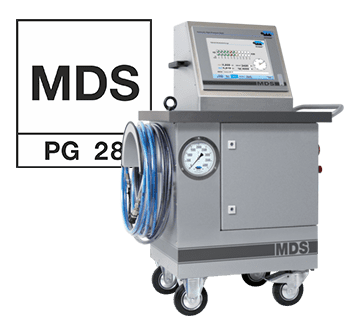

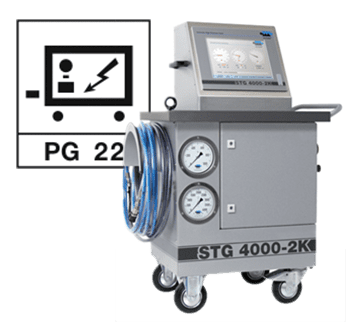

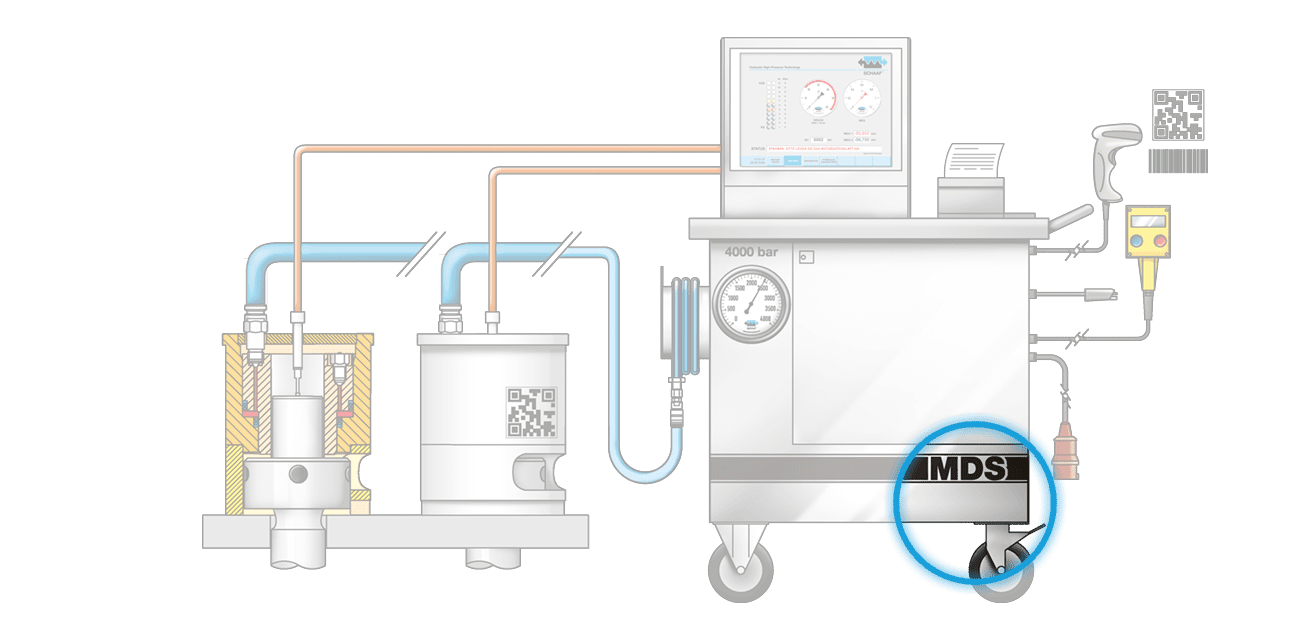

MDS

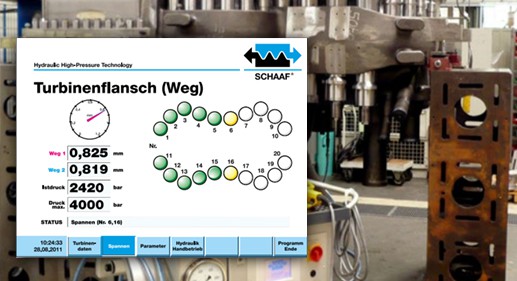

Mounting Documentation System for control and monitoring of the axial, hydraulic bolt-tightening process.

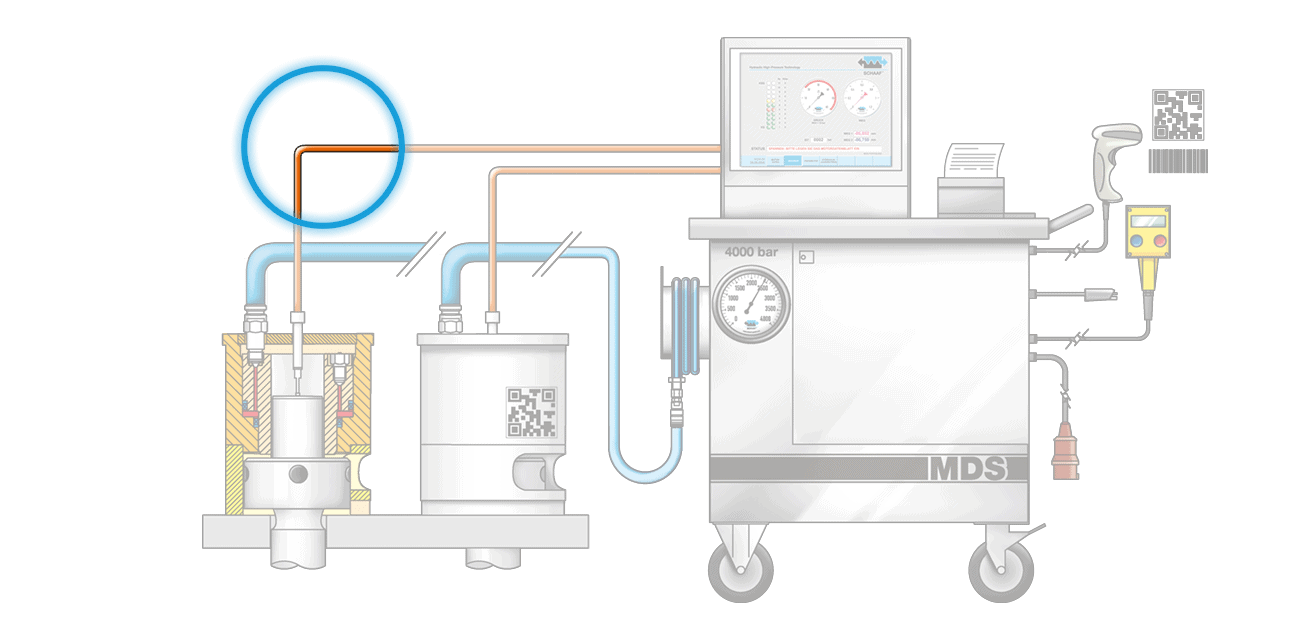

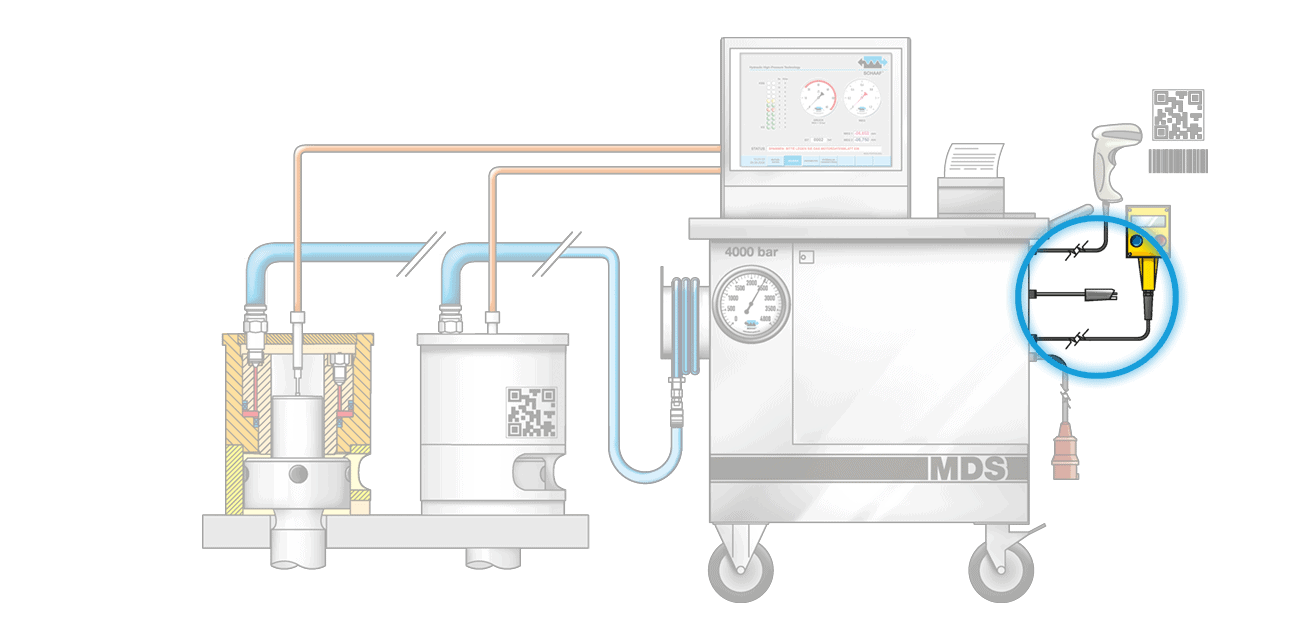

Position sensor

for determining the bolt elongation and flange compression

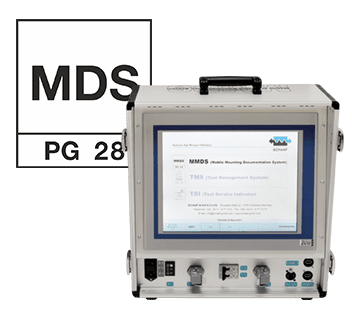

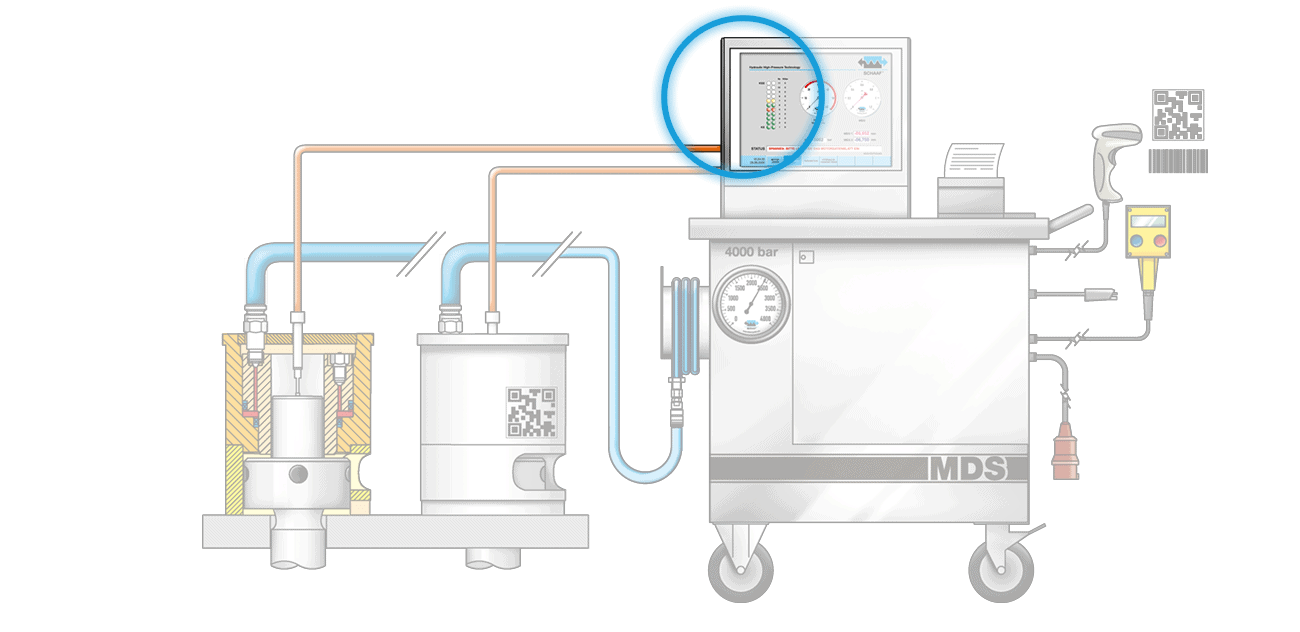

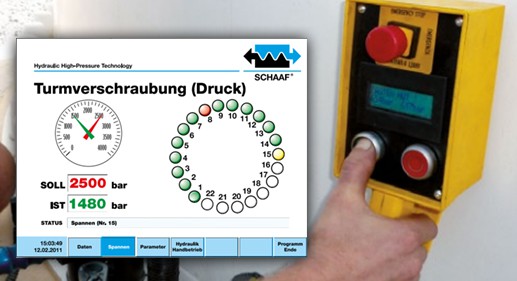

TFT touch-screen

for monitoring and operation.

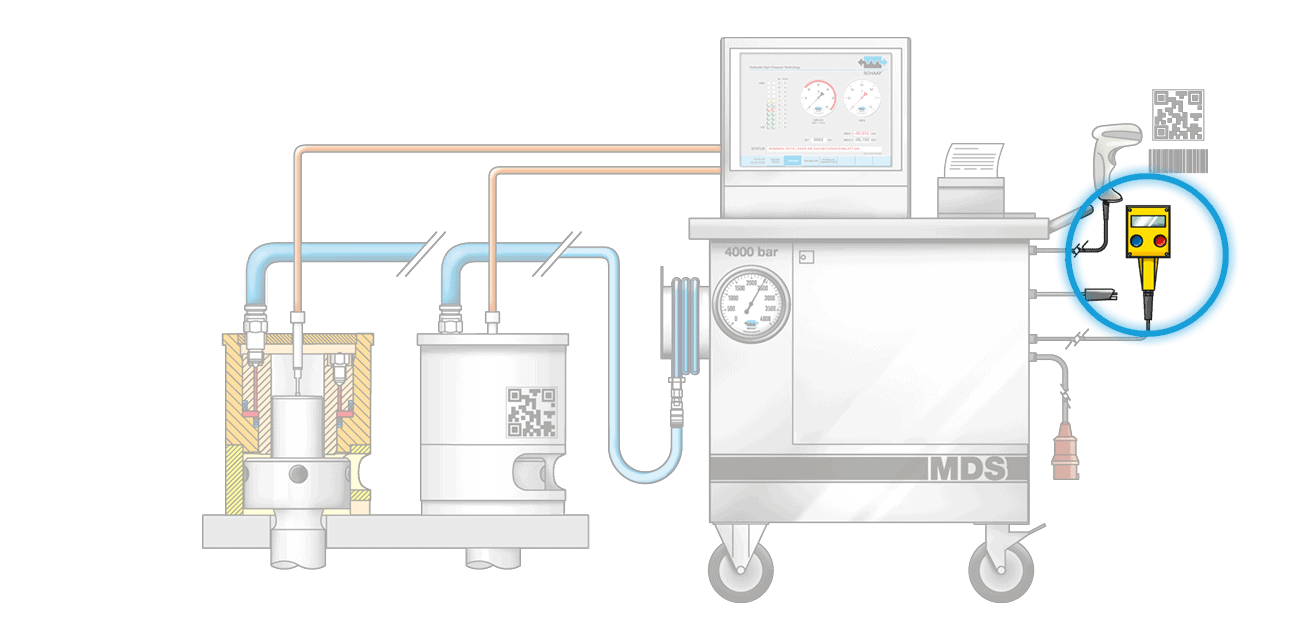

Bar-code reader/data-matrix

for selection of the appropriate application and recognition of the tools used (TMS).

High pressure hoses

with couplings for a hydraulic pressure of up to 4000 bar.

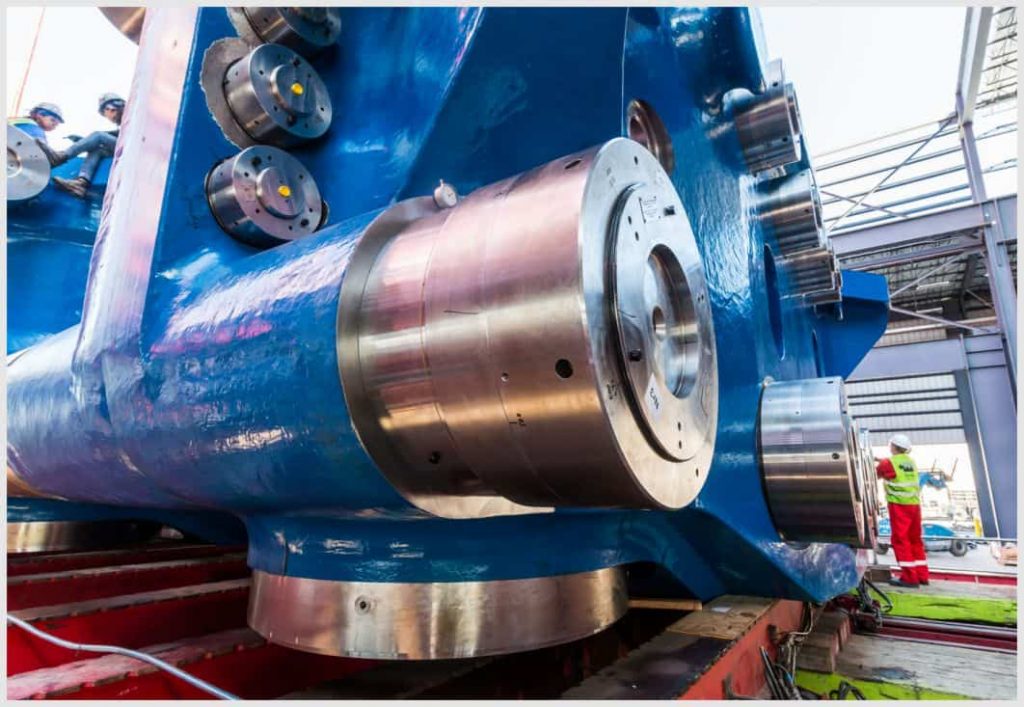

Bolt tensioner(s) for pre-tensioning,

, including elongation and/or hydraulic pressure monitoring.

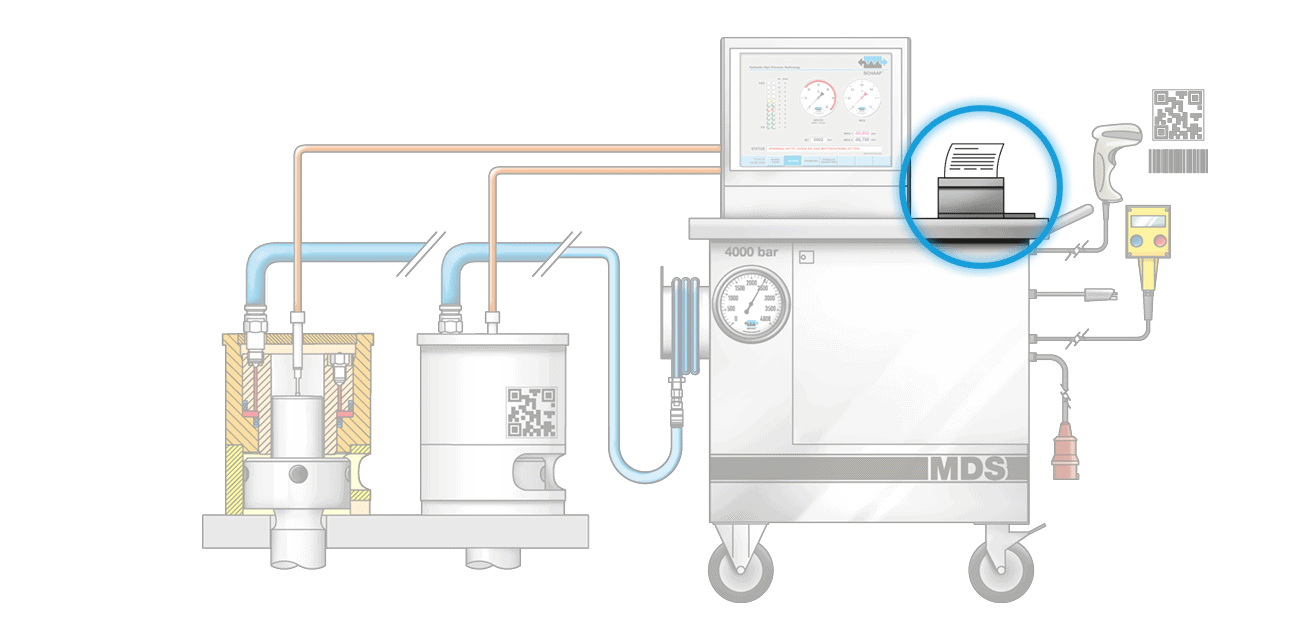

Industrial printer

for direct output.

Stable, mobile casing

with integral pressure generator and control system.

Central data processing via LAN, W-LAN or USB stick,

optionally provided with Tool Management System (TMS).

Manual operating unit with display

Advantages

- 100% documented quality of bolt connections

- Increased work safety thanks to frequent pressure and elongation characteristic monitoring (according to Hooke‘s Law)

- Automatic shutdown in case of process errors

- Guarantee of the correct bolting load

- Ability to prove that the generation of pre-tensioning force was correct in the event of damage thanks to documented logging of the tension positions and pressures and clamping procedure

- Self-monitoring of the MDS by means of integral self-test and redundant pressure transmitter monitoring

- Simple, clear and comfortable user interface that leads through process

- Automated control of multiple pressure circuits in accordance with different pre-tensioning force generation programs

- Over 60,000 original data sets of tightening parameters can be stored

- Password-protected parameter input

- Simple copy and paste of new data sets for new bolting conditions

- Mobile or fixed units possible

- Operator guidance in selectable language

- Long service lifetime and user-friendly maintenance intervals

- Integral Tool Service Indicator (TSI)

- Optional Tool Management System (TMS)

- Ideal for individual or series assembly– rapid pre-tensioning force generation

- Data output as diagram or table

- Data output on customer quality assurance sheets

- Precise pressure generation with a tolerance

- of ± 10 bar at 4000 bar. More precise pressure range regulation in various pressure ranges according to customer requirements.

- Almost unlimited capability for archiving of tightening procedures for individual or complete bolt-tightening systems

- Assembly errors are eliminated due to integrated process guidance

- High load-cycle values and long lifetime

- Tensioning programs and reports can be transferred via USB or LAN-Access

Suitable for engine manufacturing

The SCHAAF Mounting Documentation System (MDS) is a pressure generator that documents the tightening procedure for bolted joints. This ensures 100% verifiability of the joint quality. The material homogeneities are monitored (according to Hooke‘s Law) during generation of the pre-tightening force. This involves monitoring of the pressure – elongation curve. All additional quality parameters can be specified individually and the system meets the tightening specifications and shuts down automatically when an error appears.

Suitable for the wind power industry

The SCHAAF Mounting Documentation System (MDS) is optimised for mobile and standard applications when building and servicing wind power plants. As soon as the parameters for bolting conditions are entered they become available to the operator. The text display ensures that the operator can create an assembly with 100% reliability – even in the case of problematic bolting conditions. All cases are saved in the assembly guide system so that even inexperienced workers can always achieve 100% quality during assembly.

Suitable for turbine manufacturing

The SCHAAF Mounting Documentation System (MDS) is controlled by a digital database that is specific to each turbine installation. All process data are accessed from the digital database and the entire tightening procedure is documented – even in the case of stepwise increase of the pre-tightening force. Operation is carried out by the separate remote control unit and can be performed from great distances due to its large display. Pressurisation to the specified values can be effected very rapidly because the SCHAAF high pressure equipment has a very high rated flow capacity.All high-pressure units

Mounting Documentation System for controlling and monitoring the axial hydraulic tightening process of bolts.

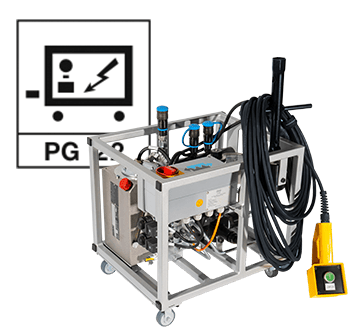

Electro-hydraulic two-circuit high-pressure automatic control system for fully automatic pressing of hubs onto shafts and separating

Versions

- Colour or B+W printer

- Radio-operated remote controller with display

- LAN/W-LAN/USB interface

- Remote access for remote maintenance

- TMS interface (Tool Management System)

- TSI interface (Tool Service Indicator)

- Radio-operated sensors

- Sensors integrated in the bolt tensioners or supplied separately

- Central specification of bolting data via SAP interface, database, USB interface or copy and paste

- 1-3K design type for separate control of multiple independent pressure circuits

- Rotation angle and torque control for bolt tensioners with automated motorised re-tightening function

- Optional colour coding of the used equipment

Areas of Application

- Generating a bolt pre-tensioning force for which 100% operational sequencing, safety and data logging are required.

- Engine-building: Main bearing, connecting rod bearing, cylinder head

- Power plants: e.g. Turbines, compressors

- Ring gear bolt connections: e.g. wind power plants

- Tower fittings: e.g. crane construction

- General mechanical engineering

Quality Assurance

All MDS are checked for 100 % process security. During order handling, they are accompanied by ongoing quality assurance measures and supplied

with extensive documentation.

Services

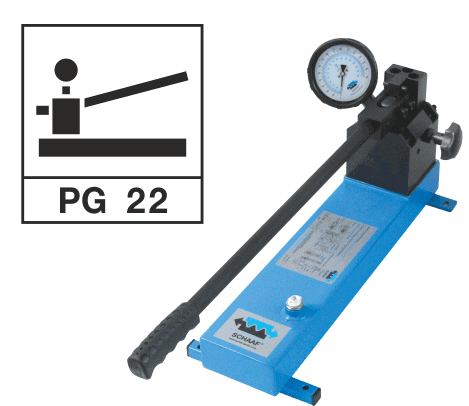

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.