FSTS

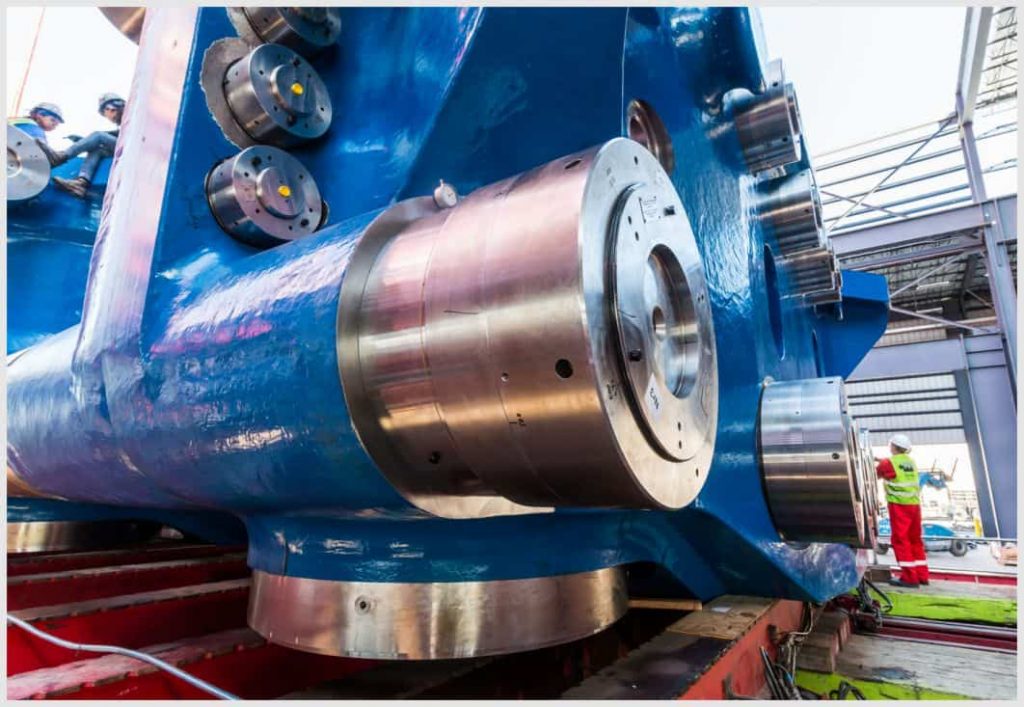

SCHAAF solution for a Tower Flange Stud Tensioning System Documentation – Efficiency – Quality

FSTS

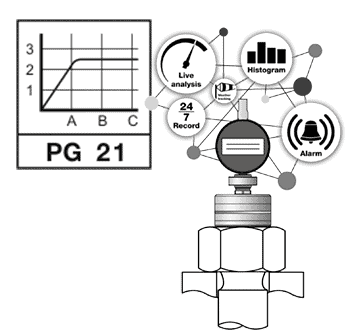

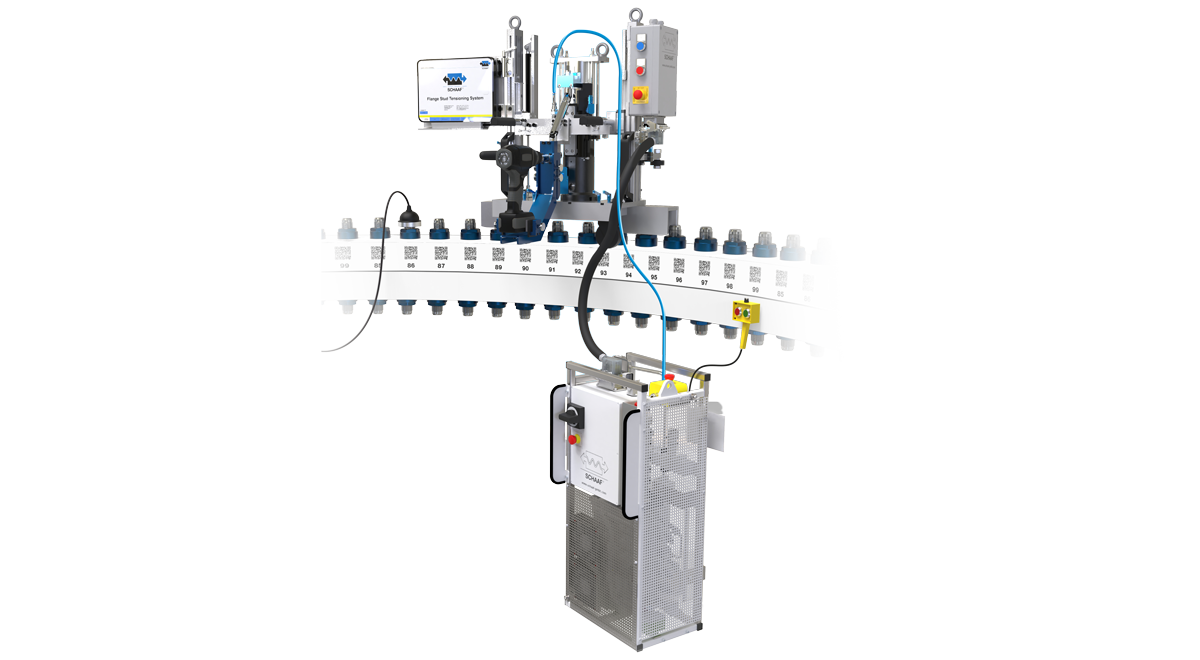

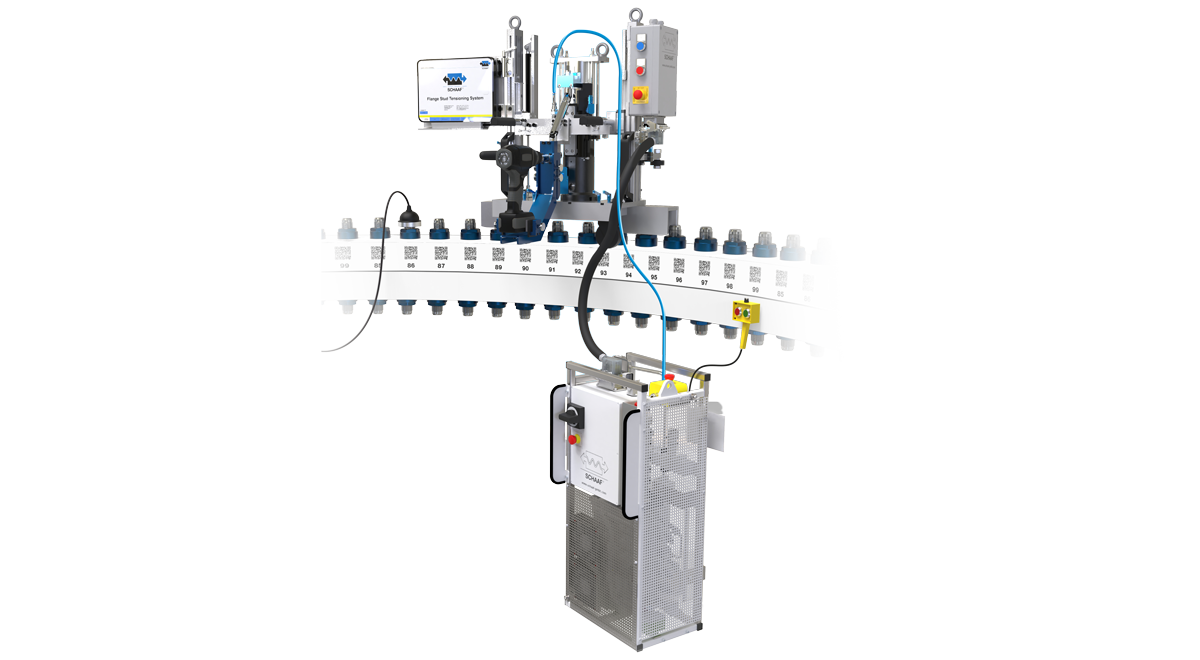

The illustration describes the optimized system for flange stud tensioning tools, including reading input data and output tracking data. Modifications to fulfill other requirements are possible.

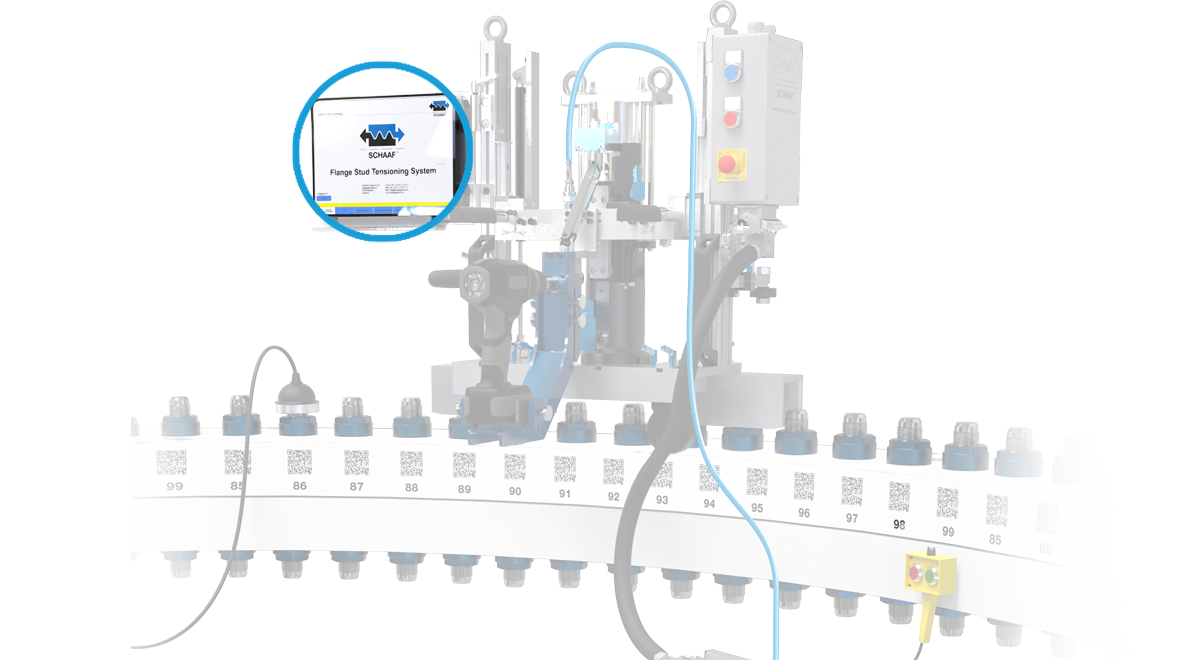

Handheld tablet

includes camera for scanning, WLAN and optional UMTS for Data transfer.

Electrohydraulic pump unit

with up to 3,500 bar pressure. Electric connection for 230V / 400V (3P+N+E), battery or any other.

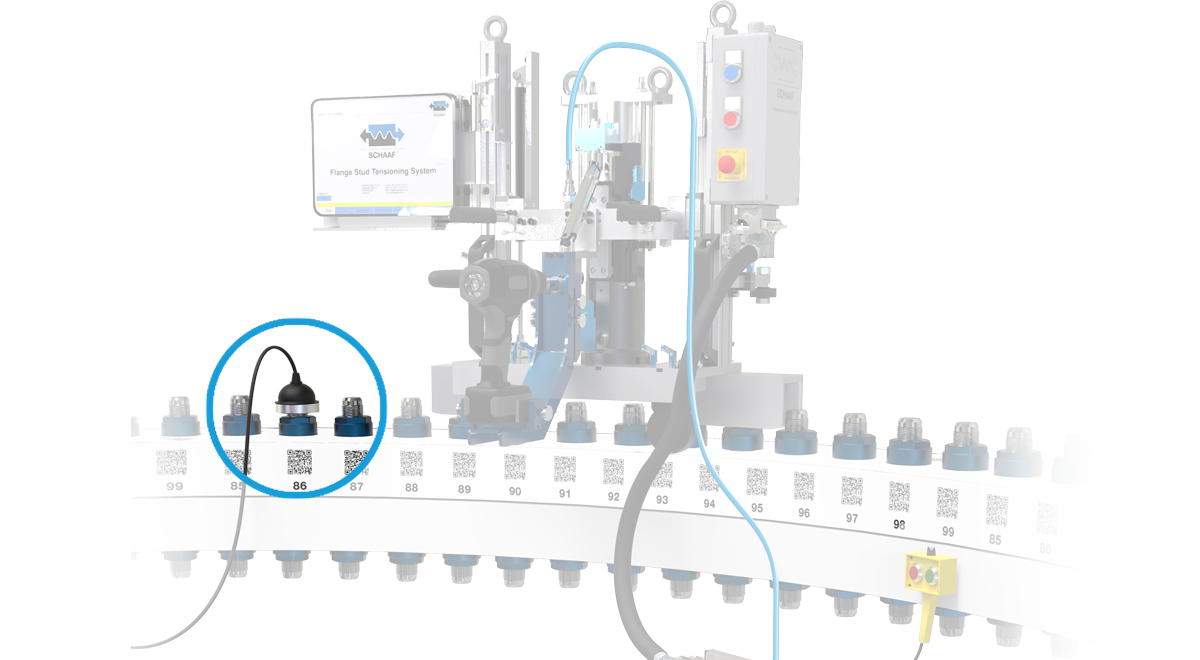

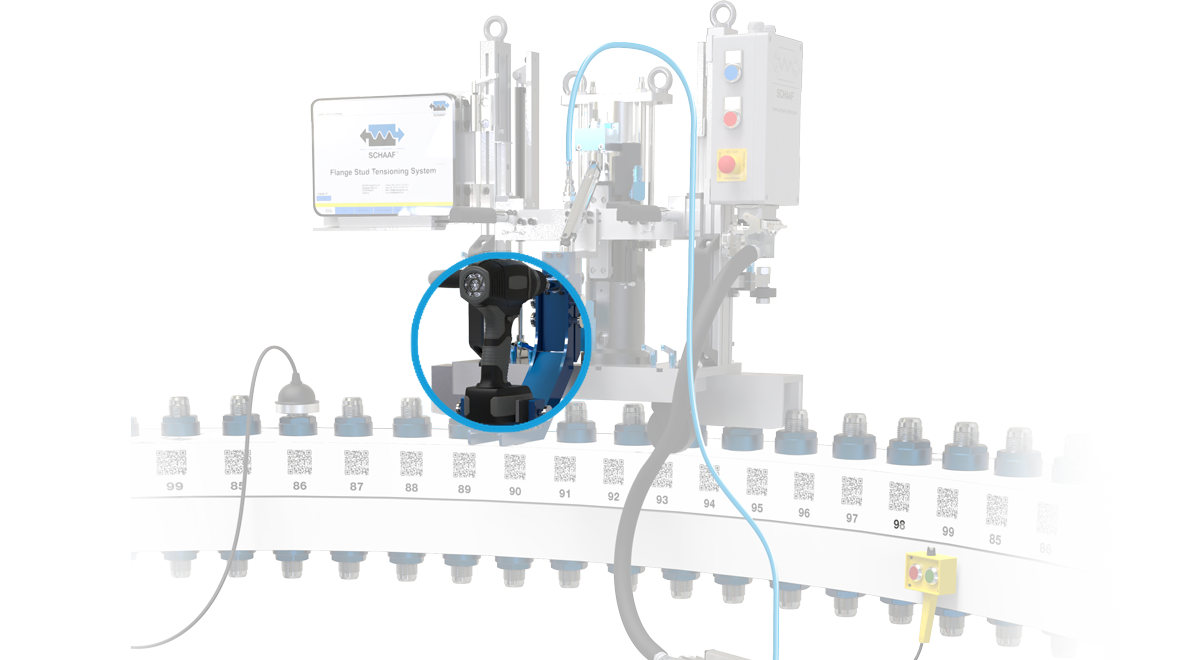

Bolt Tensioner

2,500 bar working pressure with integrated measuring functions.

OBLM

for real time load monitoring

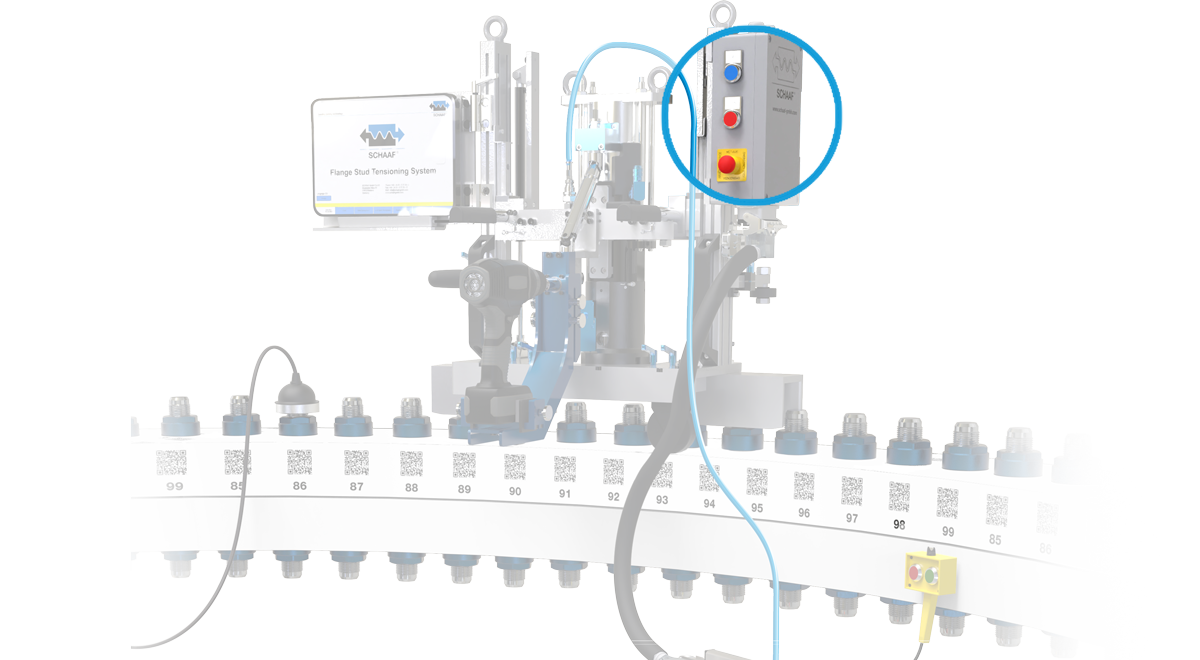

Control unit with Optionally:

· Tool Management System (TMS)

· TSI Tool Service Indicator (TSI)

· Global Tracking (GT)

Universal fixation

for cordless screwdriver

ADVANTAGES

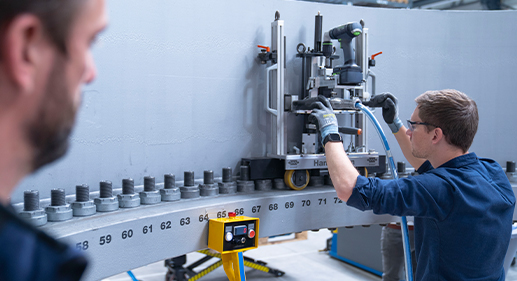

- Optimized Tool design: All parts are designed for min. 100.000 LC. Service interval is 10.000 LC/12 months and preventing collision with obstacles (tower wall, cable tray, ladder, weld seams) for a long life-time and simple handling for the operator

- Suitable for marine and offshore environment: robust against outer influences up to Ip67

- Increased lifetime of the bolt connection: TTG increases the possible residual force of a bolt connection and OBLM is used for real time load monitoring

- Full documentation including bolt elongation, residual force and flange gap evaluation for every bolt connection to achieve maximum security

Versions

All conceivable special designs are possible. Please let us know your requirements.

Areas of Application

SCHAAF FSTS is the optimal solution, where constant monitoring can prevent damages or injuries. Additional estimated bolt loads during design stage can be proved if correct. Especially for connections with permanent vibrations, weather related and temperature changes or load changes, for example wind turbines, bridge construction, cranes, electric generators and motors.

Quality Assurance

All FSTS are checked for 100 % process security. During order handling, they are accompanied by ongoing quality assurance measures and supplied with extensive documentation.

Services

SCHAAF FSTS are user-friendly, reliable, and manufactured in accordance with the highest level of technical know-how. Our highly-motivated staff would be pleased to train your personnel, in situ or at our works, in the general handling and operation of the mobile and stationary control unit. In this way, all the process parameters can be entered optimally in order to achieve maximum process monitoring and safety. Of course, the FSTS are supplied ready for operation.