Further development and design of a flange connection element for increased bore offset

sgeissler2020-10-01T06:11:33+00:00The “GripCon” connection element developed by SCHAAF is the ideal solution when large forces in a flange connection have to be transmitted in the radial direction and additional forces in the axial direction.

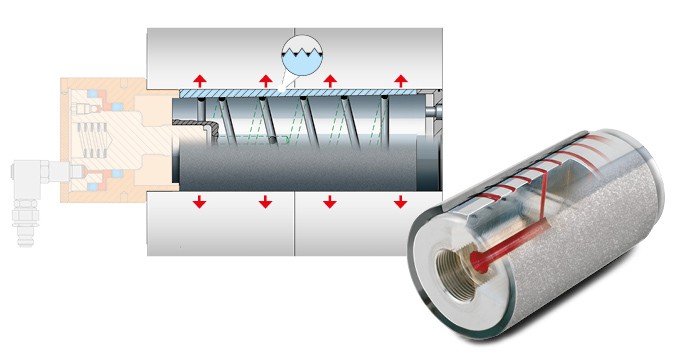

GripCon creates surface pressure on the inner wall surface of the bore, which is applied by radial expansion of a conical sleeve. A friction-increasing coating on the outside of the GripCon also increases the axial power transmission. Two or more flanges with GripCon elements can be connected positively and by form fit – without the use of screws and nuts. The geometric and thus also physical savings of the entire connection are the great advantage of the GripCon technology. In addition to the reduction in flange dimensions, no protruding elements such as screw heads or nuts are required. The compact design of GripCon also reduces the space required for installation and removal. GripCon can be assembled and disassembled several times without damaging the flange holes or the GripCon itself.

In order to be able to achieve further savings potential for the customer in the area of flange manufacturing costs, the maximum permissible offset of the flange bores should be determined and GripCon constructively adapted. The current technical advantages and power transmission options of GripCon should continue to exist.

The work to be done deals with the analytical determination and calculation of the bore offset, the design of a further developed GripCon and the implementation of test series with possible solutions. The developed concept is presented to potential customers and further improved together.