MDS and Bolt tension for offshore wind turbine

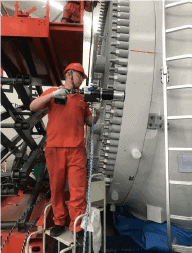

sgeissler2021-10-13T09:26:35+00:00In May of 2018, SCHAAF received the order for the delivery of MDS (mounting documentation system) and smart bolt tensioner for offshore wind turbine assembly. The MDS and tensioner will be used for tensioning the bolts on the pitch bearing, the bolt elongation and residual bolting force will be documentated as quality report. Most customers just use torquing method or rely on the hydraulic pressure to tension the bolt, this is not sufficent especially for offshore wind turbine bolting. Our customer can increase the bolting quality and safety by using our MDS and smart tensioning system. The mounting can be done easily, minimum four workers are required and the mounting can be done within one hour for one pitch bearing. Used SCHAAF products for this 8 months (long) project were the smart tensioner M42, MDS with operating software and a high pressure hose with 1600bar. The smart tensioner is equipped with a bolt elongtion measuring system, light weight design for horizontal operation. The bolt mounting pressure, bolt elongation, bolt residual force are documentated as quality report by using MDS. The MDS has high capacity and efficiency, pressurization can be done within 10-12 seconds. All the tools are durable and have the highest safety for workshop assembly. By using the smart tensioner and MDS, the flange bolting data is fully documentated. You will get the mounting report showing the bolting residual force of the whole pitch bearing. This makes sure, that assembly reaches the design requirement and also increases the safety especially for offshore wind turbine. This technology can also be used for yaw bearing bolts, blade bolts and tower bolt tightening. Moreover, the MMDS (mobile mounting documentation system) can be provided for field assembly.