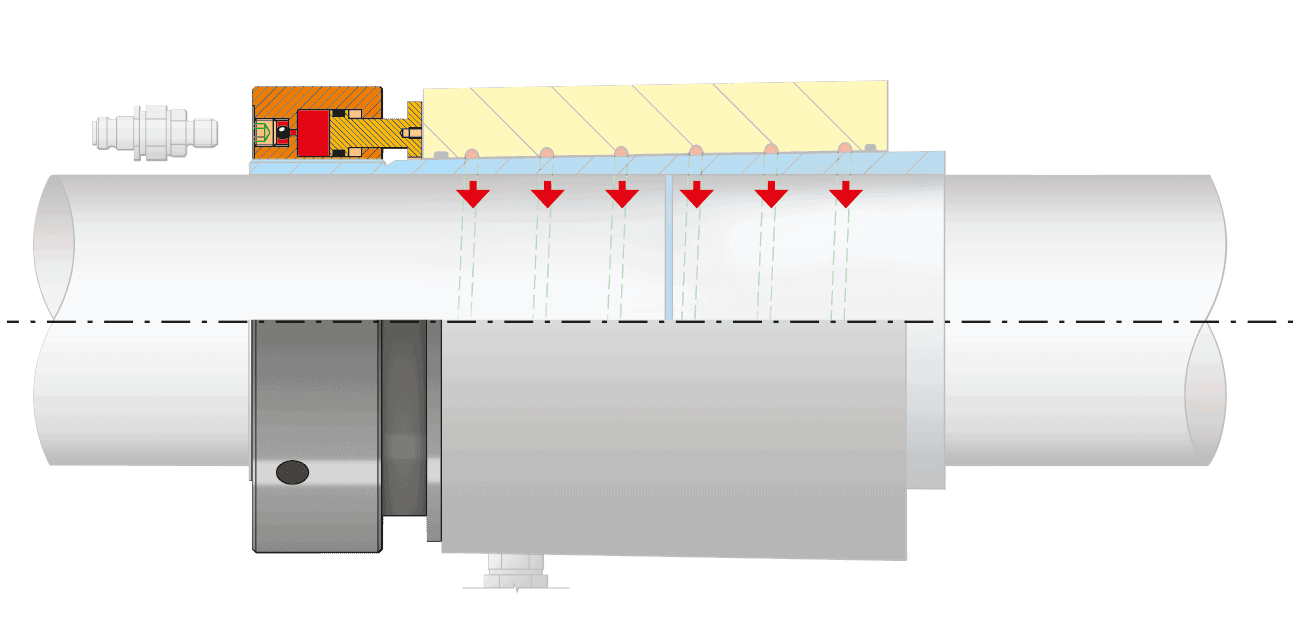

GripLoc creates radial pressure on the two shaft or axle stubs to be connected by radially shrinking a previously hydraulically expanded outer body. GripLoc can be quickly clamped and released.

For every area of application can be found the optimum solution and adapted in type of construction with the help of GripLoc technology.

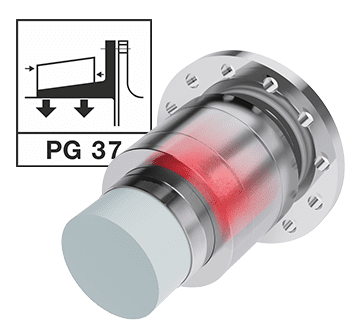

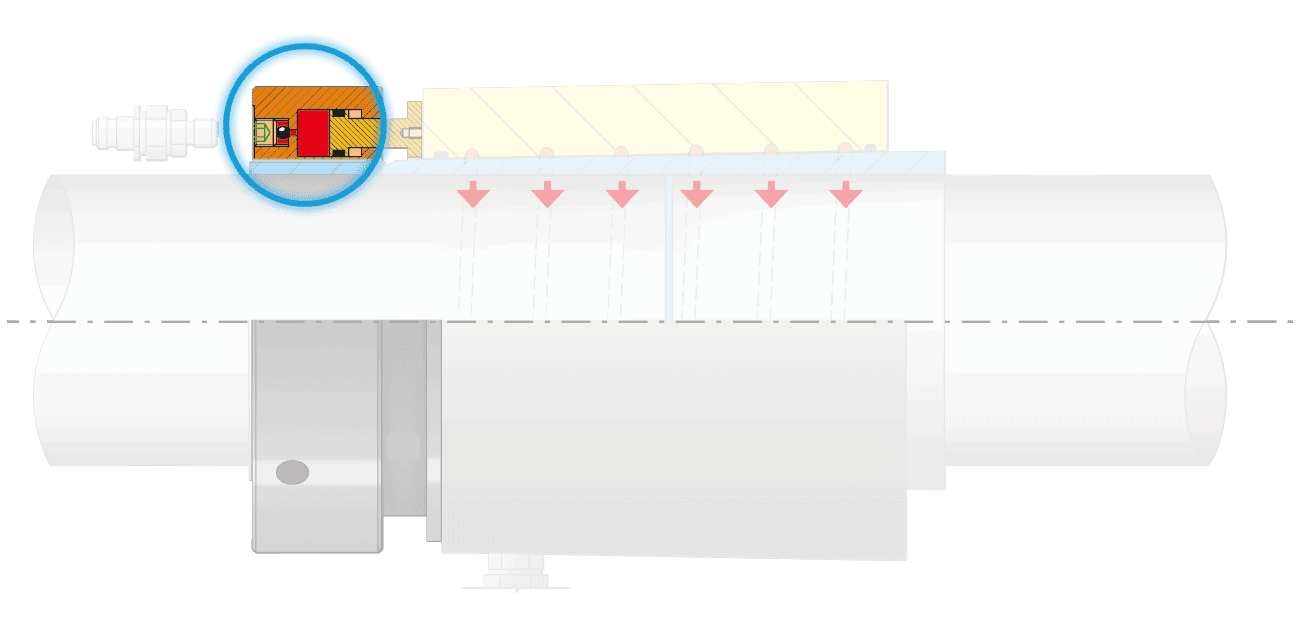

GripLoc PG 38

Permanently installed hydraulic nut

as a push-on unit for the outer cone sleeve.

No additional SafeLoc is needed.

SafeLoc element

is firmly integrated in the hydraulic nut or in the cone sleeve.

Advantages

- Individual design for every area of application

- Patented GripLoc sliding-on procedures for destruction-free interference fit assembling

- GripLoc can be removed simply and quickly even after years of use – again and again wearless

- High torque transmission, completely free from backlash

- Torsionally and flexurally rigid connection even with sudden changes in the rotational speed, torque, or direction of rotation

- Maximum torque transfer even in minimum installation space thanks to SCHAAF friction increase

- Removability is always ensured if replacement of defective Hydraulic Nut seal is ever required

- Time saving on assembly and disassembly

Individual solutions

The various SCHAAF GripLoc characteristics can be freely combined with each other. For example, GripLoc can be designed with a SafeLoc mechanism in a removable hydraulic nut. In this way, an optimal solution can be found for every application.

Versions

- Inner and Outer tapered sleeves made from high tensile strength steel for maximum strength and durability

- Use of corrosion-resistant materials for use in different media

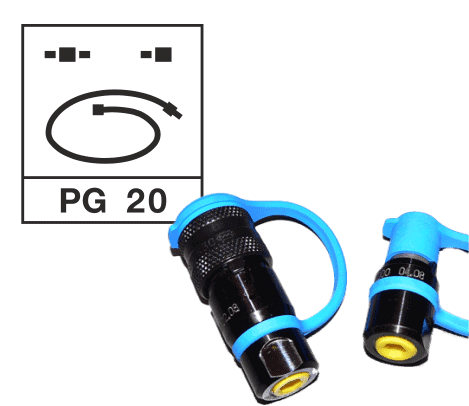

- Combination of GripLoc with a wide variety of mounting tools for optimum design of the assembly process

- Design depending on application with split, removable Hydraulic Nut or permanently installed annular piston.

- Mechanical, axial slide-on by means of torque (MSN) optionally possible

- SafeLoc for safe installation

Areas of Application

SCHAAF GripLoc couplings are the optimum solution wherever high torques (forces) must be transmitted and, at the same time, easy and quick assembly / removal must be ensured. Contact us for optimally dimensioning your shaft and axle connections.

Quality Assurance

All GripLoc are checked for material quality, dimensional accuracy, correct functioning and load-resistance. During order execution, they are subject to continuous quality assurance measures and are supplied together with detailed technical documentation

Services

GripLoc are, of course, supplied packaged, ready for installation and use.

SCHAAF GripLoc couplings are user-friendly, reliable, and manufactured in accordance with the highest level of technical know-how. Our highly motivated staff would be pleased to train your personnel, in situ or at our works, in mounting and dismantling the bolts.

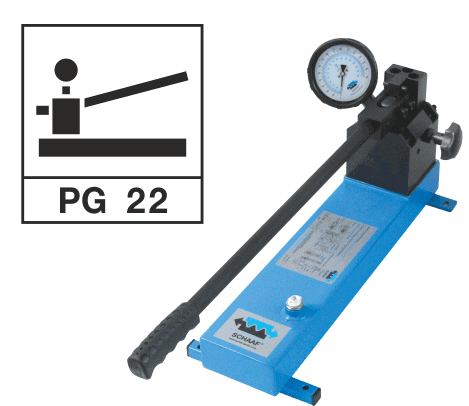

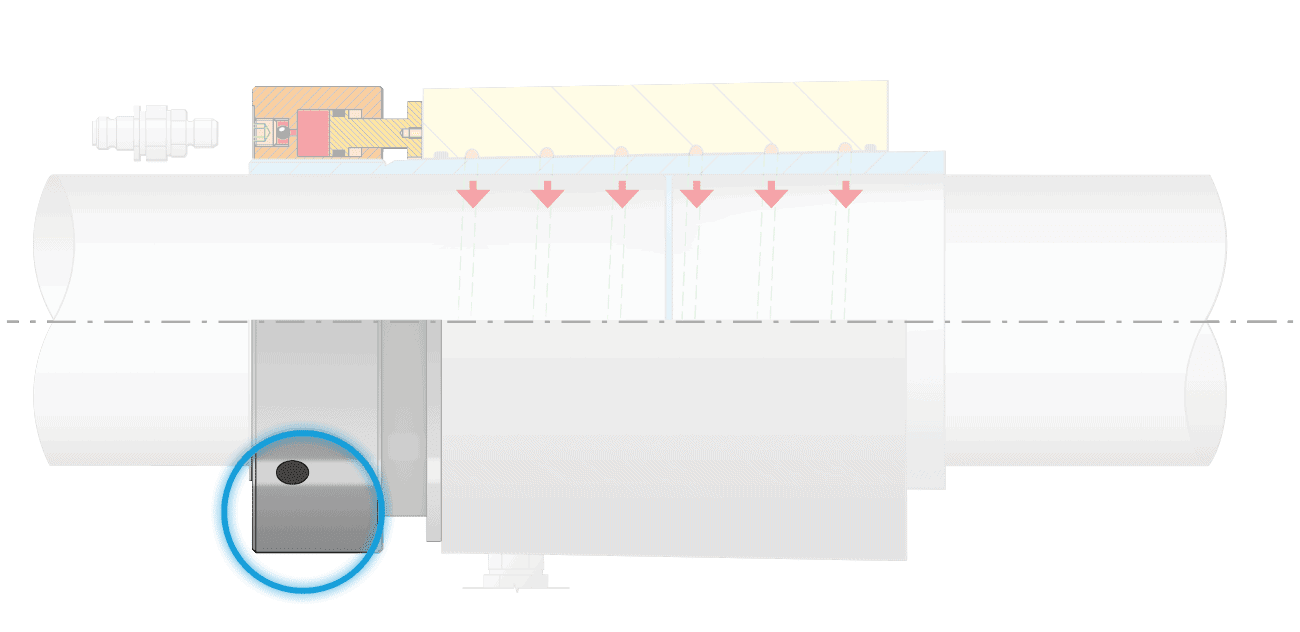

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.