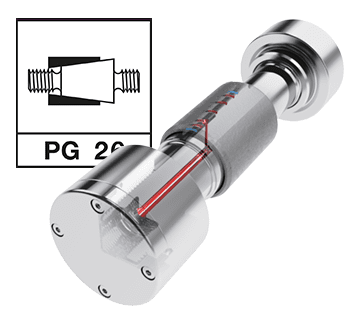

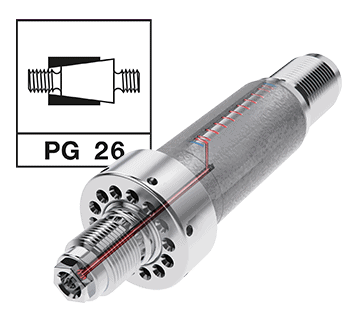

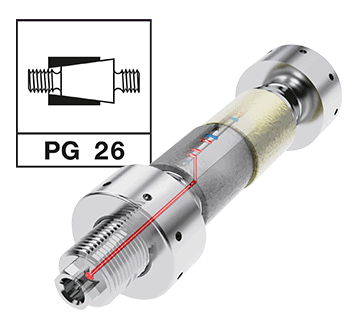

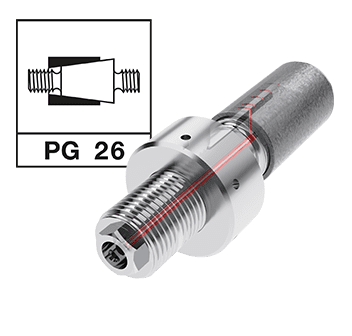

ExpaBolt

Fast positive and non-positive connections for blind holes

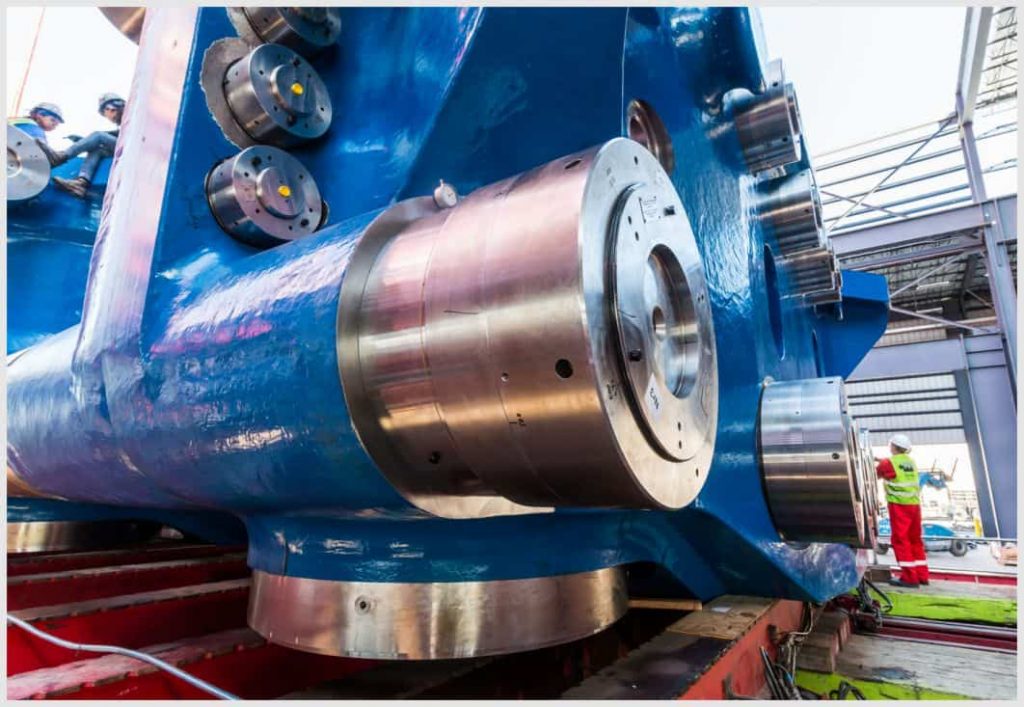

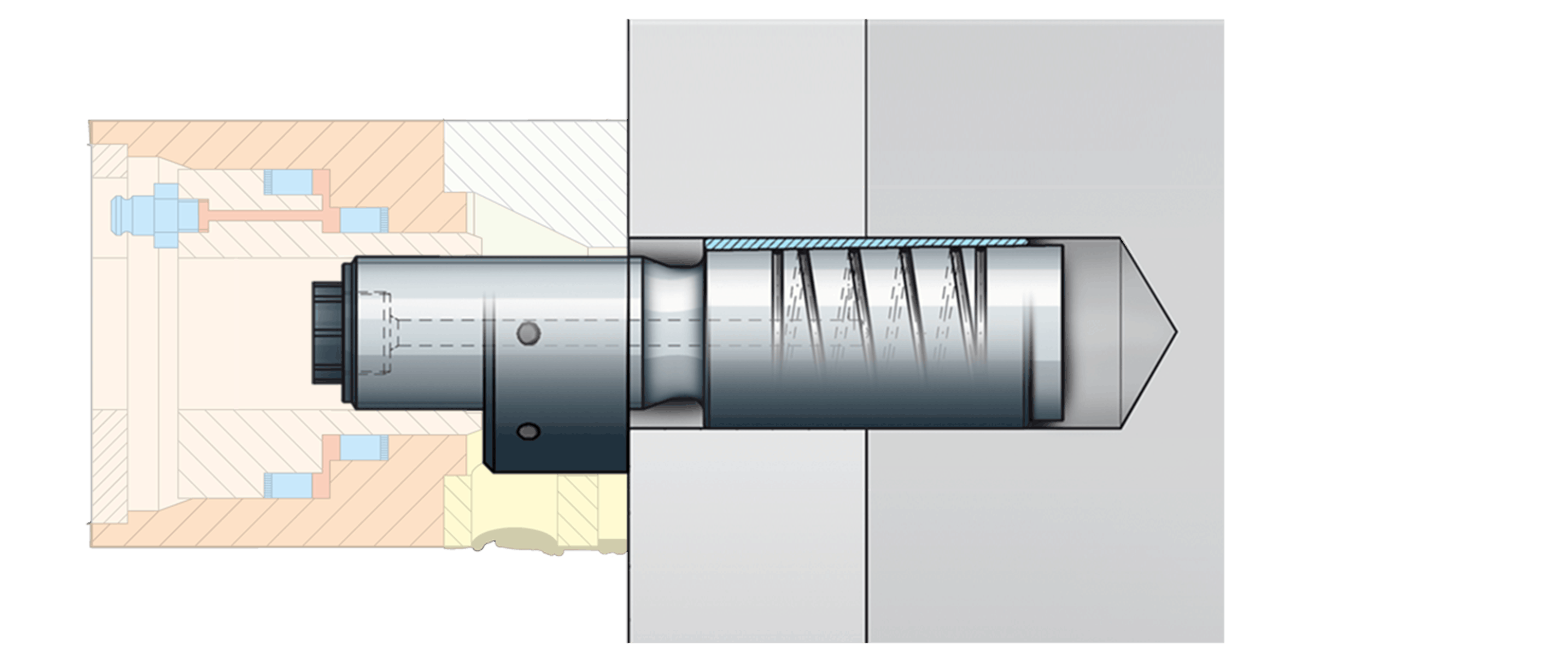

With SCHAAF ExpaBolt, form-fit connections of flange joints with blind bores are realised. Due to the positive locking, high torques or shear forces can be transmitted. Due to the axial clamping force additional axial loads can be transmitted by friction.

Expa = Expansion = 100% positive locking in the flange bore Ten = Tension = frictional connection for the joint

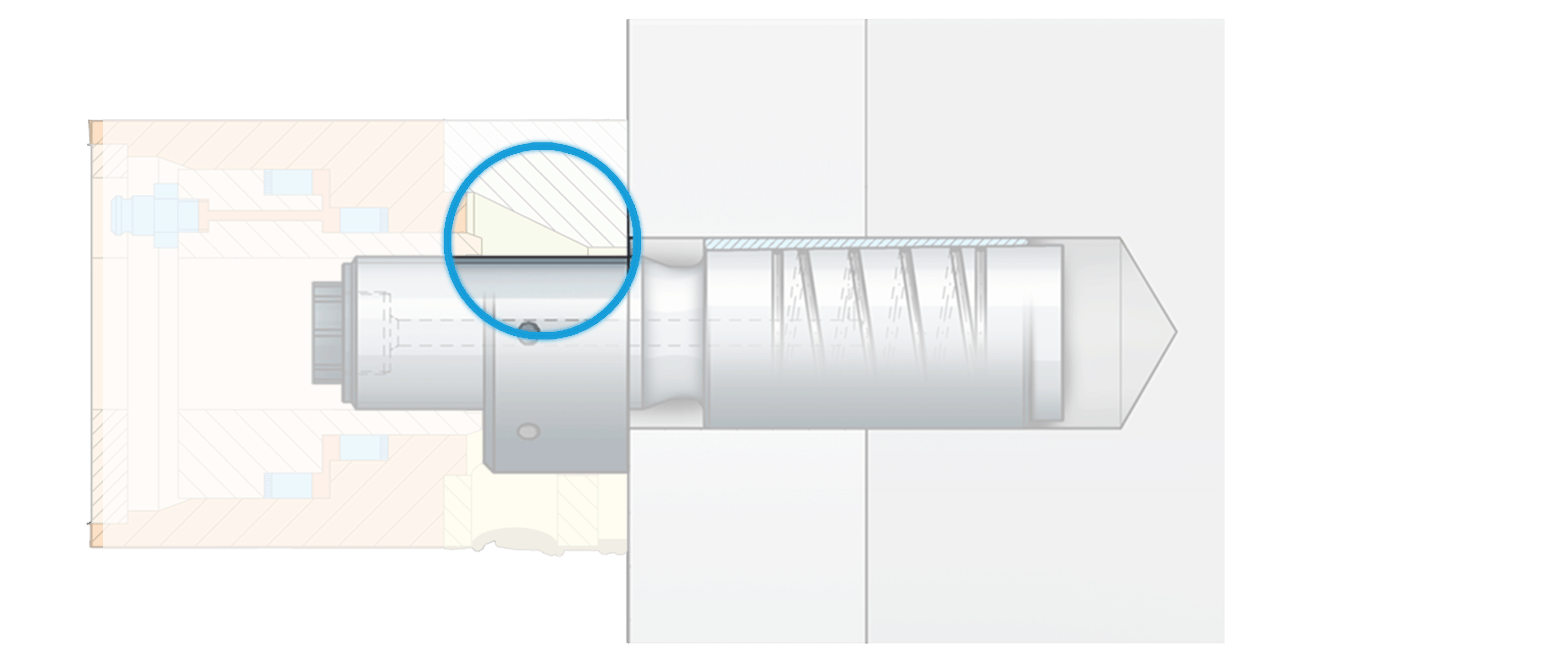

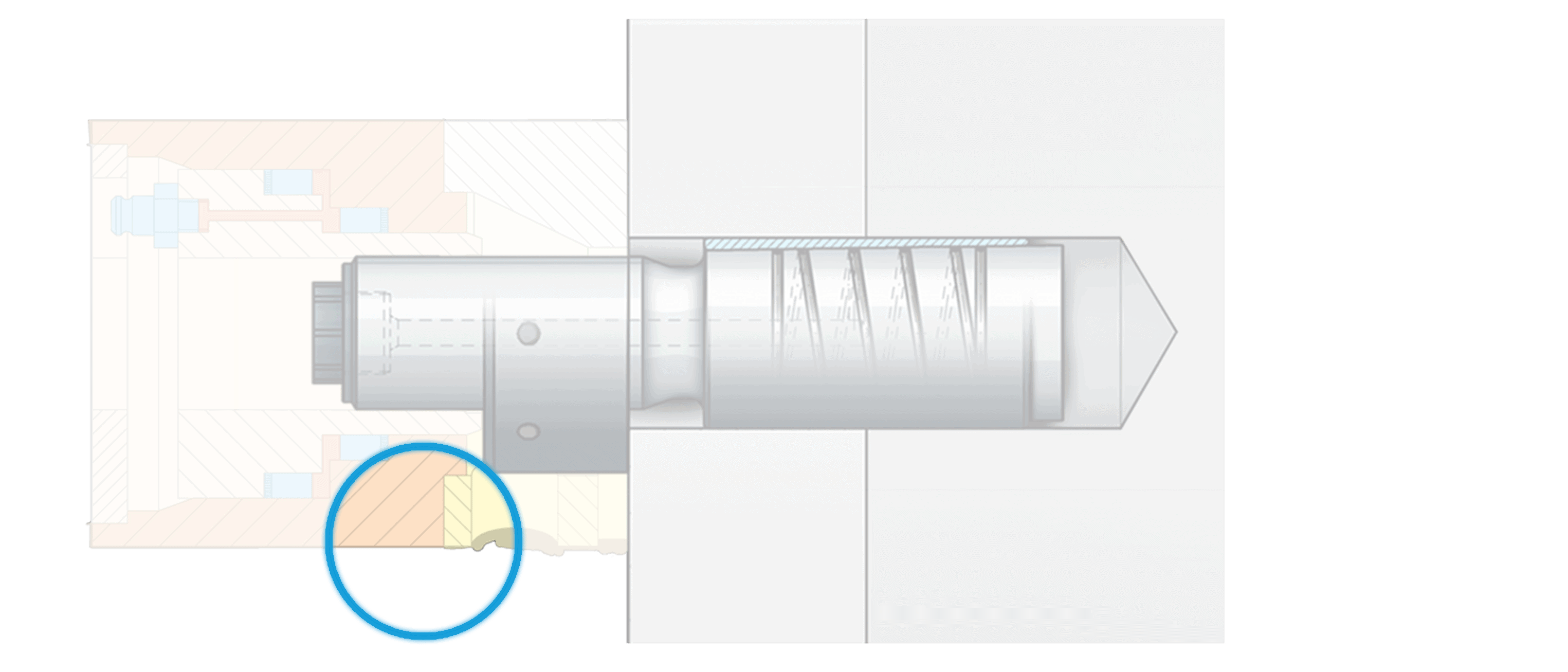

Pressure connection bore

e to press out the Tapered Bolt.

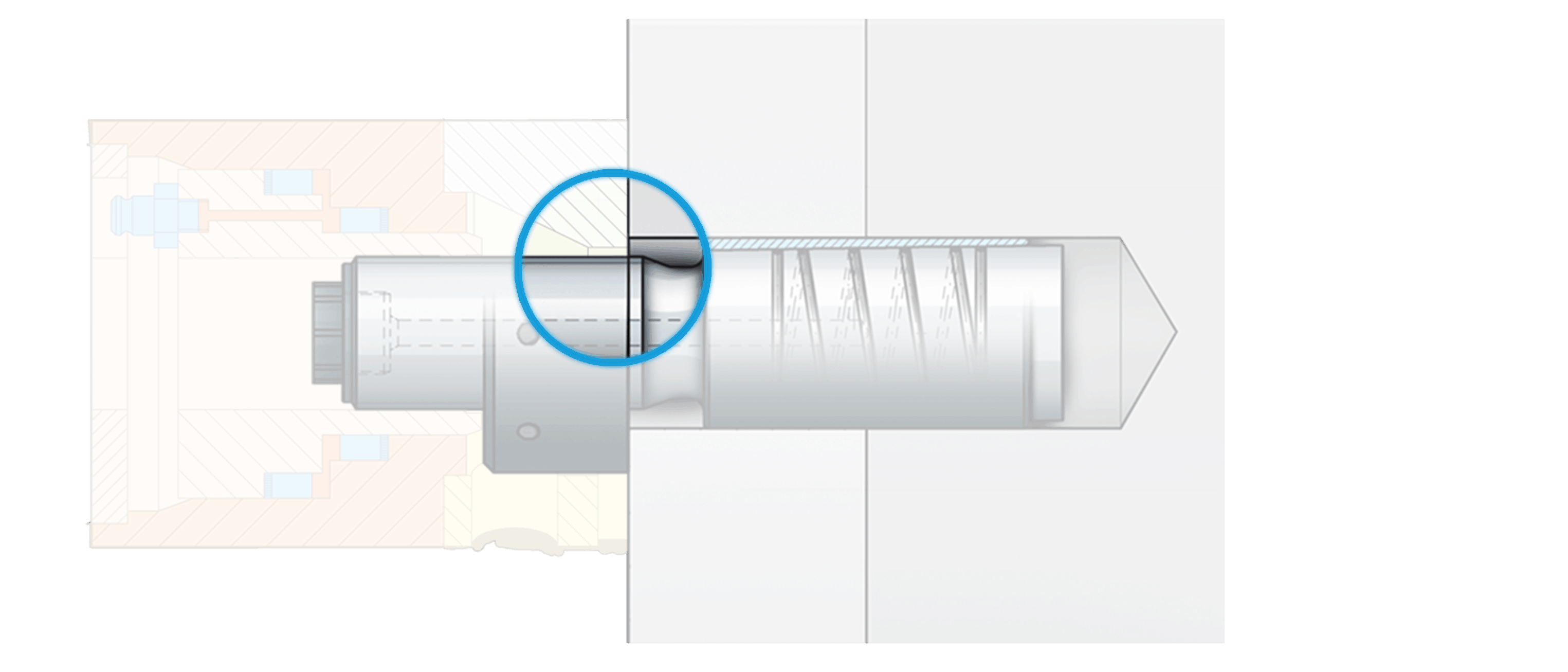

Tapered Bolt made of high-strength quenched and tempered steel

l to absorb radial shear forces and a high axial pre-tensioning force.

SCHAAF Bolt Tensioner (SSV)

up to 4000 bar hydraulic pressure.

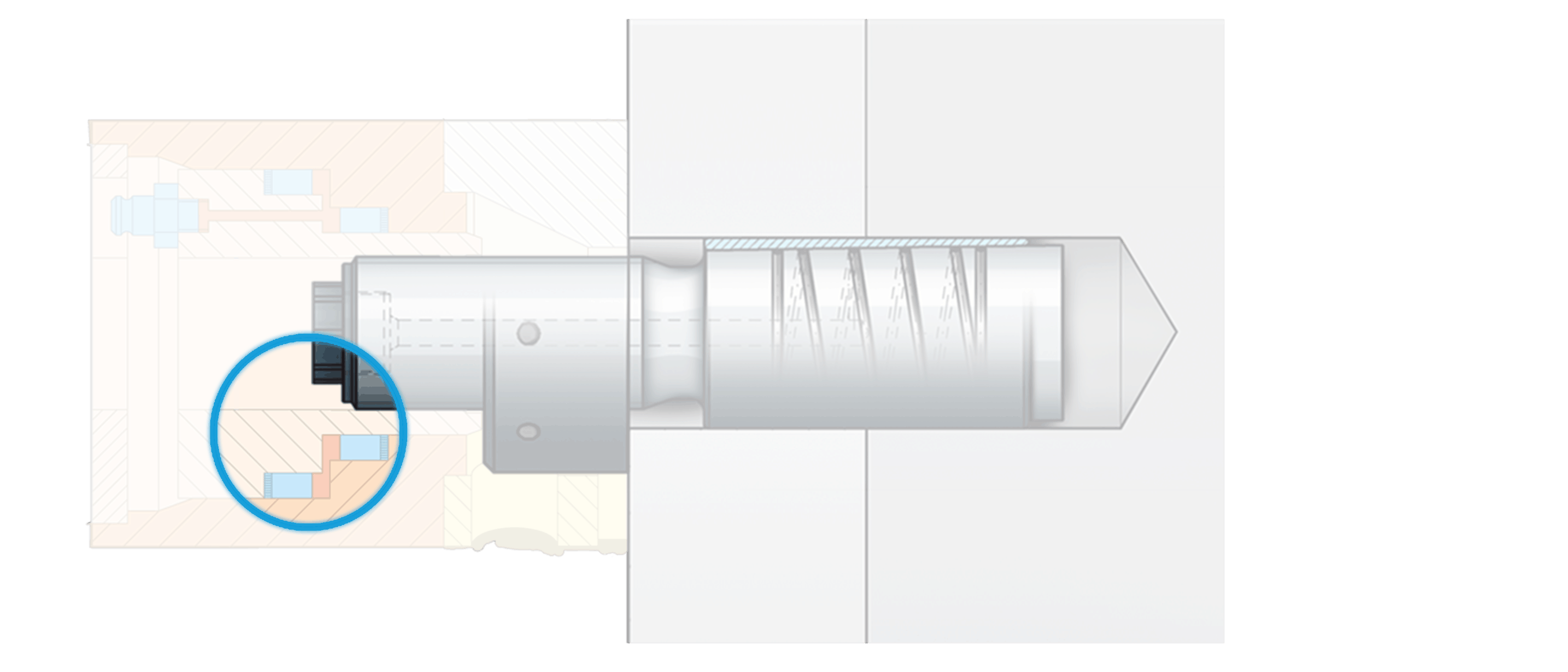

Positioning ring

g to hold the Conical Sleeve in position while the Tapered Bolt is being pulled into the Conical Sleeve. This results in expansion (Expa) of the sleeve and produces a press fit in the bore.

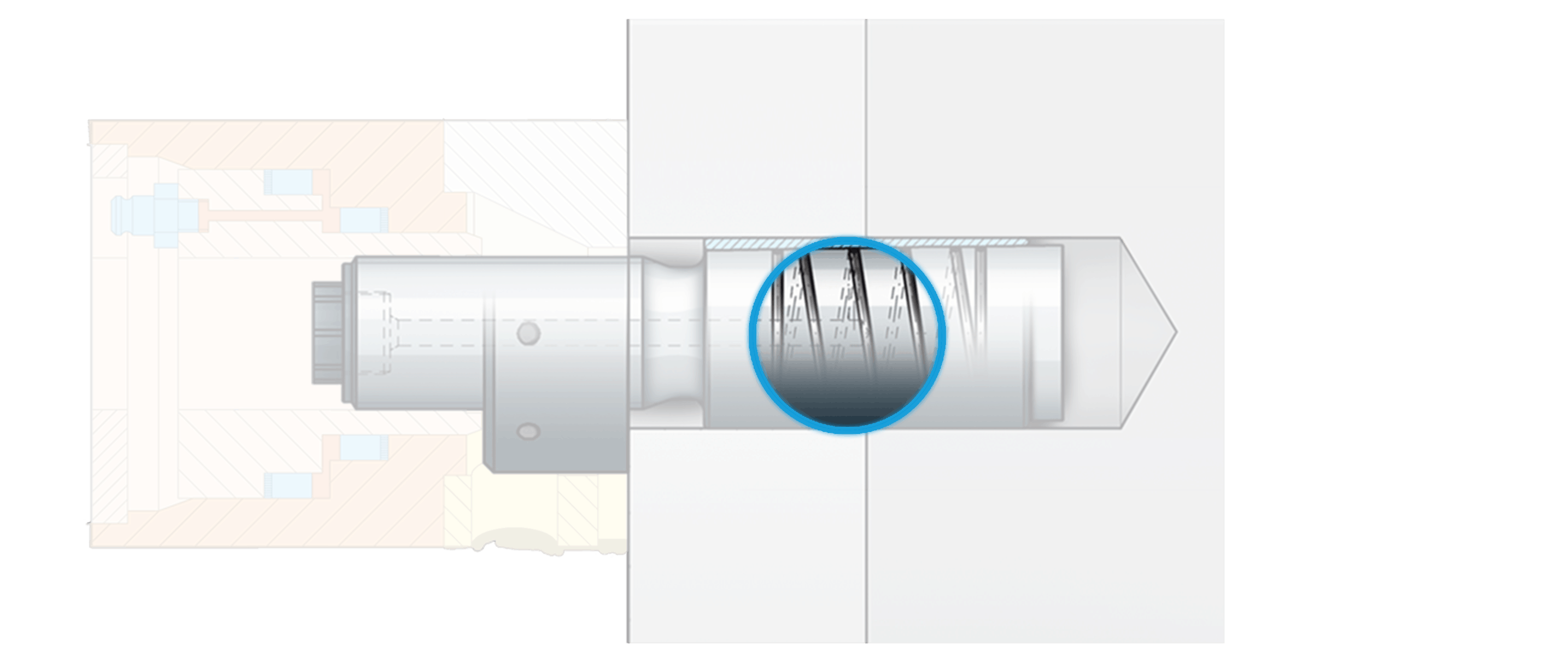

Guaranteed reusability

even after years of use. Again and again.

Pressure distribution grooves on the taper

to allow easy removal even after years of use.

Advantages

ExpaBolt offers the following advantages over normal connections:

- Fast radial and axial bracing for components that have to absorb torques / shear force and / or bending moments

- 100% positive locking

- Simple and quick installation and removal of ExpaBolt even after years of use – nearly unlimited times

- Reusable after removal, again and again – no sparebolts required

- Torsionally and flexurally rigid connection even with sudden changes in the rotational speed, the torque, direction of rotation or direction of load

- No jammed or oversized bolts any longer

- High torque transmission, completely free from backlash

Overview ExpaTen

Quick form and force fit connections with detachable axial tensioning system (Quick Locking).

Versions

The standard version of the SCHAAF ExpaBolt comprises the following

components:

- Tapered Bolt and Conical Sleeve of high-strength quenched and tempered steel for maximum shear strength and axial load capacity

- Round Nut

- Two ultra-high-strength Round Nuts

- Fine thread for maximum fatigue strength

- Pressure connection bore and pressure distribution grooves on the taper for easy removal of the Tapered Bolt

- Protective caps in various designs and materials

Areas of Application

SCHAAF ExpaBolt is the optimum solution wherever high forces (torques) must be transmitted and, at the same time, easy removal must be ensured.

For example ship drive shafts, powerplants, crushers, steel and non steel mills and windturbines.

Quality Assurance

All ExpaBolt Bolts are checked for material quality, dimensional

accuracy, correct functioning and load-resistance. During order

execution, they are subject to continuous quality assurance measures

and are supplied together with detailed technical documentation.

Services

ExpaBolt are, of course, supplied packaged, ready for installation and use.

SCHAAF ExpaBolt are user-friendly, reliable, and manufactured in accordance with the highest level of technical know-how. Our highly-motivated staff would be pleased to train your personnel, in situ or at our works, in mounting and dismantling the bolts.

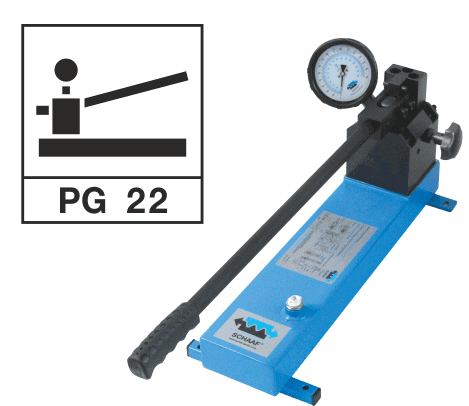

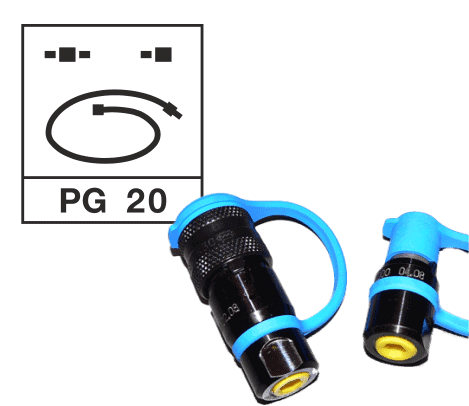

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.