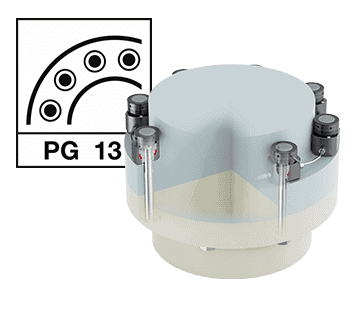

Hydraulic Nut PG13

Axial Bolt Tensioning using High-Pressure Hydraulic

Cost-reducing - Powerful - Reusable

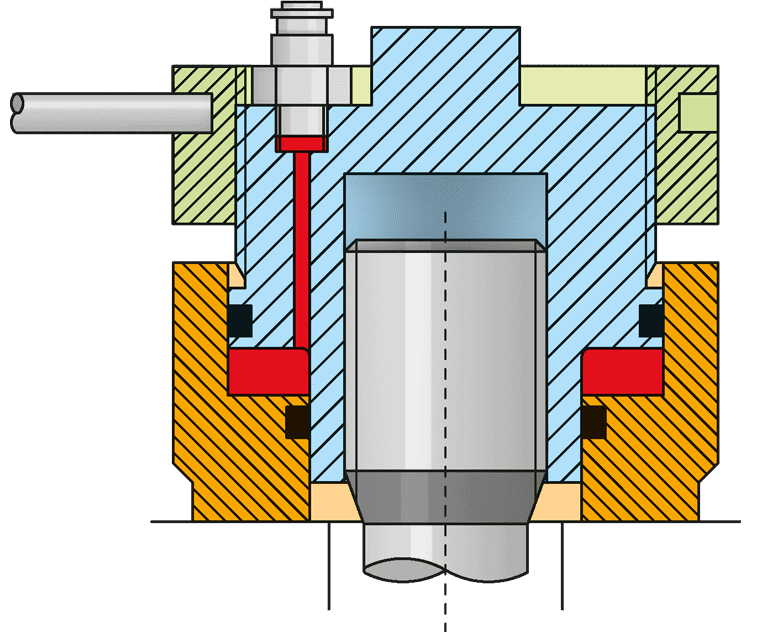

The distinguishing feature of the Hydraulic Nuts of product group 13 is that several Hydraulic Nuts are arranged within or on a ring structure or alike and that, thus, several bolts can be tensioned at the same time.

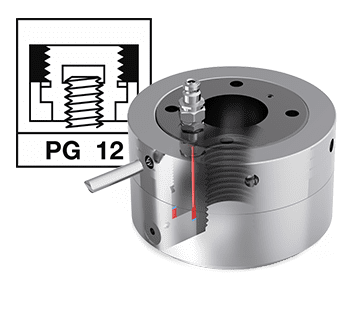

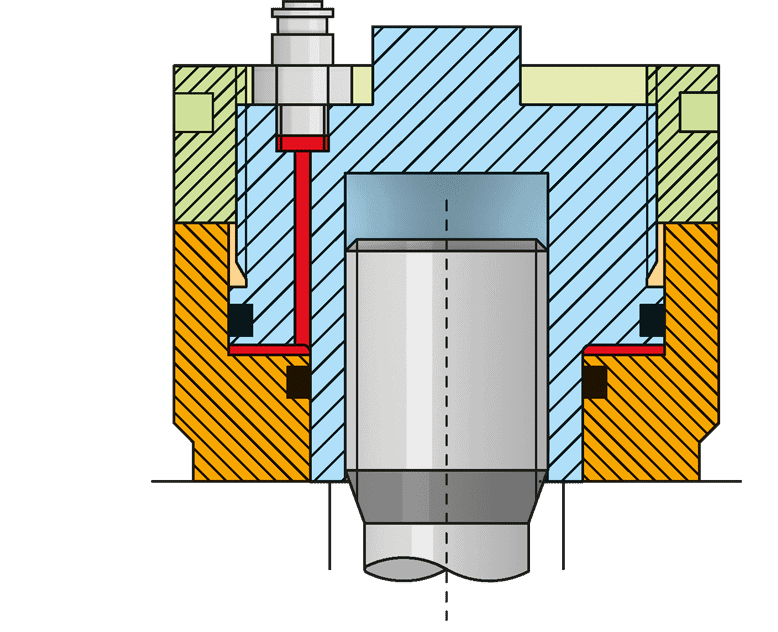

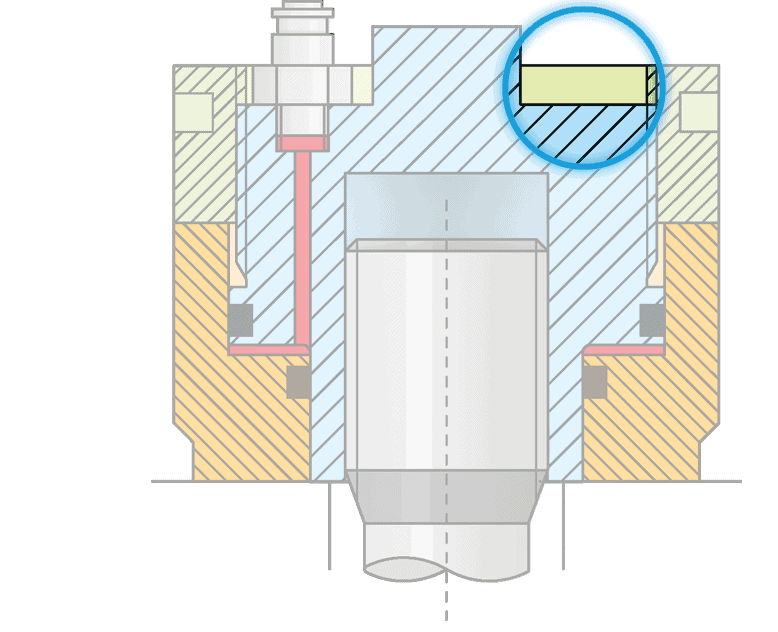

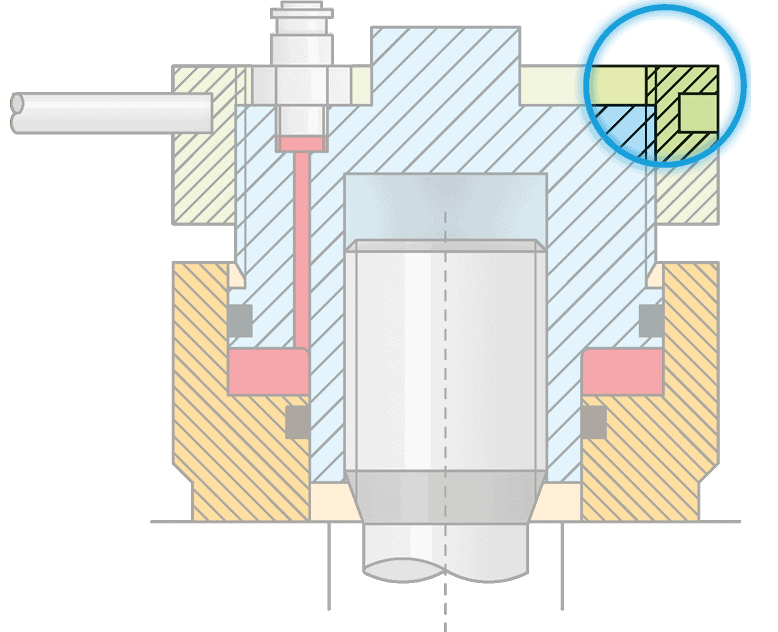

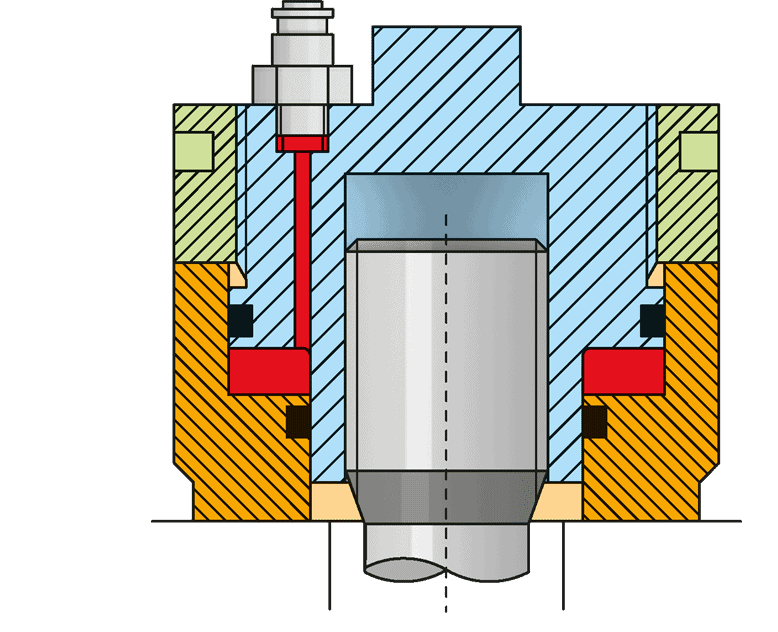

Basic setup

Screw the Hydraulic Nut (HM) on the bolt to be pretensioned, and down to the flanges' surface. A hydraulic high-pressure generator pumps the oil through a high-pressure hose into the space between cylinder and piston. The hydraulic pressure rises.

Piston

Bolt to tension

Cylinder

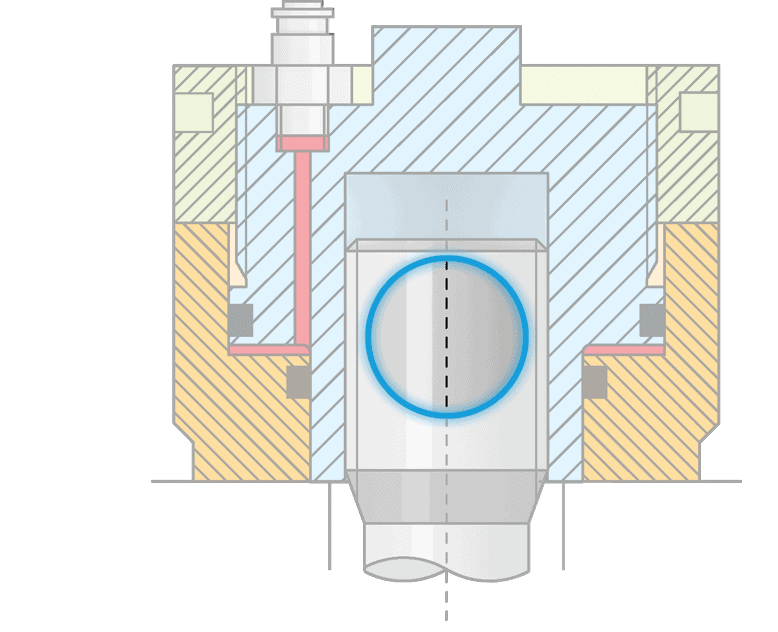

Bolt elongation

Through the rising pressure and the resulting axial force, the bolt is elongated and the flange parts are compressed. The lock nut is lifted off the cylinder. When the preset pre-tensioning force is achieved, the pressure supply is stopped.

Locking Nut

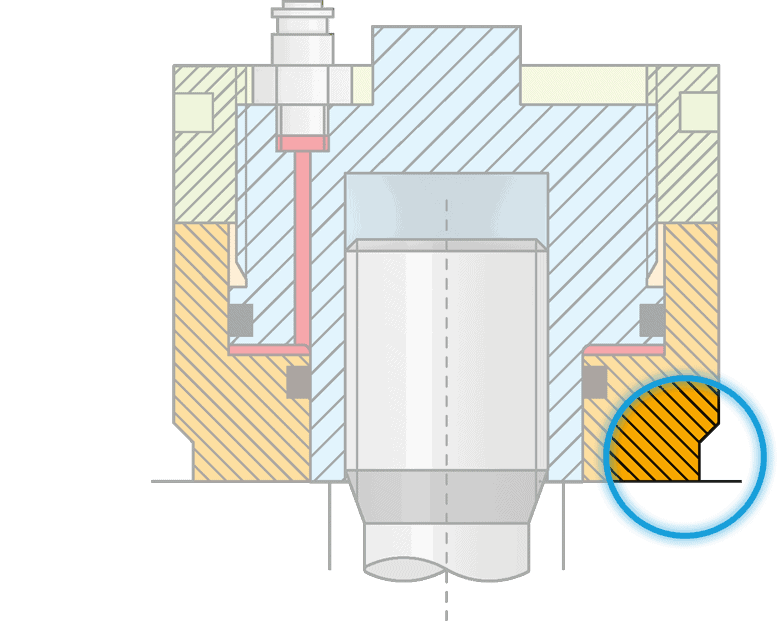

Screwing the lock nut

The pre-tensioning force has been achieved and the lock nut is turned by hand down to the stop face of the cylinder. Thus, the pre-tensioning force is maintained within the screw joint and the hydraulic may be released. The Hydraulic Nut remains on the bolt connection.

Advantages

„Crossover-tightening“ of several bolts at several points is no longer necessary, since SCHAAF SSV and HM offer the possibility of tightening all the bolt connections simultaneously with exactly the same tensioning force. This also applies when increasing the tensioning force.

As opposed to thermal screw starting procedures, SCHAAF SSV and HM make it possible to eliminate different gaps between individual components. Each bolt can be tensioned with exactly the same force and not over the same distance!

SCHAAF SSV and HM make it possible to apply a residual tensioning force by means of test force stress application in order to determine if any settling of the screw may occur, and if so, to eliminate it.

With a compact unit and the ability to interchange the component parts relating to the size of the bolt, SCHAAF SSV can also be used for other thread sizes.

SSV and HM will dramatically save time required for tensioning applications. This effect increases for higher tensioning

forces, larger bolt thread diameters and also the installation of several SCHAAF SSV or HM. Time savings up to 99% are

possible! It is no longer necessary to apply large torque by hand. There is a number of handling features available, designed to make work easier with SCHAAF Bolt Tensioners and Hydraulic Nuts, especially when it comes to large dimensions.

Features HM PG13

- optimum way of generating the same pre-tensioning force in all screws simultaneously

- shortest set-up times

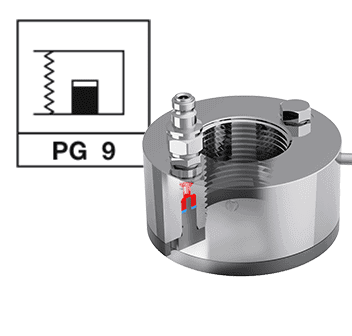

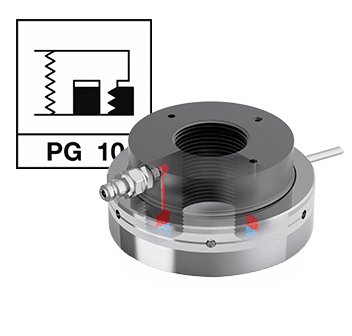

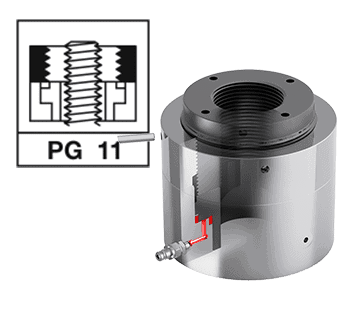

More Hydraulic Nuts

Versions

In addition to a number of standardized Bolt Tensioners and Hydraulic Nuts, SCHAAF has already delivered thousands of customized axial Bolt Tensioners. The Design on Demand CAD system allows to realize customer solutions very quickly. Based on axial pre-tensioning technics, a number of patented, specialized solutions have been developed during the last years. Bolt Tensioners, Hydraulic Nuts and ExpaTen, as well as the A-Loc and EcoRolls, both developed especially for rolling mills, all represent a 100% system solution with SCHAAF’s accessories such as high-pressure hoses and high-pressure generators.

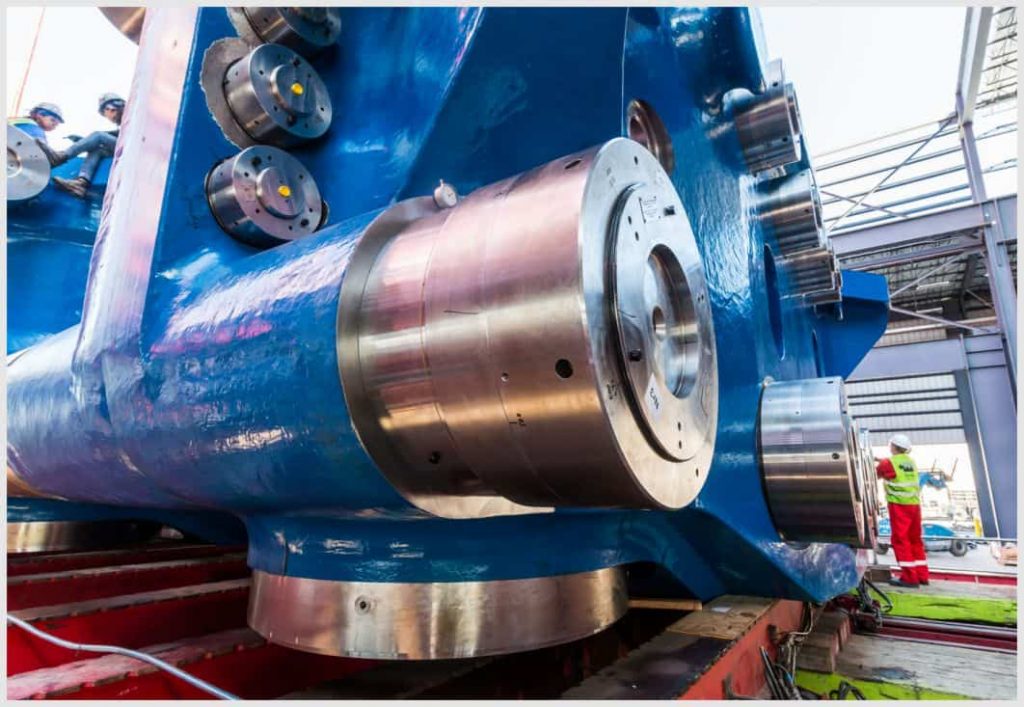

Areas of Application

The application areas for Bolt Tensioners and Hydraulic Nuts are unlimited. The great amount of user solutions have resulted in a great number of various designs. For this reason it is not always possible to classify all Bolt Tensioners and Hydraulic Nuts into a specific product group. For example, the tensioning force can be transmitted by a thread or a bayonet. Please contact us for your special application.

Quality Assurance

All Bolt Tensioning Tools and Hydraulic Nuts are checked for material quality, dimensional accuracy, proper operation, and pressure resistance.

They are subject to quality assurance measures during order execution and delivered with detailed documentation.

Services

SSV and HM are, of course, delivered packaged, ready for installation and operation.

SCHAAF SSV and HM are user-friendly, reliable and are manufactured in accordance with the highest level of technical know-how. Our highly-motivated

staff will be pleased to train your personnel, in situ or at our works, in the general handling of high-pressure equipment.

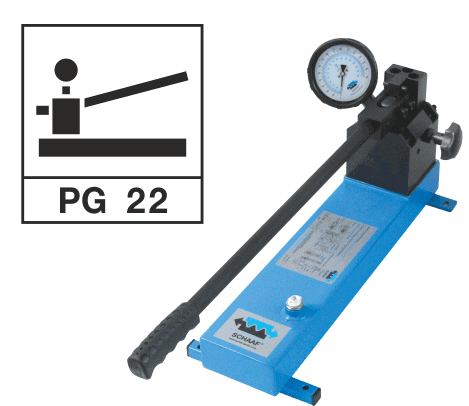

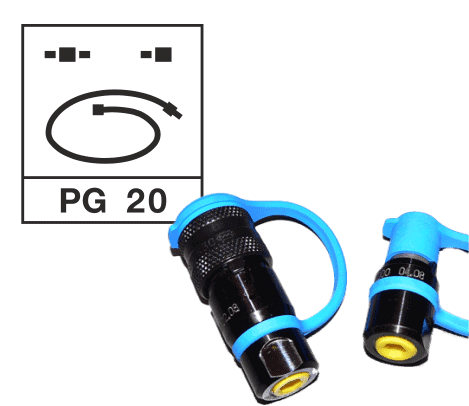

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.