GripCon

The optimum component connection

Cost reducing – Powerful – Unique

SCHAAF GripCon utilises all the leading design principles and benefits of ExpaTen and takes the design and performance of hydraulic coupling bolts to a new level. Designed for weight, cost and space saving applications, GripCon maximises product safety, reliability and overall performance for all power bolt connections.

The patented SCHAAF design technology offers a lifetime warranty, even after multiple installations and removals.

Form fit component connection

which takes up highest axial and radial loads

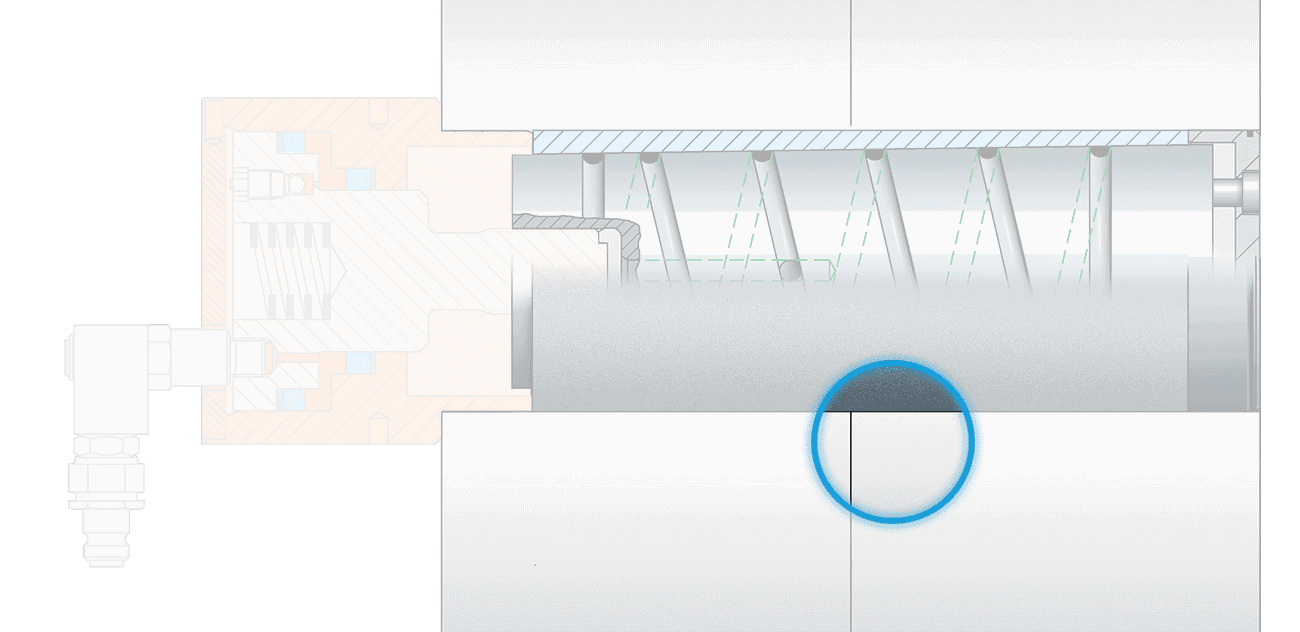

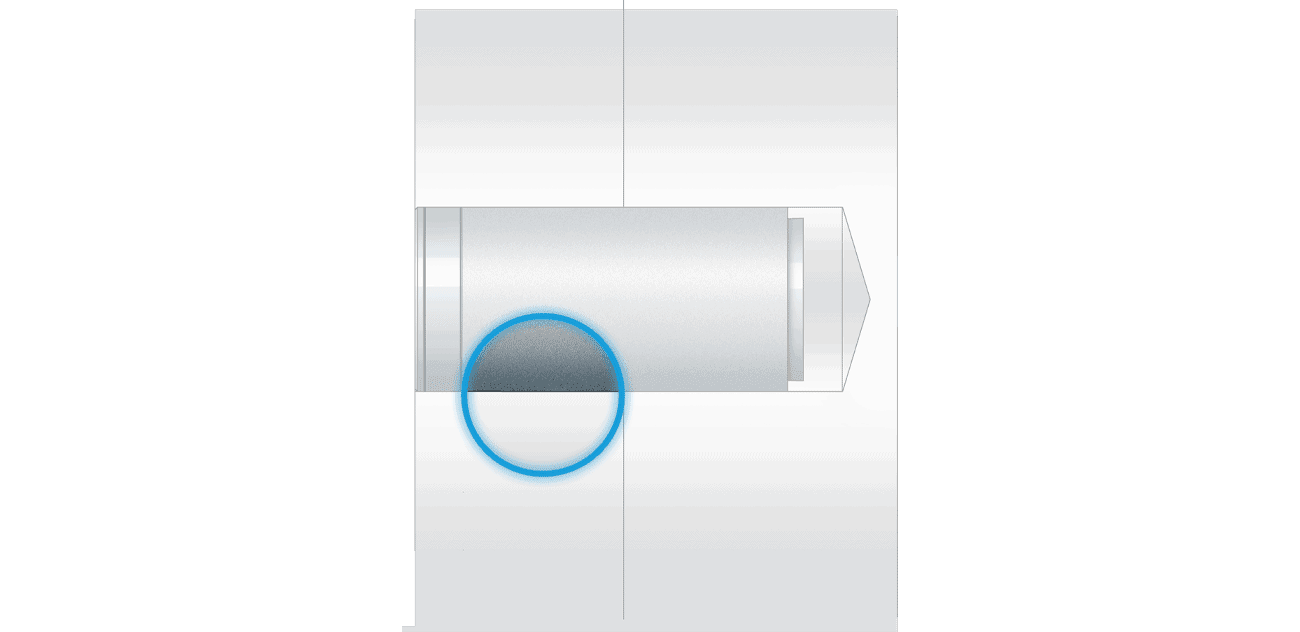

SCHAAF GripCon mounting cylinder

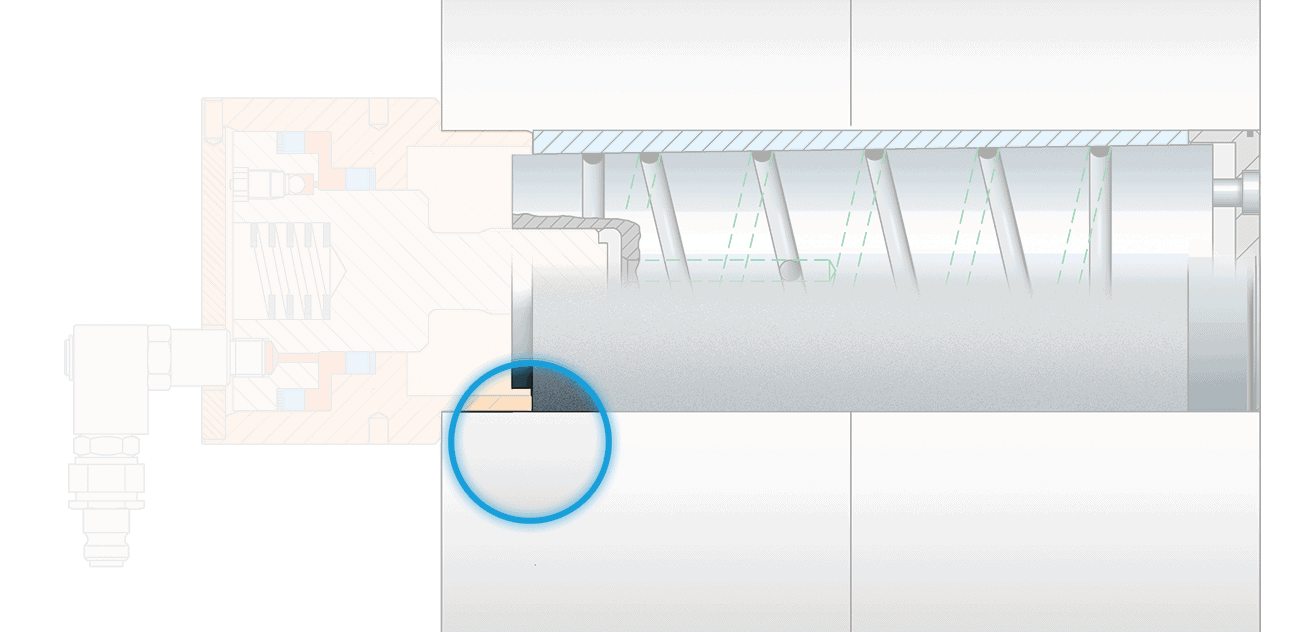

Positioning ring

for fixation of the Conical Sleeve while the Tapered Bolt is pulled into the Conical Sleeve. Expansion of the Conical Sleeve, gives a press fit and interlocking into the bore is the result.

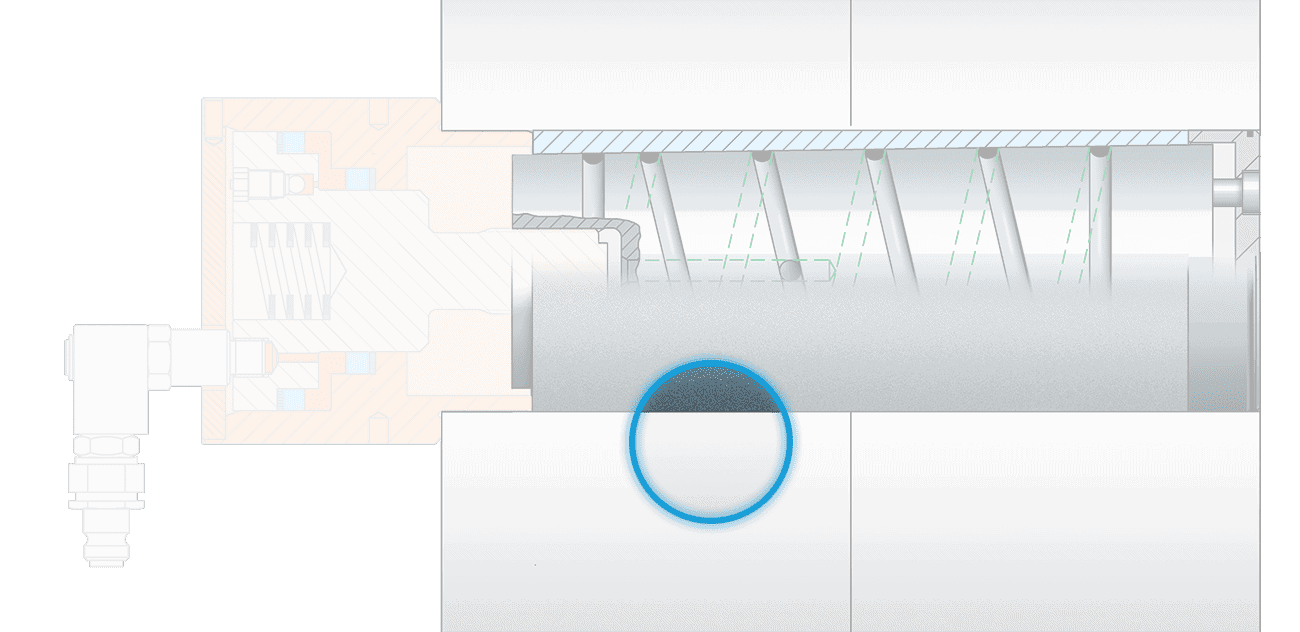

Connecting bore

e for assembling and dismounting of GripCon

Guaranteed reusability

y when dismounted even after years of use. Again and again.

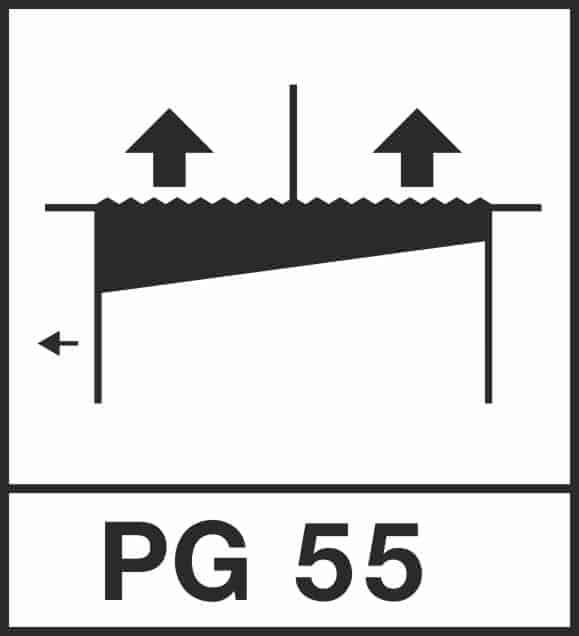

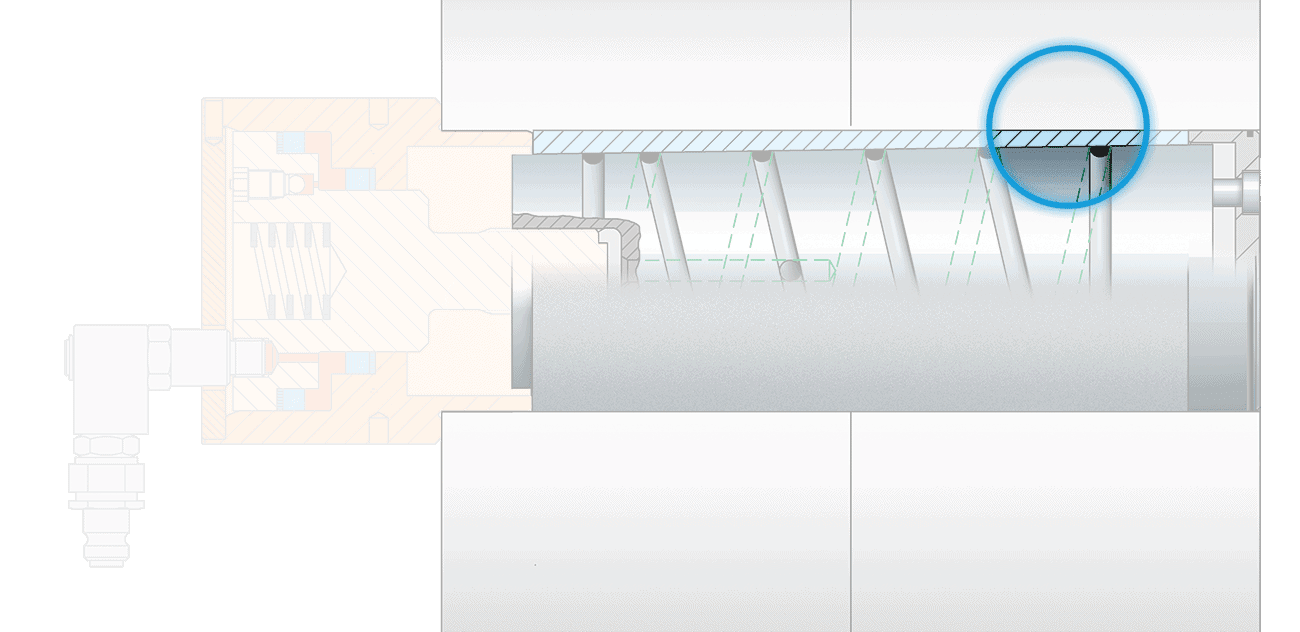

Pressure distribution grooves on tapered surface

for easy removal and installation even after years of service

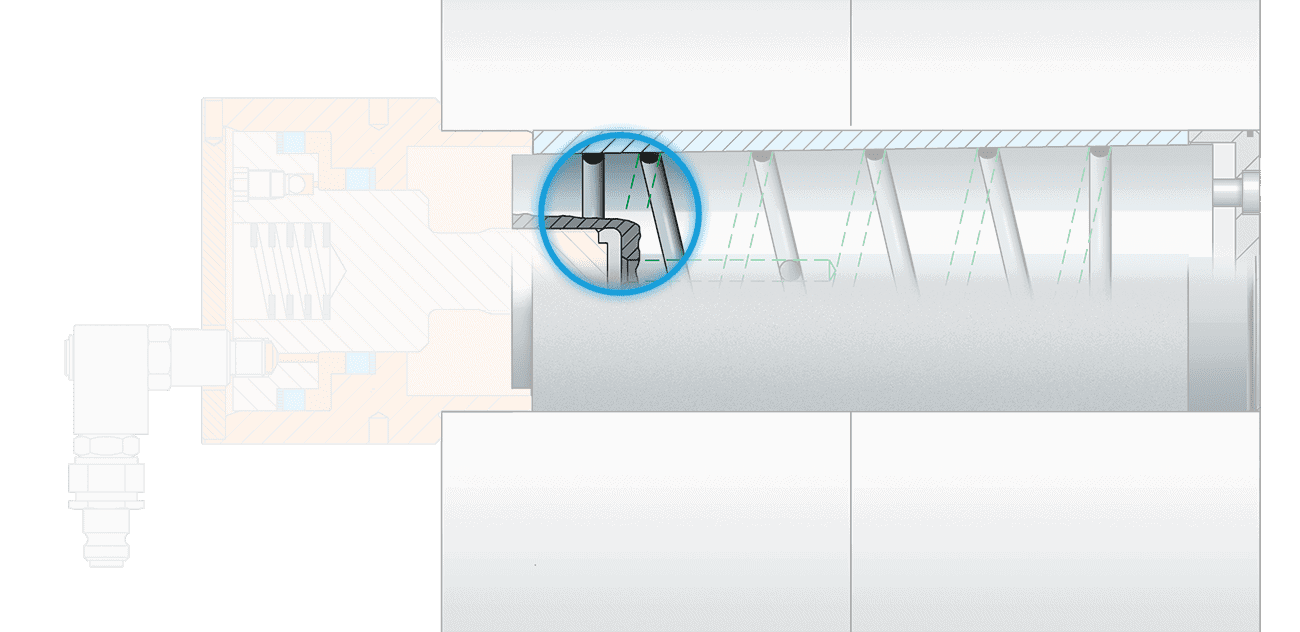

An internally Conical Sleeve and Tapered Bolt of high strength steel

for transmitting radial shear forces and high axial forces.

µ ≥ 0,9 friction coefficient

between Conical Sleeve and bore wall.

Advantages

- 100 % form fit and frictional connection anytime after mounting, no slipping of flanges

- No nuts for flange connections, thus significant cost reduction

- An approximate 50 % weight reduction

- Lower manufacture investment for significantly less connection elements

- No more thread cutting in stud holes necessary

- No protruding threads or nuts – better design and higher efficiency of rotation machines

- No protruding threads or nuts – better design and higher efficiency of rotation machines

- No conventional bolt connection elements

- Significant mounting time reduction because of less connection elements

- Significant less mounting and dismounting space needed

- Simple and quick installation and removal of GripCon even after years of use

- Reusability after removal again and again – no spare parts necessary

Versions

- No conventional bolt connection elements

- Significant mounting time reduction because of less connection elements

- Significant less mounting and dismounting space needed

- Simple and quick installation and removal of GripCon even after years of use

- Reusability after removal again and again – no spare parts necessary

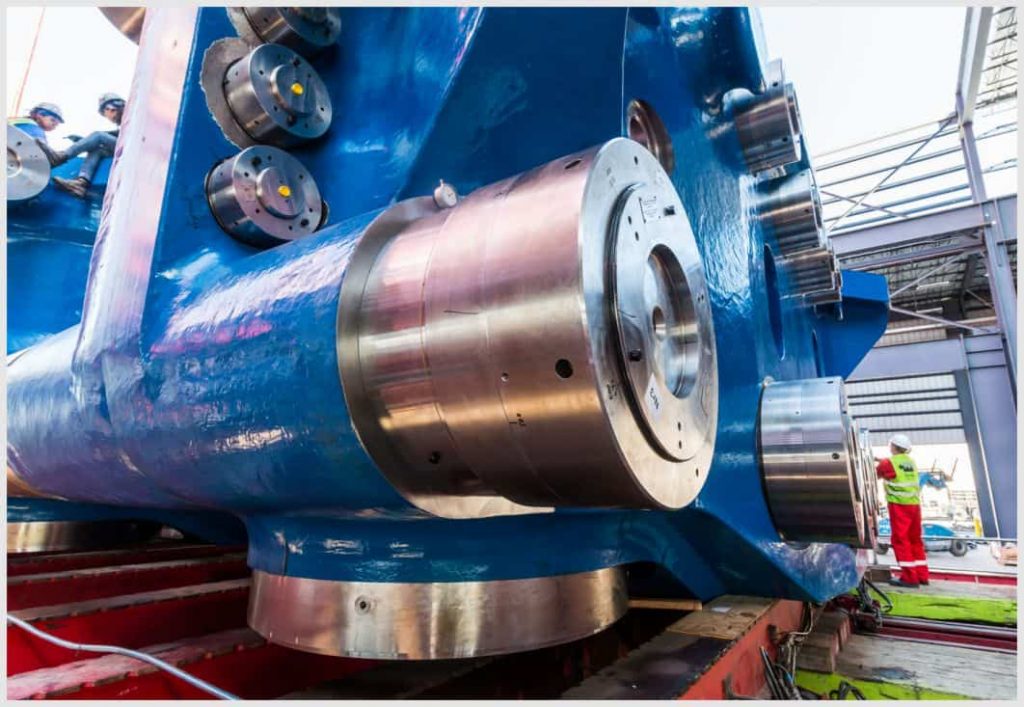

Areas of Application

SCHAAF GripCon are the optimum solution wherever high forces (axial and radial) must be transmitted in smallest construction spaces and, at the same time, easy removal must be ensured, for example ship drive shafts, flywheel fixings for large motors, gear box manufacturing, heavy equipment manufacturing and wind power plants.

Quality Assurance

All GripCon are checked for material quality, dimensional accuracy, correct functioning and load-resistance. During order execution, they are subject to continuous quality assurance measures and are supplied together with detailed technical documentation.

Services

GripCon are, of course, supplied packaged, ready for installation and use.

SCHAAF GripCon are user-friendly, reliable, and manufactured in accordance with the highest level of technical know-how. Our highly-motivated staff would be pleased to train your personnel, in situ or at our works, in mounting and dismantling the bolts.

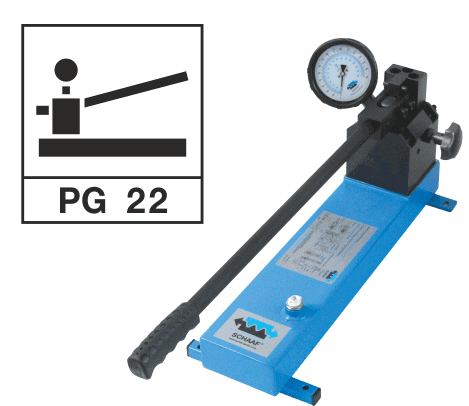

Related Accessories

Fully assembled and ready for immediate use Hand lever pump up to 4,000 bar hydraulic pressure.