ExpaTen

With the ExpaTen bolt, SCHAAF GmbH & Co. KG presents a joining element for detachable flange connections of, for example, drive shafts in shipbuilding or in the wind energy sector. The revolutionary, patented concepts of the diverse ExpaTen variants enable the optimum connection for every case. ExpaTen are not only 100% positive-locking and friction-locking, so that high torques can be transmitted without gaps, they can also be easily released and dismantled again after high loads. In addition, this reusable system made of highly tempered steel offers a significant safety advantage in torque transmission compared to normal screws (factor 5). ExpaTen has been certified by renowned inspection authorities.

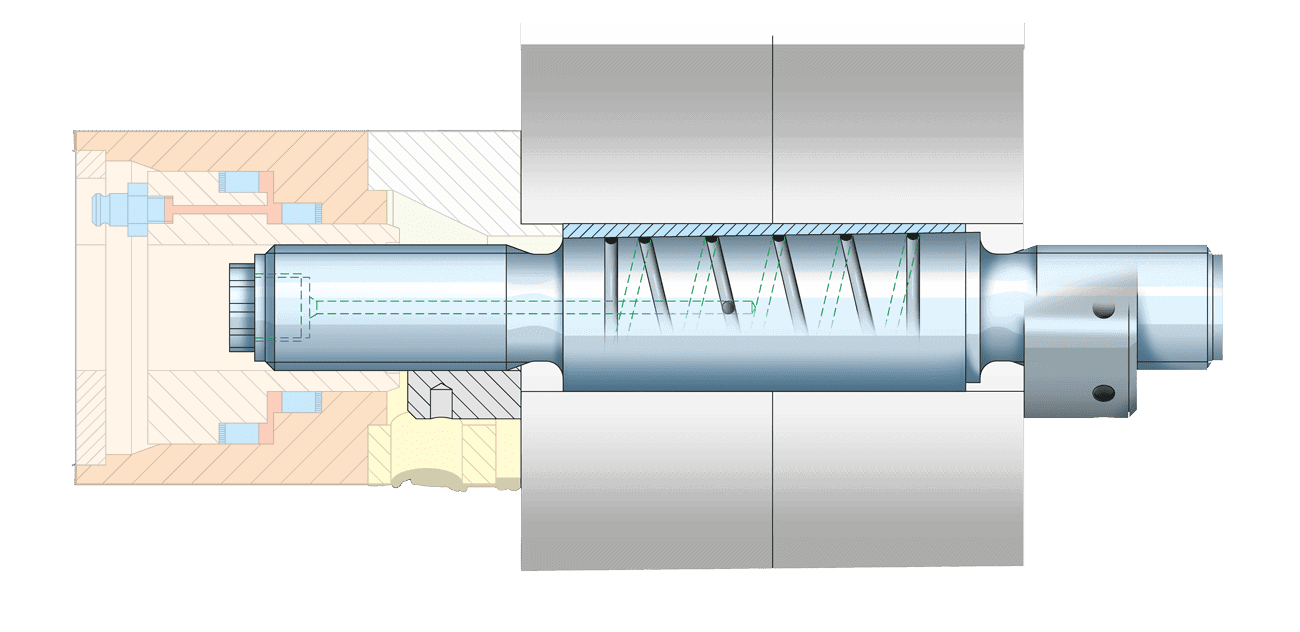

Expa = Expansion = 100% positive locking in the flange bore Ten = Tension = frictional connection for the joint

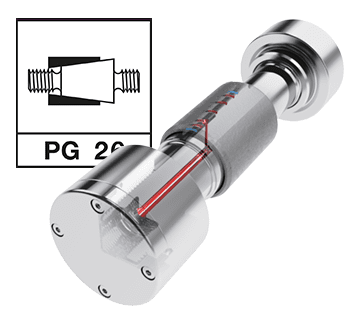

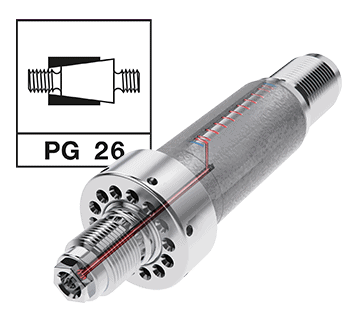

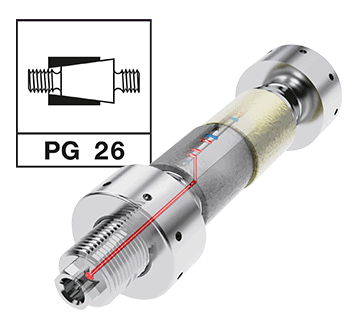

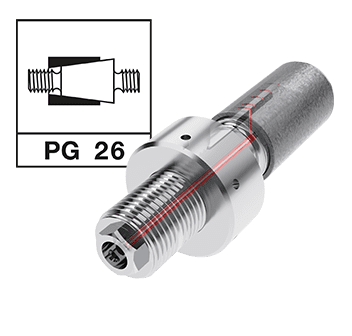

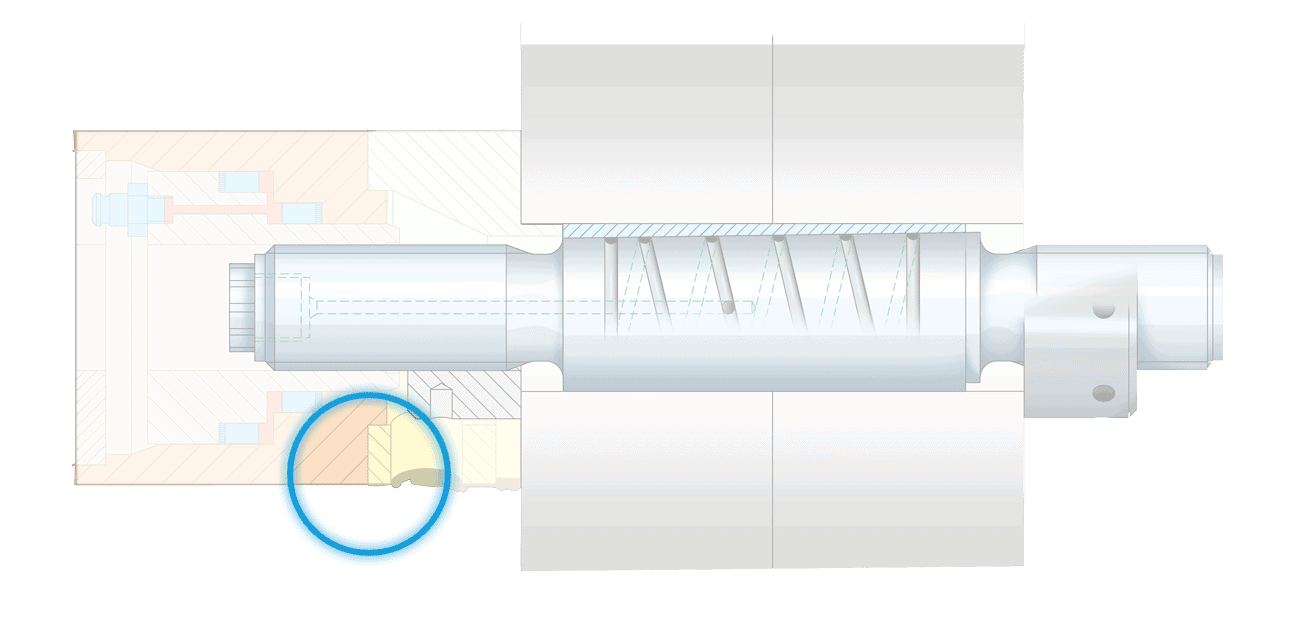

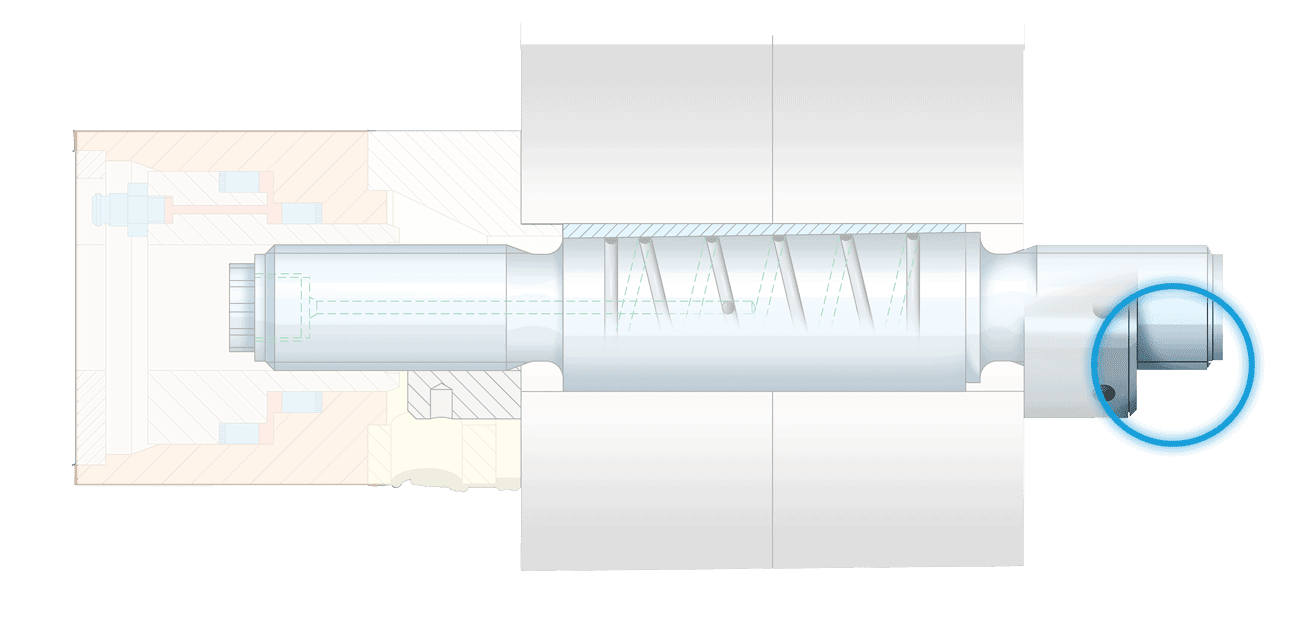

Pressure connection bore

to press out the Tapered Bolt.

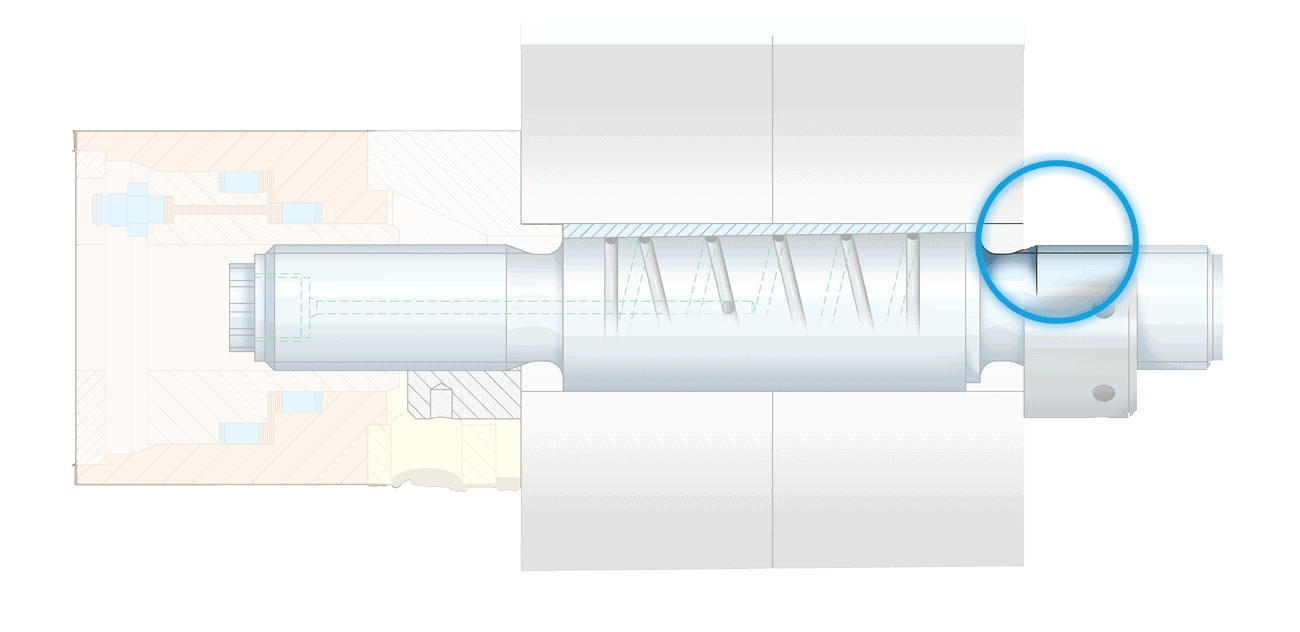

Tapered Bolt made of high-strength quenched and tempered steel

to absorb radial shear forces and a high axial pre-tensioning force

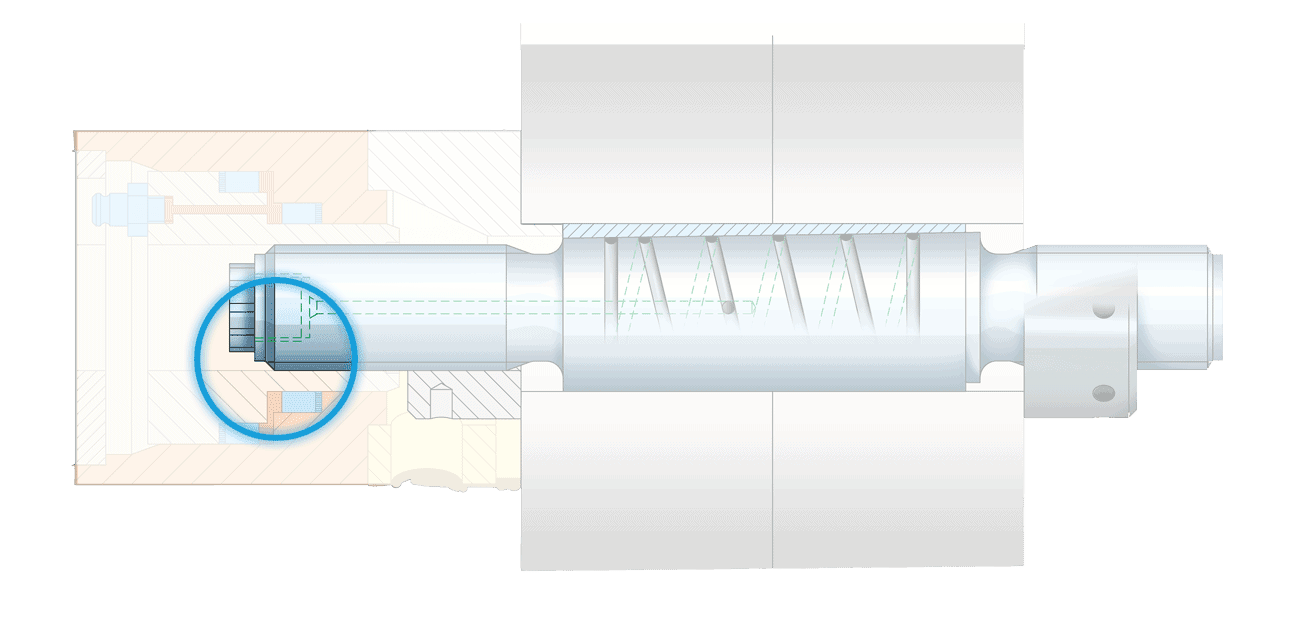

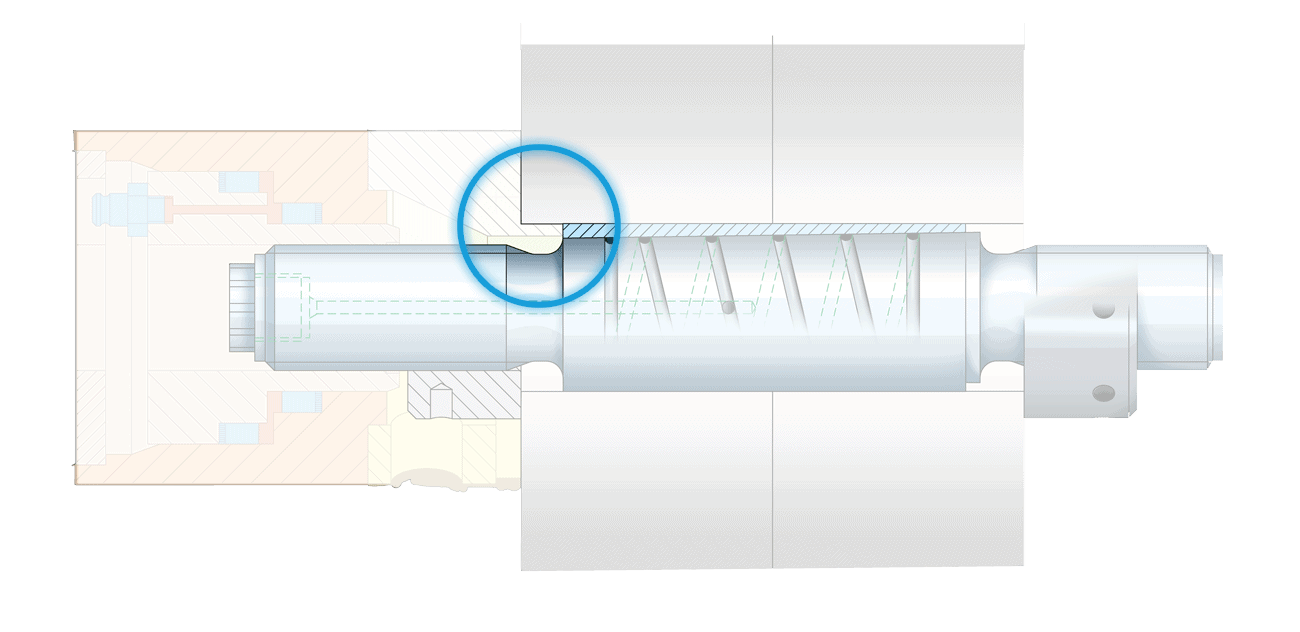

SCHAAF Bolt Tensioner (SSV)

) up to 4000 bar hydraulic pressure.

Positioning ring to hold the Conical Sleeve

in position while the Tapered Bolt is being pulled into the Conical Sleeve. This results in expansion (Expa) of the sleeve and produces a press fit in the bore

Guaranteed reusability

y even after years of use. Again and again.

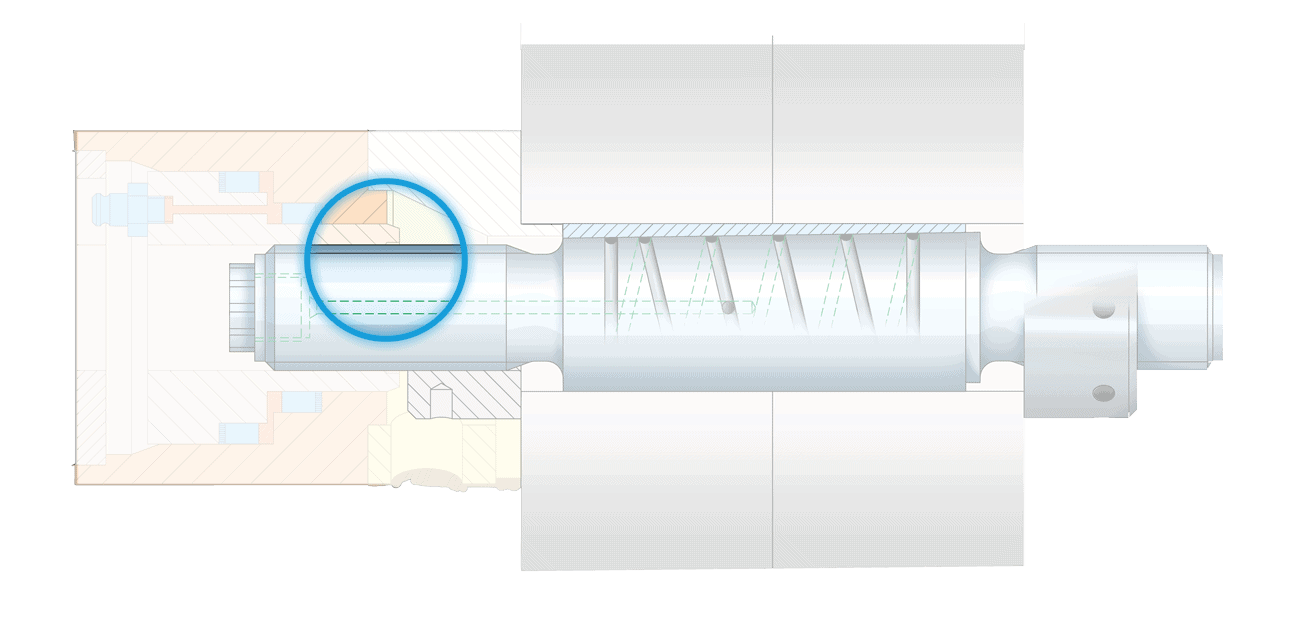

Pressure distribution grooves on the taper

to allow easy removal even after years of use.

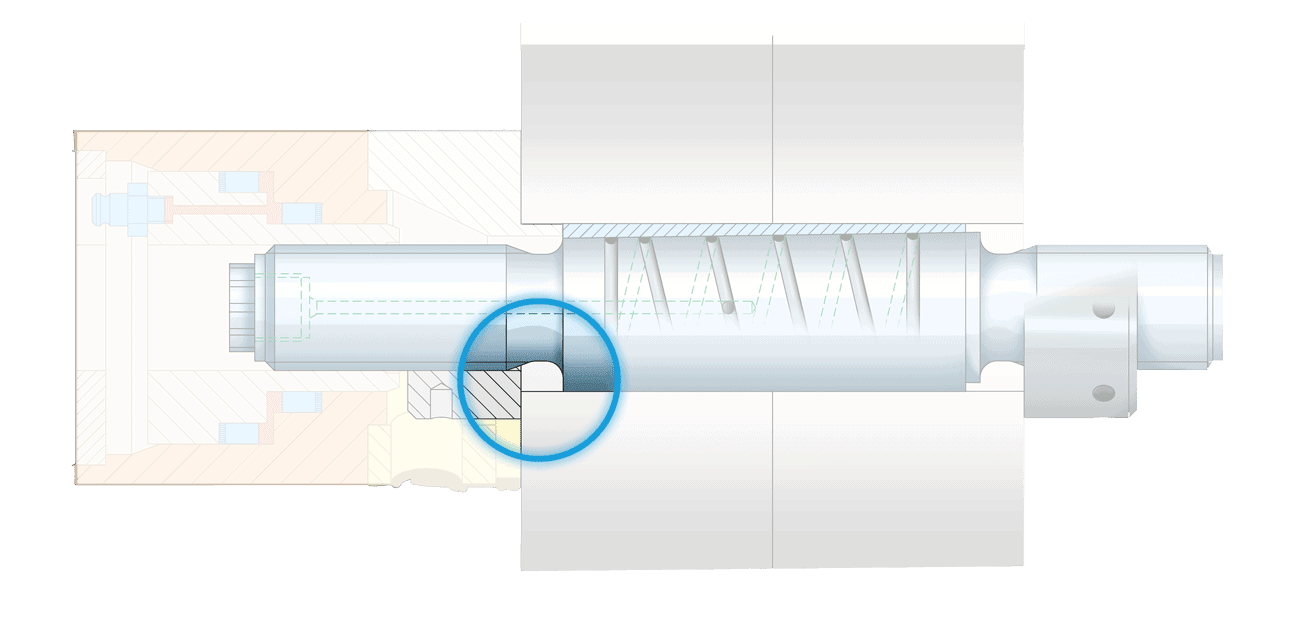

Conical Sleeve

of high tensile and ductile steel for maximum shear strength.

Two Round Nuts and Tapered Bolt

with ultrahigh-strength material for maximum fatigue strength.

Overview ExpaTen

Quick form and force fit connections with detachable axial tensioning system (Quick Locking).