Hydraulic Nuts (HM)

Hydraulic Nuts (HM)

Hydraulic Nuts do not require a thread projection as Bolt Tensioners do and, therefore, can be used in older constructions to replace conventional torque wrenched bolt connections. For large bolt connections in particular, this eases work and increases the safety of the tension force. Compared with Bolt Tensioners, Hydraulic Nuts enable quicker changing times for connections

that need tightening and loosening on a regular basis. This speeds up checking load forces.

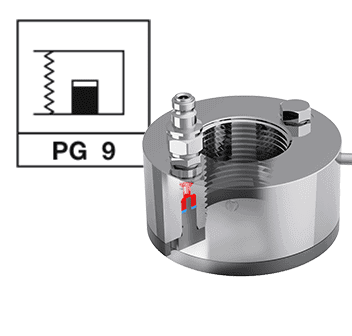

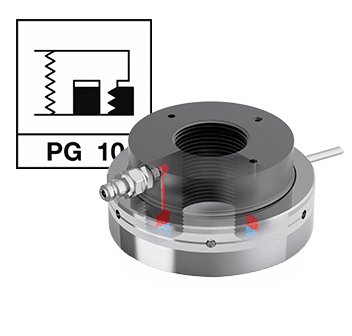

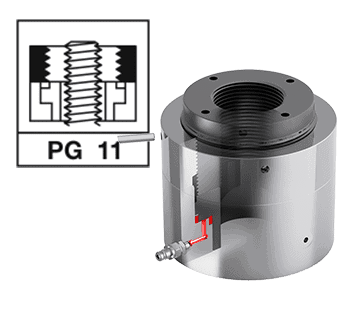

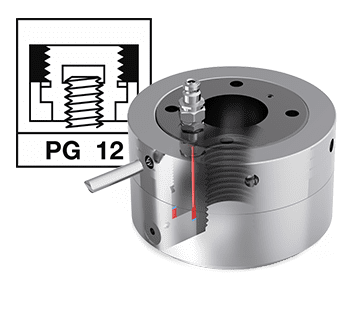

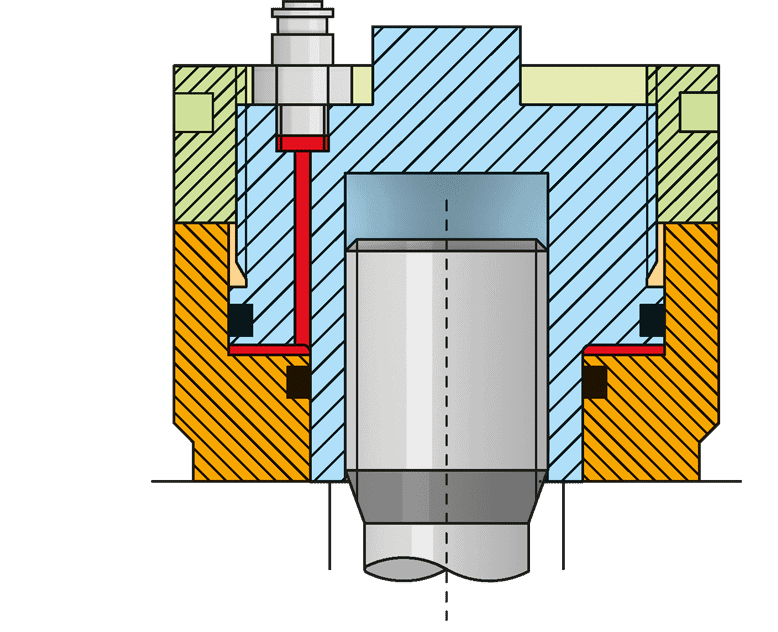

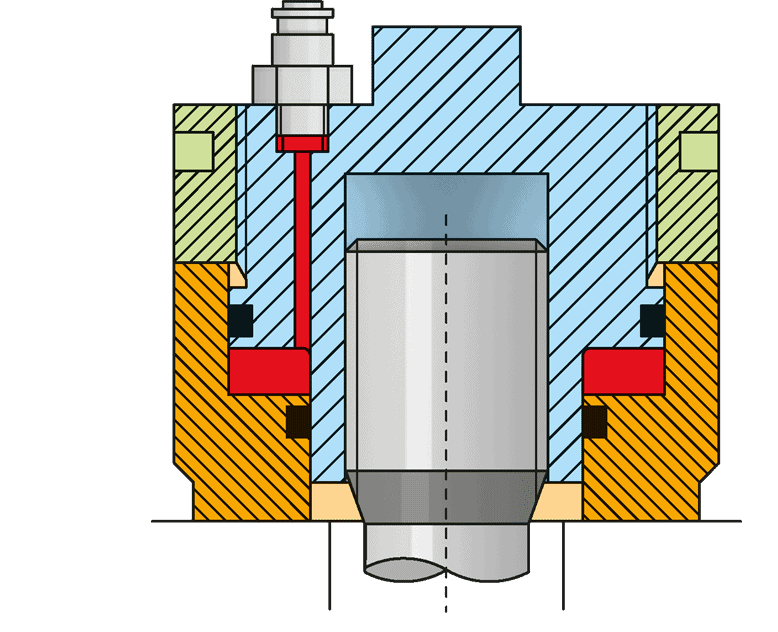

Basic setup

Screw the Hydraulic Nut (HM) on the bolt to be pretensioned, and down to the flanges’ surface. A hydraulic high-pressure generator pumps the oil through a high-pressure hose into the space between cylinder and piston. The hydraulic pressure rises.

Bolt elongation

Through the rising pressure and the resulting axial force, the bolt is elongated and the flange parts are compressed. The lock nut is lifted off the cylinder. When the preset pre-tensioning force is achieved, the pressure supply is stopped.

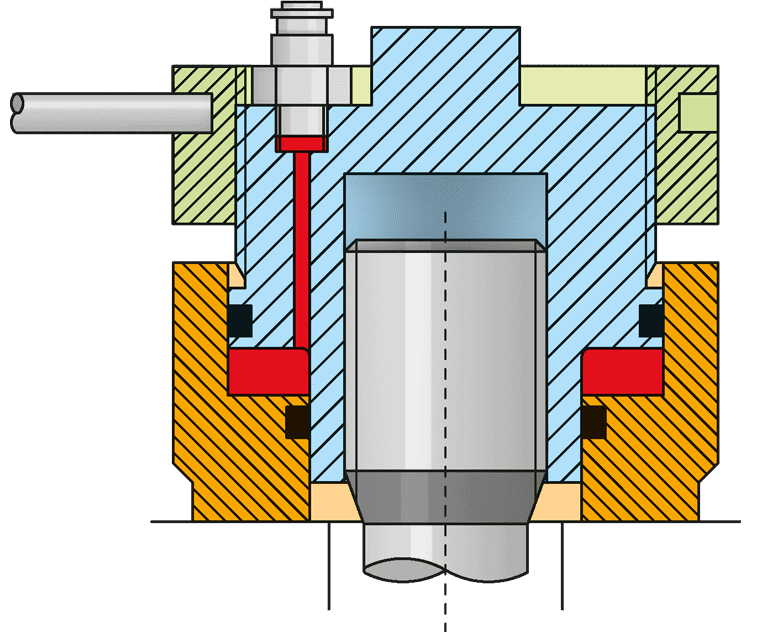

Screwing the lock nut

The pre-tensioning force has been achieved and the lock nut is turned by hand down to the stop face of the cylinder. Thus, the pre-tensioning force is maintained within the screw joint and the hydraulic may be released. The Hydraulic Nut remains on the bolt connection.Overview Hydraulic Nuts (HM)

Unterschiede zwischen:

SSV und HM

- Bolt tensioning devices can be removed from the bolt connection after the pre-tensioning force has been generated. Hydraulic nuts, on the other hand, remain on the screw or component connection.

- The preload force achieved with an SSV is maintained in the screw connection by a machine element (usually a nut). With the HM, on the other hand, the pretensioning force is maintained either by pressure in the HM or without pressure using a mechanical lock (lock nut).

- With the removable SSV, in contrast to the HM that remains on the connection, several screw connections can be preloaded one after the other.

- Fixed hydraulic nuts enable quicker changeover times when tightening/loosening as well as quicker determination of the residual preload force compared to screw tensioning devices.