Bolt Tensioners (SSV)

Bolt Tensioners (SSV)

Torsion-free generation of tension force – Economical use of bolt material capacity

A bolt is designed to hold two or more components together. Axial bolt elongation is the only force at work here. Torsion, which is generated, due to friction in the threads and in the support surface, by using torque wrenching methods, means only unnecessary weaking of the components. This requires stronger bolt connections. This disadvantage is no longer existing when using SCHAAF SSV and HM to generate the axial pre-tension. This increases the economic utilisation factor. Axial tension force has been attained by using SCHAAF SSV and HM for bolts with a thread diameter from 8 mm to over 800 mm.

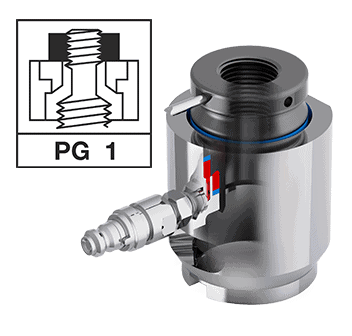

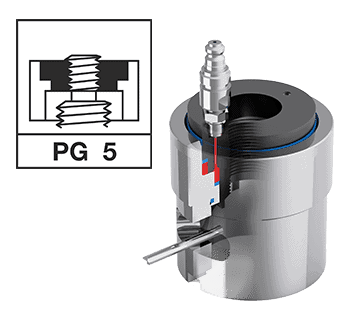

Basic position

Place the SSV onto the bolt to be tensioned and screw the Thread Sleeve down to the Piston surface. A hydraulic high-pressure pump, through a flexible hose, feeds oil into the space between Cylinder and Piston. The hydraulic pressure increases.

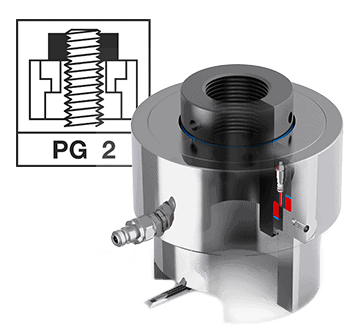

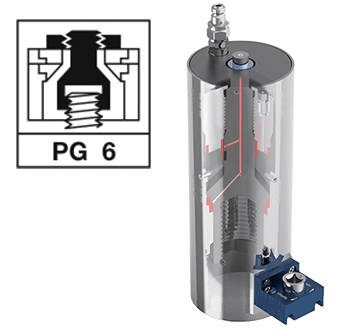

Elongation and compression

As the hydraulic pressure increases, the resulting axial force elongates the Bolt and compresses the flanges. Thus, the Main nut lifts from the flange. On reaching the desired tension, pressurizing is stopped.

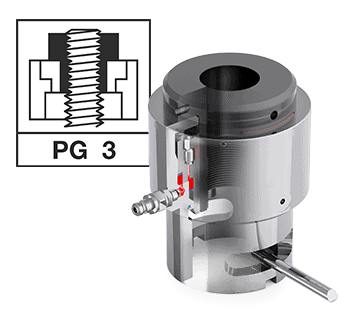

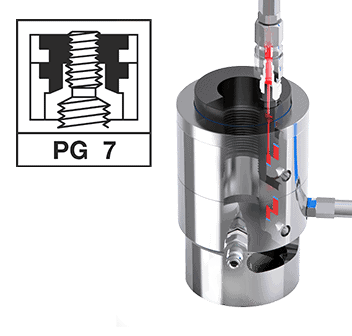

Positioning of the Main nut

The tensioning force is achieved and the Main nut can be turned down to contact the flange. When releasing the oil pressure, the desired tensioning force remains in the bolt connection. After removing the SSV, you may use the equipment for tensioning other bolts.

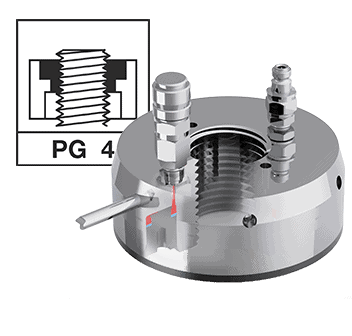

Overview Bolt Tensioners (SSV)

Overview Bolt Tensioners (SSV)

Comparison between:

SSV und HM

- Bolt Tensioners can be removed from the screw joint after achieving the desired pretensioning force. Hydraulic Nuts remain on the screw joint or assembly.

- The pretensioning force, obtained in the screw joint by a Bolt Tensioner, is maintained by a mechanical element which is a nut in most cases. With a Hydraulic Nut (HM), however, the axial pretensioning force is maintained by the residual pressure in the hydraulic chamber or pressureless if the HM is equipped with a lock nut.

- The Bolt Tensioner is removable and can pretension several screw joints one after the other, in contrary to the Hydraulic Nut remaining in place.

- Since the Hydraulic Nuts remain in situ, compared with Bolt Tensioners they allow quicker change-over times at clamping / releasing and shorter finding of residual pretensioning force.