Multiple Stud Nut (MSN)

Axial Bolt Tensioning using torque

Simple way to achieve a torsion-free axial preload force with increased assembly effort. The MSN replaces the standard nut in a bolted connection.

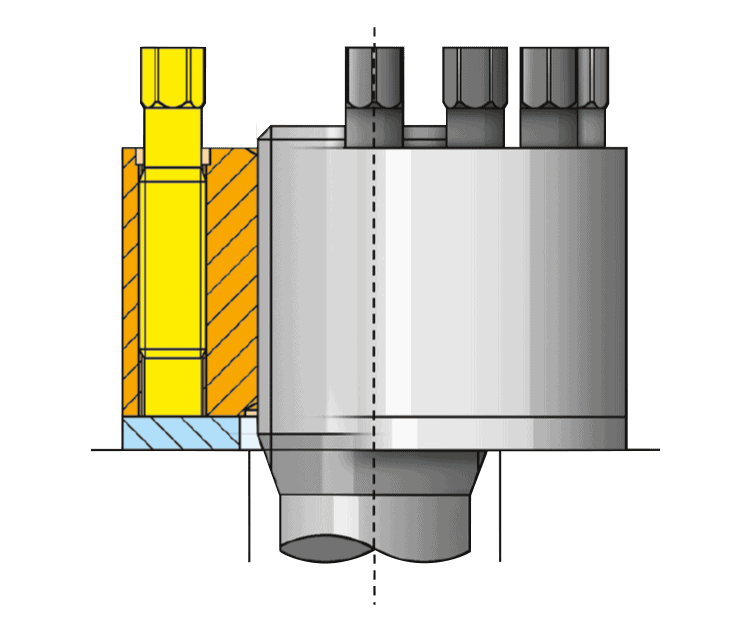

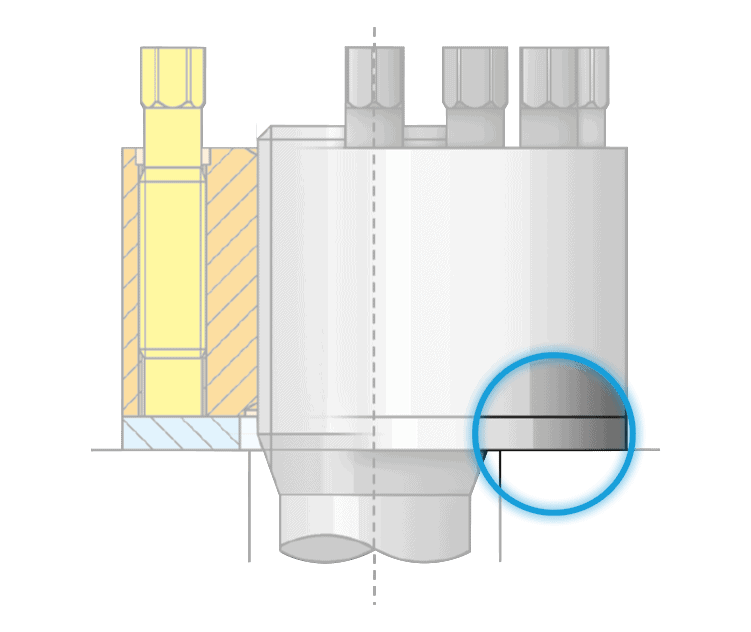

Basic position

The MSN is screwed onto the bolt being tightened until lying at the clamping disc. The Jackbolts are integrated into the nut body and ready for pretensioning generation.

Bolt to tension

Jackbolt

Nut body

Disc

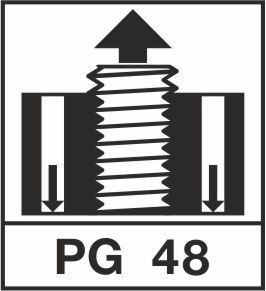

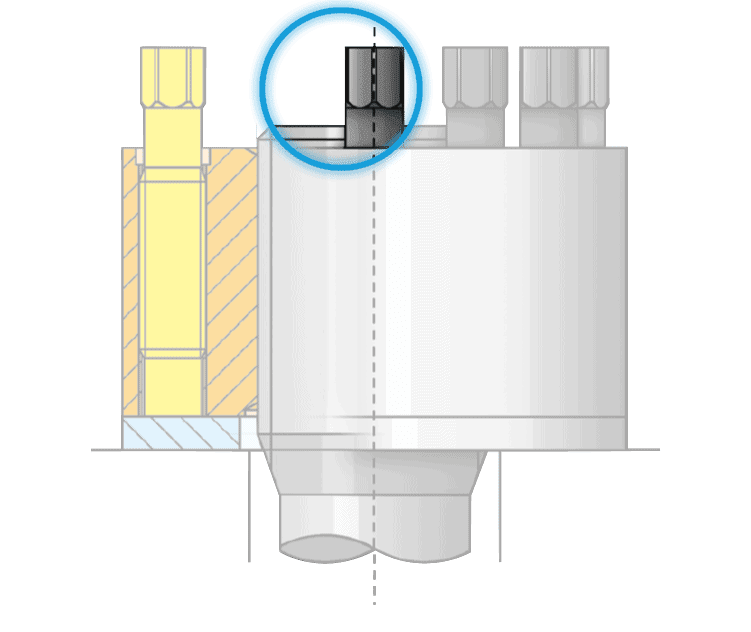

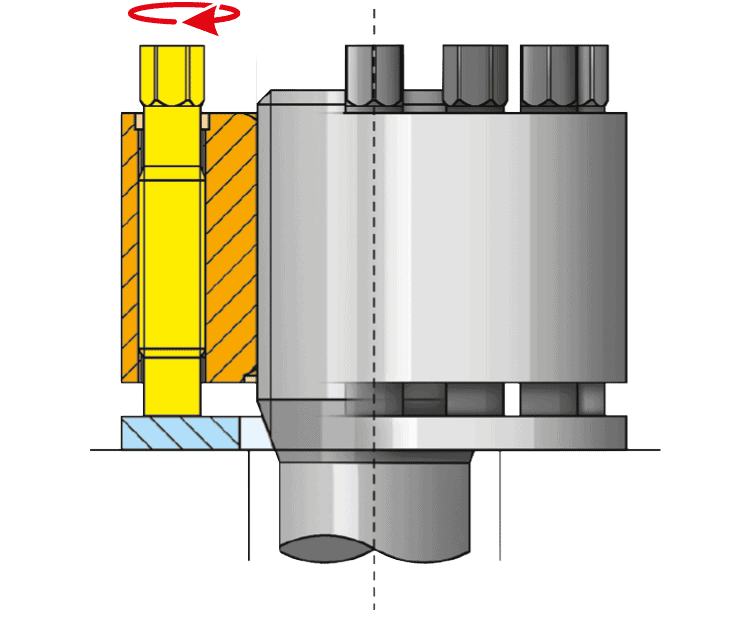

Elongation and compression

Due to the stepwise turning of the Jackbolts with torque, the axial pretensioning force is generated. The bolt being tightened is elongated and by leading in the force into the disc the flange parts are compressed.

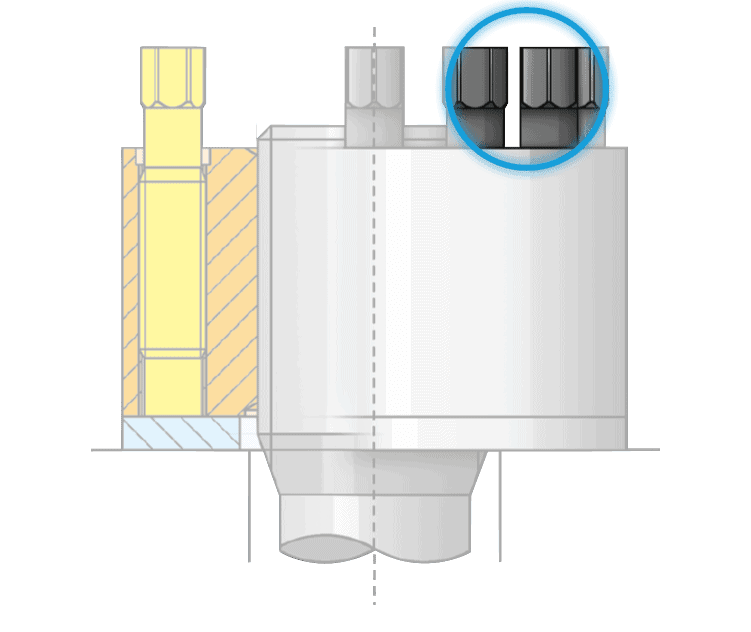

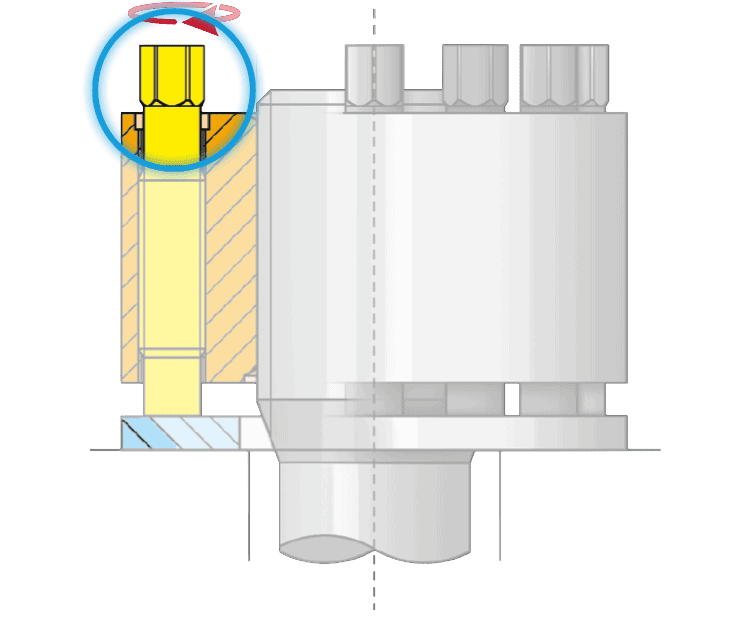

Pretensioning generation

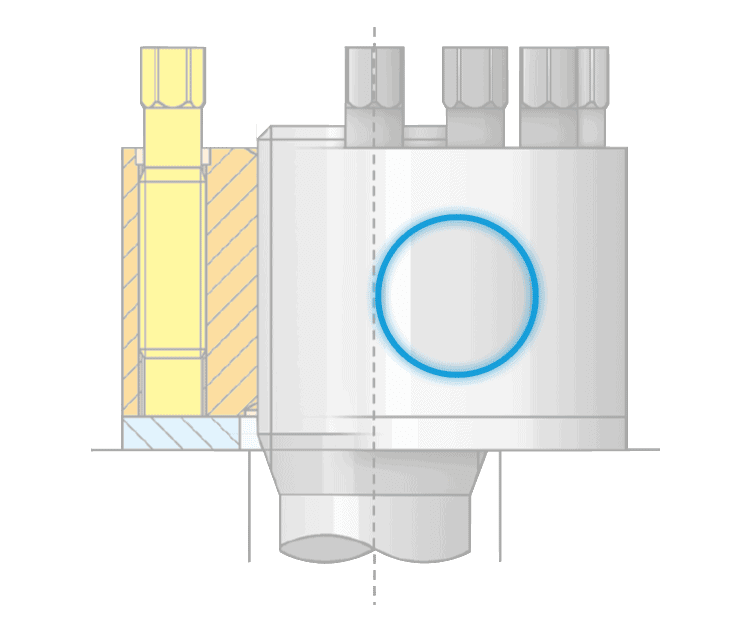

Pretensioning

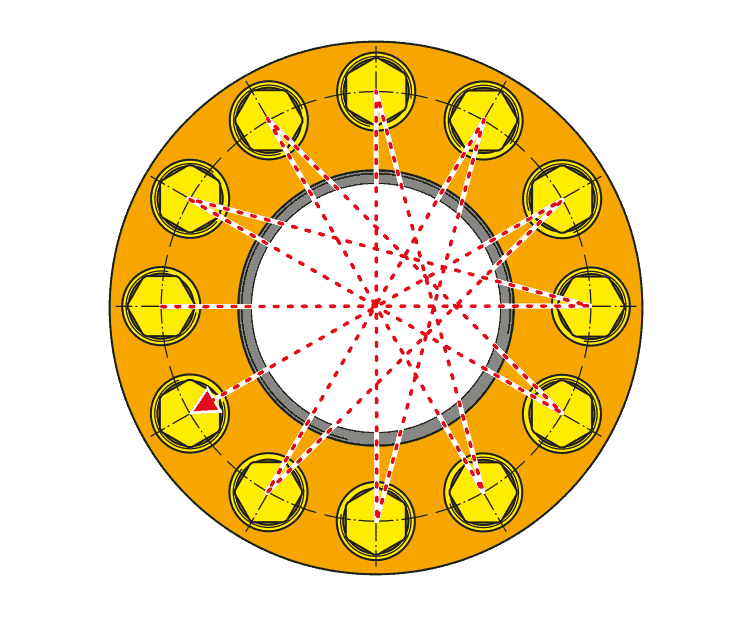

After reaching the required torque, the pretensioning force of the bolt is achieved. The sum of the axial pressure forces of the Jackbolts is in accordance with the overall bolt pretensioning force (axial traction). The main bolt is pretensioned absolutely torsion-free. The Multiple Stud Nut automatically is protected against loosening.

The tightening occurs with stepwise tensioning of the jackbolts.

Advantages

The SCHAAF MSN – Multiple Stud Nuts offer you many advantages compared to conventional fixing devices and methods of mounting:

- Main bolt is pretightened 100 % torsion-free

- No torsion under load (no thread wear)

- Robust, durable and lightweight mode of construction

- Simple and easy mounting and dismantling

- Permanent maintenance-free connection

- Wide choice of sizes and designs

- Anytime quickest control possibility of the pretensioning force

- Mounting with many individuals possible

- Easy pretensioning control

- Tensioning locking at static, alternating and impact loads

- Improves the bolt lifetime because of gentle pretensioning force generation and pure axial load

Versions

The SCHAAF MSN – Multiple Stud Nuts can be manufactured/supplied as follows:

- Compact design

- Standard design

- High-tensile design

- Customer specific solutions up to Ø 1800 mm

- All sorts of threads, standards and others Power transmission elements as e. g. bayonet

- High-tensile steel

- Rust and acid-resistant steels

- Heat-resisting materials

- High-strength aluminium alloys

- Different material combinations

- Burnished, lacquered or chemically nickel-plated

- Requested by the customer

User-defined special designs possible.

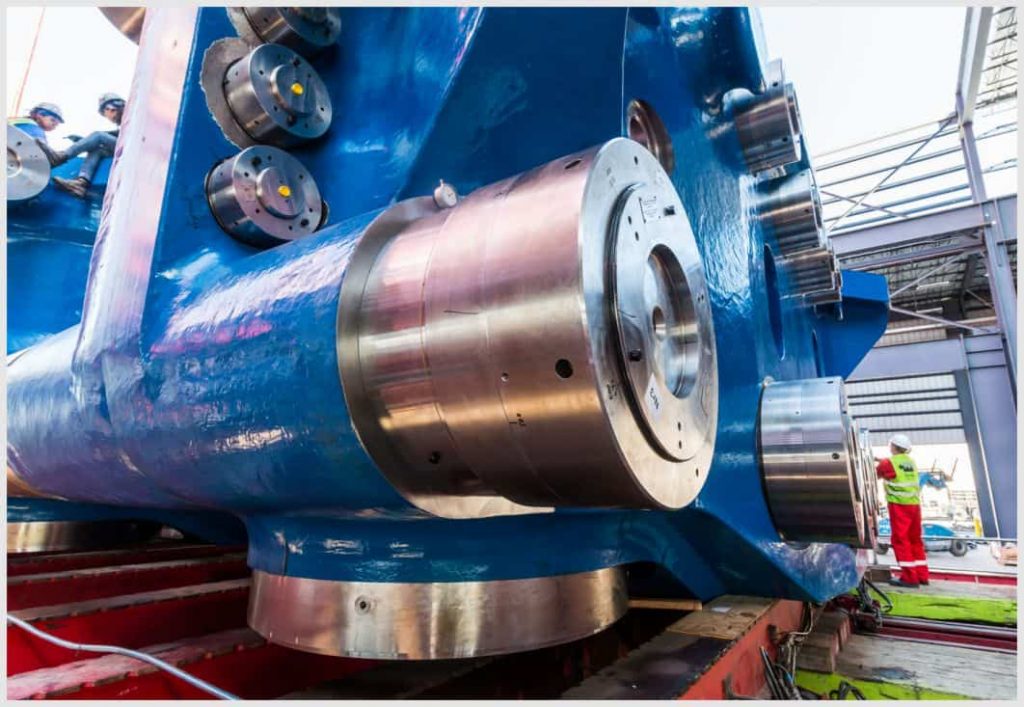

Fields of Application

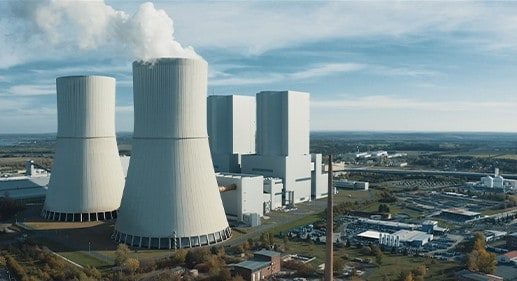

The MSN proves its worth wherever a secure and maintenance-free

connection must be guaranteed.

Examples: General mechanical engineering, Powerplant technology und Engines and gearboxes.

Quality Assurance

All MSN – Multiple Stud Nuts are checked for material quality, dimensional accuracy, proper operation and reliability. They are subject to quality assurance measures during order execution and delivered with detailed documentation.

Services

MSN are, of course, delivered packaged ready for installation and operation.

SCHAAF MSN are user-friendly, reliable and are manufactured in accordance with the highest level of technical know-how. Our highly-motivated staff will be pleased to train your personnel, in situ or at our works, in the general handling of MSN.

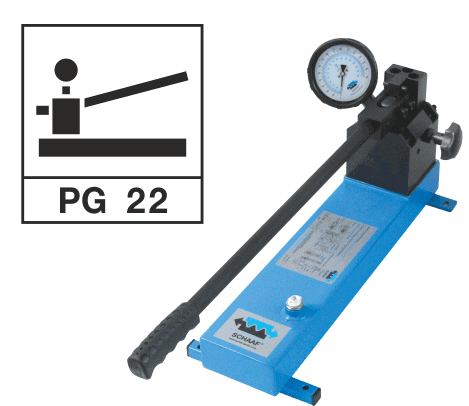

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.