FSE

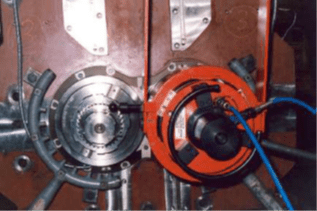

System for a non-positive connection between shaft and roller ring.

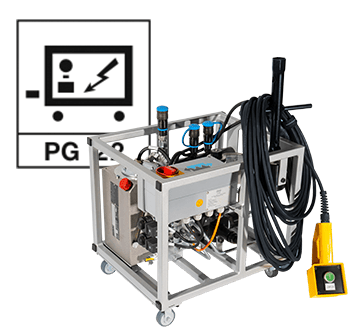

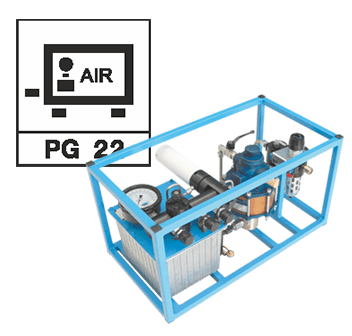

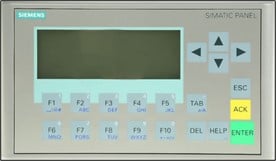

The “FSE” is a “mobile control unit” designed to meet the needs of the steel industry. The system is used to press rolling rings on and off. The high-pressure control unit generates the hydraulic pressure required for the mounting and dismounting process. These processes are monitored by a modern controller; the program sequence as well as all pressure and time values are optimally set at the factory. All important parameters can be adjusted using the built-in manual input device (HMI).

Mounting / Dismounting

To mount or remove the rolling ring, the control unit is connected to the device and the corresponding program is started. The process is processed fully automatically. After the end of the program, an acoustic and/or visual feedback is given to the operator.

Ventajas

- Robust, compact, maintenance-friendly and durable design

- Special steel mills designed for industrial use

- Powerful hydraulic unit with an output of 3kW and a flow rate of 2.4l/min at 700bar

- 2 hydraulic circuits, each with 1 pressure gauge Ø160mm or optional digital displays for readability from a distance of up to 25m

- 2 pre-configured programs, selectable using a selector switch

- All program parameters can be adjusted with the built-in HMI

- Password-protected parameter input

- Optional, acoustic signal when the working pressure is reached

- Optional radio remote control with emergency stop for maximum flexibility

- Tool tray made of oil-resistant rubber covering

- Various connection voltages possible

Todas las unidades generadoras de presión

Bomba de alta presión electro-hidráulica para altas velocidades de flujo y salidas de hasta 4000 bar

Sistema de Montaje de Documentación para el control y supervisión del proceso axial hidráulico de sujeción de pernos.

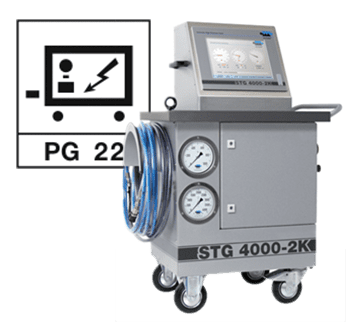

Sistema de regulación y control de alta presión electrohidráulico de dos circuitos para presionar y aflojar de forma totalmente automática los cubos de los ejes

Bomba hidroneumática lista para usar

hasta 2.500 y 4.000 bar de presión hidráulica

Versiones

- TD 200 mit S7-200 CPU

- KP300 mit S7-1200 CPU

Areas de Aplicación

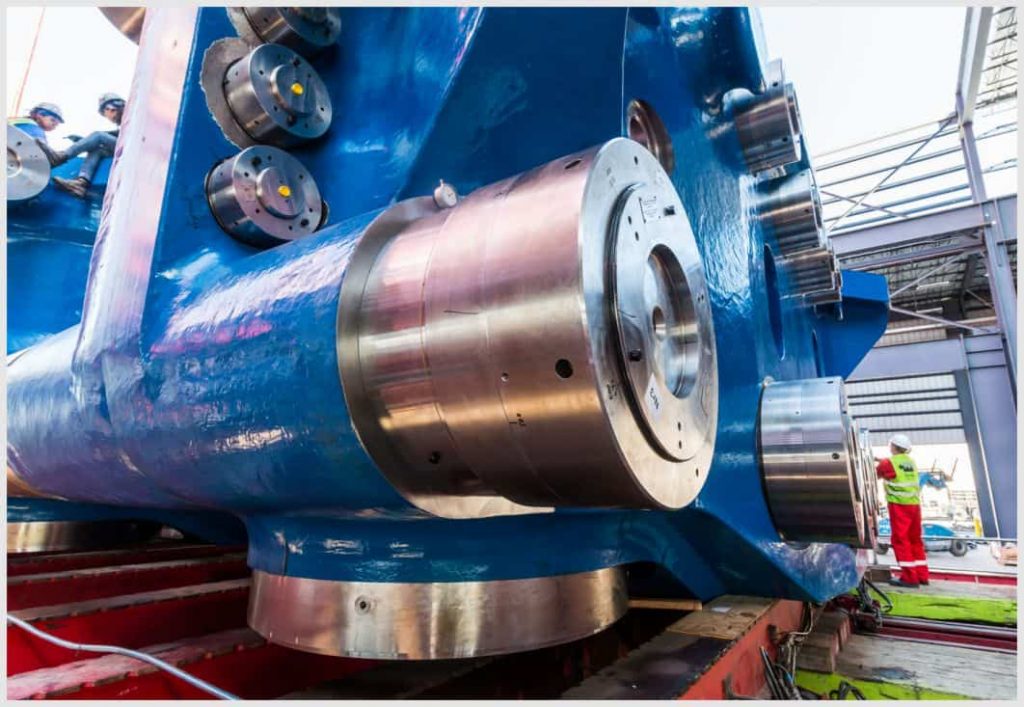

The SCHAAF FSE has proven itself exclusively in steel works, namely in the rolling mill.

There, the hot raw material is pushed through stands with rolling rollers until the desired material thickness is reached. Depending on the type of material required or if the rollers used are too worn, new or different roller rings are required. This is where the FSE is used in combination with the A-LOC tool.

Sello de Calidad

All FSE are checked for 100 % process security. During order handling, they are accompanied by ongoing quality assurance measures and supplied with extensive documentation.

Servicios

SCHAAF FSE are user-friendly, reliable, and manufactured in accordance with the highest level of technical know-how. Our highly-motivated staff would be pleased to train your personnel, in situ or at our works, in the general handling

and operation of the mobile and stationary control unit. In this way, all the process parameters can be entered optimally in order to achieve maximum process monitoring and safety. Of course, the FSE are supplied ready for operation.

Equipo compatible adicional

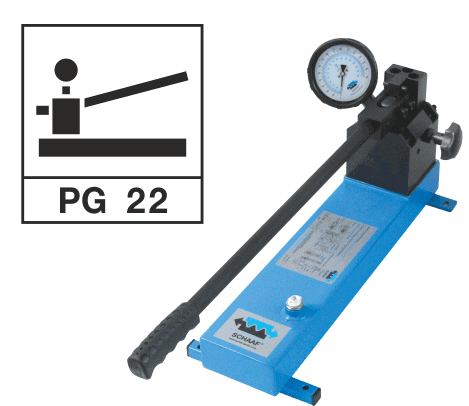

Bomba de palanca manual completamente ensamblada y lista para su uso inmediato para presiones de hasta 4000 bar

Generadores de alta presión perfectamente adaptados para nuestras herramientas de alta presión.

Medios y más

Online Meeting / Webinar

Regístrese para una presentación gratuita en línea sobre este producto.