FSE

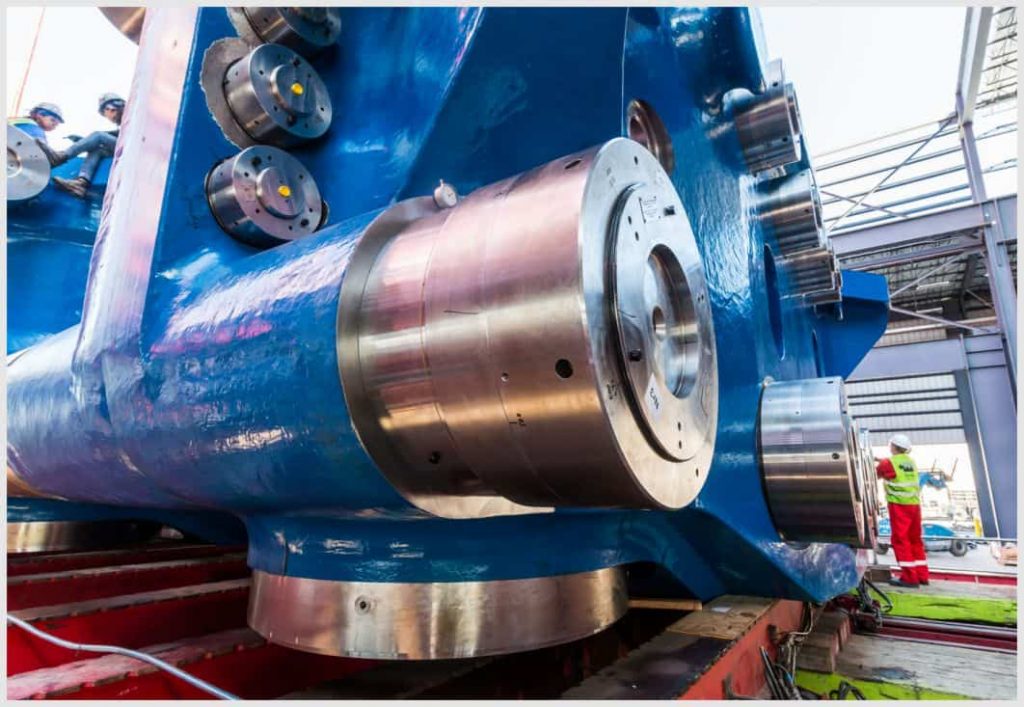

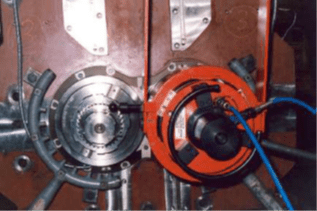

System for a non-positive connection between shaft and roller ring.

Mounting / Dismounting

To mount or remove the rolling ring, the control unit is connected to the device and the corresponding program is started. The process is processed fully automatically. After the end of the program, an acoustic and/or visual feedback is given to the operator.

Advantages

- Robust, compact, maintenance-friendly and durable design

- Special steel mills designed for industrial use

- Powerful hydraulic unit with an output of 3kW and a flow rate of 2.4l/min at 700bar

- 2 hydraulic circuits, each with 1 pressure gauge Ø160mm or optional digital displays for readability from a distance of up to 25m

- 2 pre-configured programs, selectable using a selector switch

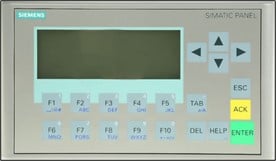

- All program parameters can be adjusted with the built-in HMI

- Password-protected parameter input

- Optional, acoustic signal when the working pressure is reached

- Optional radio remote control with emergency stop for maximum flexibility

- Tool tray made of oil-resistant rubber covering

- Various connection voltages possible

All high-pressure units

Mounting Documentation System for controlling and monitoring the axial hydraulic tightening process of bolts.

Electro-hydraulic two-circuit high-pressure automatic control system for fully automatic pressing of hubs onto shafts and separating

Ready-to-use air-hydraulic pump up to 2,500 and 4,000 bar hydraulic pressure

Versions

- TD 200 mit S7-200 CPU

- KP300 mit S7-1200 CPU

Areas of Application

Quality Assurance

All FSE are checked for 100 % process security. During order handling, they are accompanied by ongoing quality assurance measures and supplied

with extensive documentation.

Services

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.